Electrical Engineering

Projects

Electrical and Computer Engineering ECE 480 Senior Design is required of all electrical and computer engineering majors at MSU.

For information on becoming a project sponsor, please contact Gregg Motter.

The following were the project sponsors and projects for Spring 2017:

NDE Lab at Michigan State University: 3D Sensing Platform

Non-destructive examination is a group of analysis techniques used in industry for evaluating the integrity of a material, component or system without causing any physical damage. NDE is used as quality control in advanced manufacturing. There is a wide choice of measuring techniques available to meet the demand of examining a wide variety of materials such as metals, plastics and rocks, as well as different structures and sizes ranging from semiconductor chips to nuclear reactors. At the same time, physical measuring techniques are used to examine parts of construction assemblies for hidden imperfections and defects.

Non-destructive examination is a group of analysis techniques used in industry for evaluating the integrity of a material, component or system without causing any physical damage. NDE is used as quality control in advanced manufacturing. There is a wide choice of measuring techniques available to meet the demand of examining a wide variety of materials such as metals, plastics and rocks, as well as different structures and sizes ranging from semiconductor chips to nuclear reactors. At the same time, physical measuring techniques are used to examine parts of construction assemblies for hidden imperfections and defects.

The NDE Laboratory asked our team to design a single-channel, multi-band, and multi-resolution sensing system that includes a prototype of a single-channel probe and a platform that is geometrically flexible for complex structures and materials that can move sensors in an x-y-z direction. Two sensors: 1) LiDAR, to plot the 3D surface image of the object, and 2) microwave sensor, to show the surface and subsurface of the object, will be implemented in this platform. VNA will be used to integrate the signal from EM sensors at different frequencies, and we will develop a software to collect the data and process it into images.

MSU Electrical & Computer Engineering:Human-Robot Integration System

Michigan State University is interested in developing a human-robotic integration system. This technology will use human gestures and eye-movement to control a ground robot, providing solutions in a wide variety of applications. It could be used to aid in the mobilization of the physically disabled, where paralyzed individuals could transport themselves using limited body movement. The system could also be used in industry to explore or operate under conditions not suitable for humans. Whether the application is the deep sea, outer space, or in your living room, humans and robots need the capability to communicate effectively. A human- robot integration system aims to accomplish this task. There is a lot of potential for a system like this.

Michigan State University is interested in developing a human-robotic integration system. This technology will use human gestures and eye-movement to control a ground robot, providing solutions in a wide variety of applications. It could be used to aid in the mobilization of the physically disabled, where paralyzed individuals could transport themselves using limited body movement. The system could also be used in industry to explore or operate under conditions not suitable for humans. Whether the application is the deep sea, outer space, or in your living room, humans and robots need the capability to communicate effectively. A human- robot integration system aims to accomplish this task. There is a lot of potential for a system like this.

Our team is particularly focusing on developing an eye-tracking system and a head-motion tracking system to control the robot and a camera mounted on it. This will involve two subsystems responsible for different types of commands. The head motions detected with the system correspond to different movements of the physical robot. The eye-tracking system will measure the user’s eye positions to control movement of the robot’s camera, and the robot’s camera will send the real-time video footage back to the computer. Then, the computer will display the video footage on the screen so that the user has a clear idea of what the robot is looking at and where to move it accordingly.

Team Members (L-R): Abdulrahman Kamil, Hanchen Xie, Christopher CUmmings, Matthew Price, Steffany Ellenstein, Yaoting Xu

Michigan State University: Quadcopter with Robotic Arm

Nowadays Quadcopters are being used increasingly in a wide variety of applications. They can easily travel to heights humans can not easily reach, and they can travel across great distances.

The purpose of our project is to design a Quadcopter that is capable of autonomous flight and that has the functionality of transporting different objects. The basic task for the Quadcopter is to transport a 30g object with its robotic arm to a specific location and to achieve a flight time of at least 8 minutes.

The purpose of our project is to design a Quadcopter that is capable of autonomous flight and that has the functionality of transporting different objects. The basic task for the Quadcopter is to transport a 30g object with its robotic arm to a specific location and to achieve a flight time of at least 8 minutes.

The Quadcopter will include a Flight Control Unit (FCU) for autonomous flight. The FCU communicates with onboard sensors such as a gyroscope, an accelerometer, and a barometer to keep the copter stable in flight. To navigate, the FCU also communicates with information from external sensors such as cameras or GPS, depending on whether the flight is indoors or outdoors. The FCU also communicates with an Arm Control Unit (ACU) to tell the arm where an object is and when to pick it up. Our final designed product will satisfy all the requirements and minimize the cost of our Quadcopter system

Michigan State University: Diamond Surface Measurement

Diamond has numerous electronic properties which make it very attractive in semiconductor technology. Compared to the most common semiconductor material used today (silicon), diamond is superior in many aspects. The process of growing diamond is accomplished by a chemical vapor deposition process and MSU’s ERC has been a part of this process since the early 1980’s.

Diamond has numerous electronic properties which make it very attractive in semiconductor technology. Compared to the most common semiconductor material used today (silicon), diamond is superior in many aspects. The process of growing diamond is accomplished by a chemical vapor deposition process and MSU’s ERC has been a part of this process since the early 1980’s.

Currently, constant feedback is needed to ensure the diamond will grow to their satisfaction. The primary objective of Team 4 is to provide information about the diamond surface as it is growing (i.e. in real time). We will implement a laser measurement system that will scan the top surface of the substrate and give slope information (angle/direction) at various points. Since growth rates are on the order of a few microns per hour, maintaining a high degree of accuracy as well as repeatable measurements is paramount. In addition, sample sizes ranging from 3mm x 3mm to 25mm by 25mm must be scanned in 200 seconds or less. In the future, this project will be implemented as a feedback subsystem for the chemical vapor deposition process

Techmark, Inc.: Fruit & Vegetable Damaged Detection Software

Techmark, Inc. is interested in designing an impact recording device (IRD) for measuring the bruising of fruits and vegetables that occurs while being processed from the farmer to the consumer. Techmark, Inc. currently has an IRD product in place that works with large fruits and vegetables like potatoes, tomatoes, apples, etc, but they would like a new IRD for smaller fruits and vegetables such as mushrooms, blueberries and strawberries. The goal of this project is to create a small IRD capable of measuring impacts for the smaller size fruits. Continuing of the project started in Fall 2016, our team will create an IRD that will meet all requirements from Techmark, Inc. With the new IRD, farmers will have an easier time detecting when and where the most bruising to their products occurs during the handling process.

Techmark, Inc. is interested in designing an impact recording device (IRD) for measuring the bruising of fruits and vegetables that occurs while being processed from the farmer to the consumer. Techmark, Inc. currently has an IRD product in place that works with large fruits and vegetables like potatoes, tomatoes, apples, etc, but they would like a new IRD for smaller fruits and vegetables such as mushrooms, blueberries and strawberries. The goal of this project is to create a small IRD capable of measuring impacts for the smaller size fruits. Continuing of the project started in Fall 2016, our team will create an IRD that will meet all requirements from Techmark, Inc. With the new IRD, farmers will have an easier time detecting when and where the most bruising to their products occurs during the handling process.

The IRD will have one 3V battery, a centralized accelerometer, a micro-USB port, and a 4-layer PCB to accommodate and perform as required. The sensor will last 3-4 hours and accumulate voltage drops and other useful information via the accelerometer. Once the sensor completes the process, the microcontroller will send the data to the PCIRD sponsor software for further action.

Team Members (L-R): Michael Karana, Lucas Bowman, Joe Simonetta, Valbona Vulaj, Alexander Budd, Rachel Ann Moses

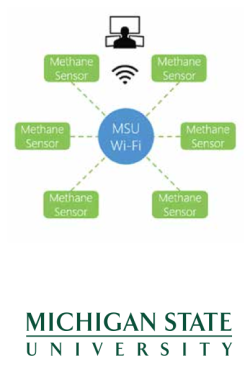

James Dyson Foundation/MSU: Distributed Natural Gas Detection System

Natural gas has positioned itself to become the primary fuel source for electricity generation in the United States. Originally designed for coal, MSU’s TB Simon Power Plant converted to 100% natural gas fuel to generate electricity and steam in 2016. This increased use of natural gas has made the detection of leaks a necessity for both safety and environmental reasons.

Natural gas has positioned itself to become the primary fuel source for electricity generation in the United States. Originally designed for coal, MSU’s TB Simon Power Plant converted to 100% natural gas fuel to generate electricity and steam in 2016. This increased use of natural gas has made the detection of leaks a necessity for both safety and environmental reasons.

The current sensors in use at MSU’s TB Simon Power Plant are less than ideal. The plant currently operates with two different sensors: handheld and hardwired. Handheld systems must be manually operated and are not ideal for use in hazardous areas. Hardwired solutions are very costly to implement and placement becomes the driving factor in its overall effectiveness.

The main objective of the project is to develop an array of low-cost wirelessly connected sensors that notify users when dangerous levels of natural gas are detected. The product will utilize preexisting Wi-Fi networks to ensure a completely mobile and adaptable detection system. The user will then be able to find the location of a leak with relative accuracy.

Our group will utilize an MQ4 methane sensor connected to a Raspberry Pi Zero microcontroller. The microcontroller will process the data gathered from the sensor and transmit it over Wi-Fi to the monitoring application

Michigan State University: Micro-Grid Control

MSU is currently constructing a 10 MW solar array in parking lots 83, 89, 91, 92 and 100. IPF (Infrastructure Planning and Facilities) is looking for a technical solution to increase the reliability of the micro-grid system and to reduce the total cost of utility operation. Our team is consulting with MSU in order to determine viable solutions that can provide stability when operating the solar array.

MSU is currently constructing a 10 MW solar array in parking lots 83, 89, 91, 92 and 100. IPF (Infrastructure Planning and Facilities) is looking for a technical solution to increase the reliability of the micro-grid system and to reduce the total cost of utility operation. Our team is consulting with MSU in order to determine viable solutions that can provide stability when operating the solar array.

Our team is developing solutions to reduce costs and power fluctuation in the solar array. We are also considering methods to predict cloud covering weather patterns.

In addition, we are developing solutions to implement external power sources such as batteries, capacitors, or hybrid energy systems in the solar array. We brainstormed multiple power systems and analyzed the pros, cons and cost- efficiency of each item. We then simulated electric and steam load shedding systems that would help conserve power across campus. As a side project, we are developing ways to predict coarse weather patterns either by using detection sensors or cloud image processing.

Daifuku/Jervis B. Webb Company: SmartCart Predictive Diagnostic Software

Jervis B. Webb, an industry leader in factory automation and material handling, has tasked our team with performing predictive maintenance on their SmartCart line of automated vehicles. With the ability to detect abnormality in subsystems before failure, downtime is minimized, as there is an opportunity to pull the SmartCart off the factory floor before progress is halted, increasing efficiency in productivity.

Jervis B. Webb, an industry leader in factory automation and material handling, has tasked our team with performing predictive maintenance on their SmartCart line of automated vehicles. With the ability to detect abnormality in subsystems before failure, downtime is minimized, as there is an opportunity to pull the SmartCart off the factory floor before progress is halted, increasing efficiency in productivity.

The deliverables to Jervis B. Webb include a set of general failure modes and an algorithm to detect these failure modes for any component. This way the software can be applied to any new component added. The goal is not to detect a specific failure for a specific component, rather to develop detection methods that can be applied to any component.

Also, there is a desire to integrate this software solution into Jervis B. Webb’s existing codebase. To facilitate this, a solution will be developed in C++ on a Linux Debian platform. A Raspberry Pi Model 3 B was chosen to be the platform for this software solution.

Team Members (L-R): Ryan Christiansen, Kenil Patel, Austin Brune, Brad Plec, Ryan Siegler, Yuhau Chen

Consumers Energy: AMI Smart Meter Data

Advanced Metering Infrastructure (AMI) technology allows for two-way communication between utility meters and their companies. Consumers Energy has begun to implement AMI smart meters across their market but currently lacks any meaningful analysis or visualization of the collected data and information. By analyzing and utilizing this data, Consumers hopes to better service customer demands. Consumers Energy has asked us to develop a tool to assist in data utilization as well as to simplify data visualization. They would particularly like to focus on the most important events, which may require immediate elicited response from Consumers.

Advanced Metering Infrastructure (AMI) technology allows for two-way communication between utility meters and their companies. Consumers Energy has begun to implement AMI smart meters across their market but currently lacks any meaningful analysis or visualization of the collected data and information. By analyzing and utilizing this data, Consumers hopes to better service customer demands. Consumers Energy has asked us to develop a tool to assist in data utilization as well as to simplify data visualization. They would particularly like to focus on the most important events, which may require immediate elicited response from Consumers.

Our team has chosen to focus on three types of events: power loss and outage, tampering and major voltage changes. For each event, we plan to create software that will simplify/ break down large datasets, analyze the event capture and flag the event occurrences of great significance. Flagged events are those that need attention, due to the possibility of theft or vandalism or repeated power outages. Our software will contain a simple graphical user interface (GUI) to display our results and use latitude and longitude data to place event occurrences onto a map. In addition, important flagged tampering events, those we consider very likely to be theft, are marked for review operations personnel by our GUI accessible function for easy access and rapid response.

Delphi: Low-cost Watchdog Controller

Delphi is currently developing advanced powertrain systems that are one-of-a-kind with few spare parts available. To protect these engines, Delphi has implemented a watchdog controller to shut down the engine in order to reduce damage to these prototype engines. The current controller is effective but expensive. Delphi is looking to develop a low-cost watchdog controller. The new controller will provide the same functionality as their current controller but reduce the cost of future builds.

Delphi is currently developing advanced powertrain systems that are one-of-a-kind with few spare parts available. To protect these engines, Delphi has implemented a watchdog controller to shut down the engine in order to reduce damage to these prototype engines. The current controller is effective but expensive. Delphi is looking to develop a low-cost watchdog controller. The new controller will provide the same functionality as their current controller but reduce the cost of future builds.

Our team will be developing a custom Printed Circuit Board using TI’s TMS320F28377SPZPQ 32-Bit microcontroller to meet the requirements specified by Delphi. A JTAG debugging port will be included in the design to facilitate flashing via Simulink. Implementing bulk converters will allow the watchdog to operate at a 9-16 V range. Other additional circuitry includes 2 CAN channels, 16 analog inputs and 12 analog outputs. Constructing an adapter harness enables the new watchdog to interface with the existing components. Our goal is to design a working watchdog controller that mimics the functionality of the existing controller within the budget of $500. Lowering the cost of the controller will allow Delphi to implement the prototype engines in more vehicle applications.

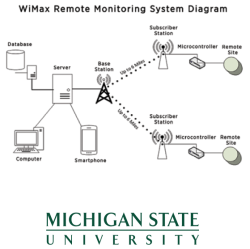

MSU EVPAS/IPS: WiMAX Communication System

Communication systems are essential for a variety of applications, ranging from small- scale video surveillance to large-scale utility monitoring systems. Michigan State University currently relies on fiber connections for adding new applications to the network. Laying fiber is both time-consuming and expensive because of the obstacles that the urban campus presents. Additionally, many of the applications do not require the throughput and bandwidth available through the fiber connections. Additionally, many wireless point-to-point connections currently on campus utilize Sub 1Ghz technology that only provide limited throughput for small applications.

Communication systems are essential for a variety of applications, ranging from small- scale video surveillance to large-scale utility monitoring systems. Michigan State University currently relies on fiber connections for adding new applications to the network. Laying fiber is both time-consuming and expensive because of the obstacles that the urban campus presents. Additionally, many of the applications do not require the throughput and bandwidth available through the fiber connections. Additionally, many wireless point-to-point connections currently on campus utilize Sub 1Ghz technology that only provide limited throughput for small applications.

MSU is interested in testing and exploring the potential of using a WiMAX communication system over campus. For a proof-of-concept, MSU is looking to set up a wireless connection between the sensors at the wells that supply water to MSU. The WiMAX 007 team has been tasked to research and set up a WiMAX network that would replace the current system for adding network applications. This wireless network would be a time-saving and cost-effective solution for the current system. Our team is also going to be laying the foundation for a larger WiMAX communication system that would work with other utility applications such as traffic intersection surveillance, parking lot surveillance, etc.

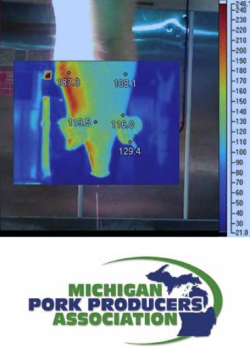

Michigan Pork Producers Association/MSU College of Veterinary Medicine & Large Animal Clinical Sciences: Pig O’Vision

The pork industry is faced with increasing regulations and laws relating to the safety and wellbeing of animals. MSU and the Michigan Pork Producers Association want to be on the forefront of modern technology to be prepared for those regulations when they are implemented in 2020. They desire a product that can gather data on pig size and weight without physical contact to make the process as simple and as safe as possible for both the animal and user. Using cameras and sensors, the system will take pictures, depth measurements, and thermal images to assess the health and biometrics as the pigs are moved from one location to another in the farm. With this data they hope to be able to raise a healthier and happier pig with less food and resources being wasted.

The pork industry is faced with increasing regulations and laws relating to the safety and wellbeing of animals. MSU and the Michigan Pork Producers Association want to be on the forefront of modern technology to be prepared for those regulations when they are implemented in 2020. They desire a product that can gather data on pig size and weight without physical contact to make the process as simple and as safe as possible for both the animal and user. Using cameras and sensors, the system will take pictures, depth measurements, and thermal images to assess the health and biometrics as the pigs are moved from one location to another in the farm. With this data they hope to be able to raise a healthier and happier pig with less food and resources being wasted.

Our team understands the needs and requirements of the industry and is designing a system that will benefit not only the producers and researchers, but also the consumer. The pork industry, with the help of the system, will be able to raise animals in a more uniform process that also relies on individual needs of each animal as they grow. By lowering the price of raising a pig, the industry can pass the saving onto the consumer with lower and more consistent pricing.

Team Members (L-R): Jack Adams, Srikar Bollavaram, Yan Zhou, Wu Zhaoqi, Casey Benjamin, Peng Ni, Minghao Zha

ArcelorMittal: Optical Verification of Steel Coil Rail Car Loads

ArcelorMittal is one of the largest steel companies in the world, producing over 100 million tons of steel every day. With steel prices expected to rise in the upcoming years, it is vital for each coil of steel to be accounted for. Also, to remain competitive in the steel industry, all processing and shipping times must be made as efficiently and quickly as possible.

A record is created for every rail car that leaves ArcelorMittal. It keeps track of which steel coils are loaded onto a given railcar. This data must be compared to what is actually in the rail cars that are ready to be shipped out. Currently, a technician is tasked with reading each railcar ID, then checking that each steel coil is in the correct rail car. This process slows down shipping time and is vulnerable to errors by the technician. ArcelorMittal does have technology that can scan a barcode on a steel coil. A way to quickly identify the railcar would able to further improve their shipping process.

record is created for every rail car that leaves ArcelorMittal. It keeps track of which steel coils are loaded onto a given railcar. This data must be compared to what is actually in the rail cars that are ready to be shipped out. Currently, a technician is tasked with reading each railcar ID, then checking that each steel coil is in the correct rail car. This process slows down shipping time and is vulnerable to errors by the technician. ArcelorMittal does have technology that can scan a barcode on a steel coil. A way to quickly identify the railcar would able to further improve their shipping process.

Our team is designing a system to improve the accuracy and efficiency in the steel coil verification process. To solve the issue of railcar recognition, an Optical Character Recognition, or OCR, software would be implemented into the design. For mobility within the ArcelorMittal plant, the software will be programmed into a rugged industrial tablet. The tablet will be able to identify the railcar ID number with just a photo; then the steel coils within the railcar can have their barcodes scanned. This recorded data will be checked together with the data of what the railcar is intended to have in it. If all of the steel coils are in the right car, the technician will receive an immediate confirmation from the tablet and can then proceed to the next car. The new process will greatly reduce the time it takes to verify the location of the steel coils, and well as reduce possible errors in manually reading the ID numbers.

Michigan State University: Simulation Software for Crack Detection in Materials

Cracks in structures such as airplanes can propagate and lead to catastrophic failures – it is critical to detect cracks in early stages. A commonly used approach to detect and size cracks is based on the relation between the crack size and the local electrical resistance of materials. When a voltage is applied across a material with a crack present the current density through that material will be higher around the crack, which is the current crowding effect. It will result in the constriction resistance which increases the total resistance of the material. In this project we will demonstrate how to evaluate cracks in a samples, by simulating the current crowding and constriction resistance for a variety of crack geometry using COMSOL.

Cracks in structures such as airplanes can propagate and lead to catastrophic failures – it is critical to detect cracks in early stages. A commonly used approach to detect and size cracks is based on the relation between the crack size and the local electrical resistance of materials. When a voltage is applied across a material with a crack present the current density through that material will be higher around the crack, which is the current crowding effect. It will result in the constriction resistance which increases the total resistance of the material. In this project we will demonstrate how to evaluate cracks in a samples, by simulating the current crowding and constriction resistance for a variety of crack geometry using COMSOL.

We first use theoretical formulas given in Dr. Peng Zhang’s paper, “On the Spreading Resistance of Thin-Film Contacts,” IEEE Trans. Electron Devices, 59, 1936 (2012), [1] to solve for the resistance of a sample material. We then validate the model by simulating current conduction in the same geometry using the AC/ DC module in COMSOL and comparing with theoretical results. The validated model can then be used to predict the resistance due to different crack geometry. These results can be used to find the correlation between the electrical resistance and the crack size and geometry. The results will be very useful to prevent failure of critical structures.