Electrical Engineering

Projects

Electrical and Computer Engineering ECE 480 Senior Design is required of all electrical and computer engineering majors at MSU.

For information on becoming a project sponsor, please contact Gregg Motter.

The following were the project sponsors and projects for Fall 2016:

Great Lakes Controls & Engineering, LLC Panther Global Technologies: Orthopedic Exercise Feedback

Great Lakes Controls and Engineering, LLC, partnered with Panther Global Technologies, is interested in developing a shoulder exercise feedback system to add onto an existing therapy machine. They are looking for a reliable system to track patients’ therapeutic progress as well as to ensure that exercises are performed correctly. The purpose is to implement this in everyday therapy to ensure superior results in comparison to today’s methods.

The control system will consist of a number of components. A servo unit will be implemented to control the fly weight, enabling the weight resistance of the exercise to be modified. Meanwhile, an encoder will be used to communicate to the system the distance by which the machine has moved. To ensure the exercise is performed correctly, a brake solenoid will enable or disable movement of the machine depending on requirements. Also, proximity sensors will determine whether or not full movement has occurred.

The control system will consist of a number of components. A servo unit will be implemented to control the fly weight, enabling the weight resistance of the exercise to be modified. Meanwhile, an encoder will be used to communicate to the system the distance by which the machine has moved. To ensure the exercise is performed correctly, a brake solenoid will enable or disable movement of the machine depending on requirements. Also, proximity sensors will determine whether or not full movement has occurred.

Through a secure website, the therapists will be able to prescribe custom therapy routines and upload them to a database. The patient will have an interactive touchscreen application attached to the machine to log into his or her secure account. After logging in, he or she will be prompted to complete the customized, prescribed routines. Upon completion, the record will be sent back to the patient’s therapist, who can retrieve the information via the same secure website.

Successful completion of project goals will result in a functioning control system to ensure correct exercise operation, and provide continuous feedback.

MSU Office of the Executive Vice President: Smart Parking Lots

Parking on MSU’s campus is limited. Drivers often circle from lot to lot looking for spaces. Some faculty and staff are reluctant to leave campus during peak hours (lunch time) or to go to meetings for fear of losing their parking space.

MSU is interested in developing a smart parking solution that would provide real-time information on the number of spots available in each parking lot. This would allow drivers to target lots with open spaces and make other more informed choices about their commute on campus. Currently, there is a potential path for Smart Parking on campus in gated lots; however, it will involve a costly replacement of gate arms across campus. We wish to develop a lower cost solution that might accelerate the pace of deployment of a new parking system on campus and are interested in the students’ views and ideas to address this problem.

MSU is interested in developing a smart parking solution that would provide real-time information on the number of spots available in each parking lot. This would allow drivers to target lots with open spaces and make other more informed choices about their commute on campus. Currently, there is a potential path for Smart Parking on campus in gated lots; however, it will involve a costly replacement of gate arms across campus. We wish to develop a lower cost solution that might accelerate the pace of deployment of a new parking system on campus and are interested in the students’ views and ideas to address this problem.

Our team recognizes the struggle of finding an available parking spot on campus, especially during peak hours. We are committed to solving the problem of uncertainty through sensing technology and networking in order to inform drivers of the capacity in real-time. This will allow a driver to make an informed decision when targeting a parking lot, eliminating time wasted in searching for space.

ArcelorMittal: Safety Equipment for Barcode Scanner

ArcelorMittal is a Luxembourg-based multinational steel manufacturing corporation headquartered in Avenue de la Liberté, Luxembourg. It was formed in 2006 from the takeover and merger of Arcelor by Mittal Steel. ArcelorMittal is the world’s largest steel producer, with an annual crude steel production of 98.1 million tons as of 2014. At such a high volume of manufacturing, regulations require ArcelorMittal to provide their employees access to a wide variety of safety equipment.

Current safety devices such as fire extinguishers and AEDs require periodic inspections which must be documented. In most instances, these inspections are documented at the location of the device on a paper record or attached tag. If that record is lost, so is the history of the inspections. Also, in many cases, there is no method to confirm that all required devices have been inspected as prescribed. Additionally, inspections such as these are often targets of audits. Auditors visit the locations of these devices to confirm inspections occur as scheduled; these audits could be more efficient if records were available electronically. Lastly, electronic confirmation of these inspections will alert responsible personnel of inspection failures.

Current safety devices such as fire extinguishers and AEDs require periodic inspections which must be documented. In most instances, these inspections are documented at the location of the device on a paper record or attached tag. If that record is lost, so is the history of the inspections. Also, in many cases, there is no method to confirm that all required devices have been inspected as prescribed. Additionally, inspections such as these are often targets of audits. Auditors visit the locations of these devices to confirm inspections occur as scheduled; these audits could be more efficient if records were available electronically. Lastly, electronic confirmation of these inspections will alert responsible personnel of inspection failures.

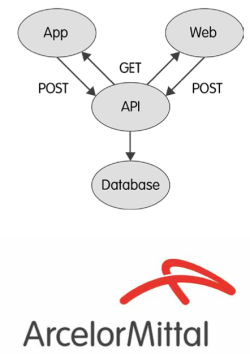

Our team has developed an ecosystem in order to automate this process for ArcelorMittal. As a team, we accomplished our objectives by creating a mobile application to scan barcodes, and a responsive admin website to maintain and audit data. The mobile application uses open source barcode scanning libraries, and the website takes advantage of existing industry standard frameworks and communication protocols.

The database is developed using the standard SQL interface which allows easy integration with any enterprise database software. Overall this system was designed with the user at the forefront, constructing an environment that is easy for anyone to use.

Techmark, Inc.: Impact Recording Device (IRD)

Techmark was founded in 1987 in Lansing, Michigan to provide advanced technology solutions to assist agriculture producers and companies around the world. Today the Techmark Impact Recording Device (IRD) is the world’s leading tri-axial impact recorder.

A 2013 study by Stellenbosch University suggested that up to 40% of produce may be affected by bruising. Produce that is bruised not only has a shorter shelf life, but also higher chance of disease in storage and lower overall quality. The IRD manufactured by Techmark offers an opportunity to monitor moments in harvesting and shipping where most bruising occurs.

A 2013 study by Stellenbosch University suggested that up to 40% of produce may be affected by bruising. Produce that is bruised not only has a shorter shelf life, but also higher chance of disease in storage and lower overall quality. The IRD manufactured by Techmark offers an opportunity to monitor moments in harvesting and shipping where most bruising occurs.

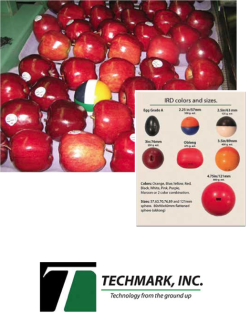

The picture on the right depicts all of the IRD models Techmark presently provides. The design of the IRD limits the ability to make the IRD smaller than 2.25” in diameter. This currently works well for a wide range of fruits and vegetables such as apples and potatoes. However, this circuit design is simply too large to replicate smaller produce such as blueberries, strawberries, and tree nuts.

The goal of this project is to redesign the interior circuitry of the IRD to be 1” in diameter to accommodate the smaller produce. All circuitry components of the IRD will need to be changed and redesigned to fit the desired size limitations. The main components that the team will need to research and implement are a smaller microcontroller, accelerometer, and battery pack. Even though the circuit components will be very small, they still need to be durable and long-lasting.

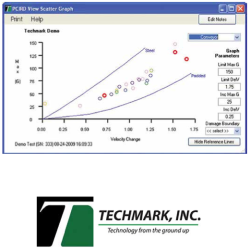

Techmark, Inc.: Fruit & Vegetable Damaged Detection Software

Techmark is a multinational agricultural technology company that provides advanced technology solutions to progressive agricultural producers and companies. Techmark produces impact recording devices that collect information on vegetables and fruit.

The Impact Recording Device (IRD) is stored with agricultural products in warehouses or trucks and records the force of impact and velocity change.

The Impact Recording Device (IRD) is stored with agricultural products in warehouses or trucks and records the force of impact and velocity change.

Since the IRD is placed with agricultural products during recording impact, the size of the IRD should be same as that of the product in order to ensure that the impact on the IRD is the same as that on the product. The current version of IRD is only able to test the impact on potatoes. In other words, the size of the IRD is related to the scale of product market. To expand the market of IRD, our team is working on developing a smaller IRD.

To reduce the size of the IRD, we built an adapter which contains a microcontroller and a charger. With this adapter, we were able to choose a smaller microcontroller in the IRD since the functions needed can be coded in the adapter.

The new design of product reduces the size of the IRD into less than one inch and enables it to work for small fruit, for example strawberries. In addition, the separate control on the adaptor simplifies updating a new generation of IRDs.

Whirlpool Corporation:Washer/Dryer Diagnostic Smartphone Application

Whirlpool is a renowned international appliance manufacturer, producing high quality products for homeowner and tenant communities around the world. Whirlpool wants to improve the responsiveness of its customer service by linking technicians with any technical demand in near real-time. Our team has been given the opportunity to develop a smartphone app that can automate the instruction manual experience or, if the customer prefers, provide direct information to a Whirlpool technician.

We have developed a camera-based method of communication between Whirlpool machines and smartphones. The overall objective is the creation of a smartphone application that can read and decipher error codes straight from a Whirlpool machine. By improving the customer service experience, this application provides a great amount of practical benefit for both the consumer and Whirlpool.

We have developed a camera-based method of communication between Whirlpool machines and smartphones. The overall objective is the creation of a smartphone application that can read and decipher error codes straight from a Whirlpool machine. By improving the customer service experience, this application provides a great amount of practical benefit for both the consumer and Whirlpool.

Most of Whirlpool’s appliances are designed to have minimal user interfaces, typically consisting of a set of LEDs that display the status of the appliance. These LEDs are the main method of communication between the machine and the user and also between the appliance and a technician via a set of error codes. Our team improves upon the current one-on-one communication approach by designing a smartphone app and a communication protocol that sends error code information directly to the company and the user. In the successful prototype that uses a simulated LED matrix, the LEDs are blinking at a specified frequency visible to a smartphone camera. The app deciphers the LED error code sequence and sends the data to Whirlpool while simultaneously generating a user readable output. The user is then offered the option of scheduling a technician appointment at his/ her convenience and both are well informed.

MSU Resource Center for Persons with Disabilities: Prosthetic Arm Control System

The Resource Center for Persons with Disabilities at Michigan State University is dedicated to providing assistance and advocacy for MSU students with disabilities. In the past few months, a MSU student and congenital amputee, Lee Cleaveland, has approached RCPD with a proposal for developing a lower-arm myoelectric prosthesis for his daily use. A component of the design of this arm has become the task of our Design Team.

Prior to contacting RCPD, Lee had researched custom bionic arms, but found these devices cost thousands of dollars and would not meet his needs. Lee began looking into other options and contacted RCPD for support who, in turn, contacted the ECE department with a proposal for a control system for a custom prosthetic designed by RCPD.

Prior to contacting RCPD, Lee had researched custom bionic arms, but found these devices cost thousands of dollars and would not meet his needs. Lee began looking into other options and contacted RCPD for support who, in turn, contacted the ECE department with a proposal for a control system for a custom prosthetic designed by RCPD.

The team will begin by building a prototype arm with one degree of motion using 3D printing technology and low-cost consumer electronics. Each finger will be driven by a servo, which will be driven from motor drivers. A real-time processor will serve as the core of the arm, translating sensor input signals into signals to control the motor drivers.

The goal of the design team is to construct the control system of a functional prosthetic arm as part of a complete, collaboratively-designed prosthetic. The control system will meet Lee’s daily requirements, as outlined in the initial meeting, such as different hand positions, lifting, and grasping.

TI, MSU RCPD and MSU Demmer Center: Precision Pointing Device for the Blind

The MSU Demmer Center is a shooting sports training facility that has both indoor and outdoor archery ranges, as well as indoor firearm ranges, where visitors can shoot up to .22 caliber pistols and rifles. In addition, the center offers Paralympic sport outreach for various activities including training blind individuals. The MSU Resource Center for Persons with Disabilities (RCPD) has reached out to the engineering program to develop a device to aid blind individuals in participating in recreational activities at the center, including archery and small caliber target practice.

The current model was created by a group of ECE 480 students in the spring of 2016. This was developed with haptic feedback utilizing machine vision to determine distance from target. Through use of a Raspberry pi 2 and OpenCV, the system is able to vibrate motors in a wrist strap to allow the user to better aim their device.

The current model was created by a group of ECE 480 students in the spring of 2016. This was developed with haptic feedback utilizing machine vision to determine distance from target. Through use of a Raspberry pi 2 and OpenCV, the system is able to vibrate motors in a wrist strap to allow the user to better aim their device.

The goal for this semester is to build on the system developed by the previous team and create an appealing and easy-to-use product. In order to accomplish this task, wireless haptic and audio feedback will be implemented. Software improvements will allow for easier and more functional use. Sensor enhancements will include wind speed, wind direction, and distance sensors that will allow the user to point at the target’s bullseye.

General Motors: Electric Car Noise System

By the year 2018, the NHTSA will require all automakers in the United States to comply with minimum sound requirements for hybrid and electric vehicles. This legislation is a result of the danger posed to pedestrians due to the lack of noise produced by moving hybrid and electric cars. The law states that a hybrid electric vehicle must emit a sound that resembles that of an internal combustion engine at a certain decibel level that can be heard by nearby pedestrians.

General Motors has responded to this legislation by implementing a basic speaker to emit sound from their electric vehicles, such as the Chevy Volt and Spark. The problem is that these current systems do not meet the level of innovation that General Motors desires. The sound emitted from these devices is not directional and is penetrating into the passenger area of the vehicle, thus compromising the expected quiet and comfort of the driver’s experience. In addition, the loudspeakers currently used do not effectively deliver sound to nearby pedestrians.

General Motors has responded to this legislation by implementing a basic speaker to emit sound from their electric vehicles, such as the Chevy Volt and Spark. The problem is that these current systems do not meet the level of innovation that General Motors desires. The sound emitted from these devices is not directional and is penetrating into the passenger area of the vehicle, thus compromising the expected quiet and comfort of the driver’s experience. In addition, the loudspeakers currently used do not effectively deliver sound to nearby pedestrians.

General Motors has asked our team to develop a new kind of sound-emitting device that tackles these issues. The team has developed a piezoelectric speaker array that can be placed on the fascia of the vehicle. The speakers emit a frequency modulated ultrasonic tone consisting of an audio signal and a carrier signal. When these soundwaves hit an object, the signals mix and deconstruct into an audio-band signal that can be heard. The advantages are: piezoelectric speakers are much more directional than traditional loudspeakers, and the ultrasonic frequencies are easily damped by passive noise reduction techniques in GM vehicles.

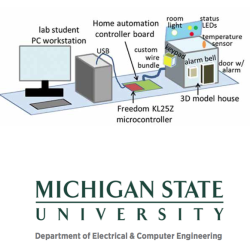

MSU Dept. of Electrical & Computer Engineering: Home Automation Educational Platform

The MSU Department of Electrical and Computer Engineering has offered the opportunity to develop an educational platform utilizing a home automation model. Our challenge is to create a standalone, closed-loop, fully functional model home that will facilitate students’ learning of analog-to- digital conversion in embedded systems labs. They require the controller board to use the Freedom KL25Z microcontroller, currently used in labs, to provide a relatively seamless transition in learning.

The model home must be as true to life as possible using sensors, actuators, and other components that would typically be found in the home. Required components include at least two sensors, two actuators, necessary analog interfaces, the KL25Z microcontroller, 110VAC lighting, and a USB PC interface to provide status updates or alerts via email and/or text message. The model home will house all the required sensors and actuators, and provide a user interface to arm and disarm the system with user feedback via status LEDs.

The model home must be as true to life as possible using sensors, actuators, and other components that would typically be found in the home. Required components include at least two sensors, two actuators, necessary analog interfaces, the KL25Z microcontroller, 110VAC lighting, and a USB PC interface to provide status updates or alerts via email and/or text message. The model home will house all the required sensors and actuators, and provide a user interface to arm and disarm the system with user feedback via status LEDs.

The controller board will provide all necessary power supplies, transformers, and an optional battery backup power supply. Test algorithms pre-programmed on the KL25Z microcontroller will demonstrate all the functionality of the model home. Programming and interfaces are designed such that sensors, actuators, and the programing itself can easily be added, removed, or modified to provide a variety of learning modes.

Team Members (L-R): Ziwen Zhang, David Powers, Bryan Essenmacher, Joseph Thom, Sean Irwin, Evan Jakovac

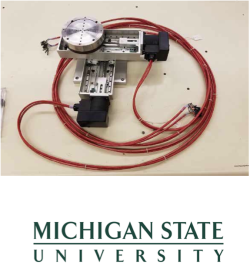

Michigan State University: Maskless Lithography System

Michigan State University is interested in developing a maskless lithography system. They have tasked our team with developing a production unit to be used for research and teaching. The ECE Cleanroom presently has a standard mask aligner. With a maskless lithography system, students could have the flexibility of changing the lithography patterns rapidly without the added costs associated with purchasing additional masks.

The main objective of this project was to create a system that takes CAD and Bitmap files and engraves silicon on a rotation stage. The rotation stage can move in the X-Y-Z direction and can vary dynamically through software. The system will be able to print on a 4×4 inch wafer and has a beam width of less than 50 microns.

The main objective of this project was to create a system that takes CAD and Bitmap files and engraves silicon on a rotation stage. The rotation stage can move in the X-Y-Z direction and can vary dynamically through software. The system will be able to print on a 4×4 inch wafer and has a beam width of less than 50 microns.

The system connections are housed within an aluminum enclosure. It is controlled by the user through a MACH 4 interface that interacts with the rotation stage and UV light. The microcontroller also handles all the computation of the UV light in order to manage intensity and duration. Successful completion of the project will result in a lithography system that is able to engrave CAD images on a silicon wafer.

NeEWS Lab:A Solar Powered Network of Internet of Things

The Networked Embedded & Wireless Systems Laboratory (NeEWS) at Michigan State University focuses on finding solutions to upcoming communication problems that will greatly affect the world. With Industry 4.0 becoming ever more prevalent, taking measurements of something in the field is becoming increasingly more expensive due to the amount of work necessary to connect sensors to stationary power sources. The NeEWS Lab needs an expandable hardware platform that can be controlled and utilized remotely, using only energy harvested from sunlight. This platform will provide a solution to the problem and enable wireless sensing using only sunlight.

A customized hardware platform that can be upgraded and expanded will be developed, as well as accompanying software that will connect all of the platforms together to perform measurements in the most energy efficient manner. The energy efficiency will be achieved through implementing a novel SDN for IoT networking protocol that minimizes energy consumption while allowing continuous sensing.

A customized hardware platform that can be upgraded and expanded will be developed, as well as accompanying software that will connect all of the platforms together to perform measurements in the most energy efficient manner. The energy efficiency will be achieved through implementing a novel SDN for IoT networking protocol that minimizes energy consumption while allowing continuous sensing.

A working system would consist of a base station and as many nodes as are necessary to perform all of the sought- after measurements. Bringing more nodes into the system and moving them from location to location will be seamless. The networking stack solution that will arise from this research will be useable as a framework upon which other future Internet of Things applications can be built and foster further innovations in this growing field.