Electrical Engineering

Projects

Electrical and Computer Engineering ECE 480 Senior Design is required of all electrical and computer engineering majors at MSU.

For information on becoming a project sponsor, please contact Gregg Motter.

The following were the project sponsors and projects for Fall 2015:

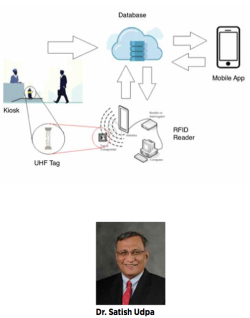

Dr. Satish Udpa: RFID Luggage Tagging and Tracking

The current luggage tracking system, centered around barcode reading, is prone to failure as evidenced by the 15% failed scan percentage. These failed scans result in significant damages to airlines both in reputation and in monetary deficits in the form of customer compensation and manual labor costs. The Sponsor for Design Team 1, Dr. Satish Udpa, has proposed a new system for scanning, revolving around the use of Radio Frequency Identification (RFID) technologies.

The current luggage tracking system, centered around barcode reading, is prone to failure as evidenced by the 15% failed scan percentage. These failed scans result in significant damages to airlines both in reputation and in monetary deficits in the form of customer compensation and manual labor costs. The Sponsor for Design Team 1, Dr. Satish Udpa, has proposed a new system for scanning, revolving around the use of Radio Frequency Identification (RFID) technologies.

RFID is becoming increasingly popular in a variety of fields including access security, commercial shipping, and anti-theft systems. Because of the recent increase in RFID usage, production has increased to the point where the cost associated with the components has decreased to practical levels, making more industries interested in integrating these technologies into existing systems.

The team’s airport RFID reader is capable of scanning a single tag from up to five meters away and multiple tags over smaller distances. After scanning a tag, the reader adds the encoded information to a database from which an airline or customer can retrieve information pertaining to a specific bag. The mobile reader can identify a traveler’s luggage from within a foot by comparing the scanned tag with the user’s information in the database. By seamlessly reading this information from a tag, the location and status of a piece of luggage may be more easily processed and tracked.

Ultimately this technology will revolutionize automation in the commercial industry due to its passive nature, near perfect read success rate, and low costs. The team is excited to see the future of RFID technology.

Fraunhofer Center for Coatings and Diamond Technologies: Monitoring of Diamond Polishing Process

Diamond polishing begins by gluing a diamond onto the bottom of an assembly arm which then is held against a high-speed, rotating wheel, coated with diamond powder. The diamond is held against the cast iron wheel and is polished. While the diamond scrapes against the wheel it emits a “sound.” These sounds are frequencies which vary depending on the balance of the arm and wheel as well the surface and shape of the diamond. Currently, other than listening with your own ear, the diamond polishing lab has no way of indicating how smoothly the polishing is going. In order to monitor this difference in sound, a device will be created that will send real-time data to the operator so they can monitor the current polishing. This data will also facilitate future experiments.

Diamond polishing begins by gluing a diamond onto the bottom of an assembly arm which then is held against a high-speed, rotating wheel, coated with diamond powder. The diamond is held against the cast iron wheel and is polished. While the diamond scrapes against the wheel it emits a “sound.” These sounds are frequencies which vary depending on the balance of the arm and wheel as well the surface and shape of the diamond. Currently, other than listening with your own ear, the diamond polishing lab has no way of indicating how smoothly the polishing is going. In order to monitor this difference in sound, a device will be created that will send real-time data to the operator so they can monitor the current polishing. This data will also facilitate future experiments.

The design relies on a two-microphone system which will collect the frequencies emitted from the wheel and the diamond. The frequencies emitted from the wheel will be filtered using a band-pass filter, and the frequencies emitted from the diamond will be filtered using a high-pass filter. Both of these frequencies will be shown on a display as well as sent to the operator’s computer by microcontroller.

Additionally, to monitor the balance of the arm, an accelerometer will be used and connected to an alarm so the operator will know when the arm balance needs to be fixed.

Great Lakes Controls & Engineering: Incoming Power Grid Monitoring

Great Lakes Controls & Engineering was recently contracted with the task of developing a power monitoring system that will be applied in factories that use 3 phase power. 3-phase power could possess voltage imbalance and poor power factor. Voltage imbalances damage delicate machinery which could be expensive to repair or replace. Poor power factors result in additional charges from power utilities.

Great Lakes Controls & Engineering was recently contracted with the task of developing a power monitoring system that will be applied in factories that use 3 phase power. 3-phase power could possess voltage imbalance and poor power factor. Voltage imbalances damage delicate machinery which could be expensive to repair or replace. Poor power factors result in additional charges from power utilities.

Great Lakes Controls & Engineering experimented with the EXTECH 3-Phase Power Analyzer/Datalogger as a way to monitor the problem. Although the device possesses many functions for power monitoring, it lacks the ability to send notifications upon the detection of a voltage imbalance and log large amounts of data. Team 3 was tasked with developing a device which would replicate the functions of the EXTECH device and possess additional features to make up for its shortcomings.

To meet the requirements set forth by our sponsor, we designed a device that will sense an analog power signal and log the data into the device’s internal memory, simultaneously comparing the logged data with the set voltage and current tolerances. If the data are above the tolerance, a notification email will be sent with a time stamp of when the event occurred. The device will be equipped with three additional features: a capacitor bank control circuit that will switch on if the detected power factor is below the set tolerance, a backup battery that will be switched on upon the loss of power, and the ability to export the logged data wirelessly.

St. Mary Star of the Sea: IV Assistant Robot

St. Mary Star of the Sea Church is a Catholic parish church built in 1926 – almost 90 years ago – in Jackson, Michigan. The church is home to countless historic treasures, including a 125-year-old Roosevelt pipe organ designed and built by the cousin of President Franklin Roosevelt. By installing a video monitoring system, this nearly century old facility will be enhanced with 21st century capabilities.

St. Mary Star of the Sea Church is a Catholic parish church built in 1926 – almost 90 years ago – in Jackson, Michigan. The church is home to countless historic treasures, including a 125-year-old Roosevelt pipe organ designed and built by the cousin of President Franklin Roosevelt. By installing a video monitoring system, this nearly century old facility will be enhanced with 21st century capabilities.

This project has the ability to positively impact the entire St. Mary community, especially the parents of young children. Currently, if children act out or start crying during the service, parents have only two options: 1) keep attending the service at the cost of their child disturbing other participants, or 2) leave the service to relocate to the church’s ‘crying room.’ Neither option is desirable. Implementation of this system will make it possible for parents to participate remotely. A wireless camera will transmit a live video feed to a TV in the ‘crying room,’ so parents do not miss out on the speaker’s message.

The same system can also be used to monitor the church for unwanted intrusions. The camera will be left on 24/7 to provide surveillance. Video will be recorded onto a computer to play back footage as necessary.

Pictured on the right is a basic concept of the system: video from the camera is sent to the computer, the computer outputs video for live streaming and saves video onto a hard drive, and the HDMI receiver displays feed on a monitor.

ArcelorMittal: Cone of Safety around Crane Hook

ArcelorMittal needs a reliable and robust way to measure large coils of cold-rolled steel coming off their production line. The proposed solution is to use the Axis Communications P1355-E Camera to capture live high quality video of the steel as it is being coiled at the end of ArcelorMittal’s line. A dedicated computer will process the image produced by the Axis camera. This computer will be connected to the Axis camera and current system using Ethernet cables.

ArcelorMittal needs a reliable and robust way to measure large coils of cold-rolled steel coming off their production line. The proposed solution is to use the Axis Communications P1355-E Camera to capture live high quality video of the steel as it is being coiled at the end of ArcelorMittal’s line. A dedicated computer will process the image produced by the Axis camera. This computer will be connected to the Axis camera and current system using Ethernet cables.

ArcelorMittal is the world’s leading steel and mining company with presence in 60 countries and has an industrial footprint in 19 countries. ArcelorMittal is guided by a philosophy to produce safe and sustainable steel. ArcelorMittal prides itself in providing a safe work environment for its employees. To further their commitment to safety, ArcelorMittal is proud to be a sponsor of a Capstone Project at Michigan State University.

ArcelorMittal’s commitment to advancing safety throughout their East Chicago, Indiana facility can be, in part, accomplished by implementing a cone of safety on remote control overhead cranes. Overhead cranes carry steel coil loads back and forth throughout the Finishing Department. The project description includes invoking a system that will create a cone around the steel coils that will sound an alarm if the crane operator enters the cone. The system will turn on at a predetermined height and the radius of the cone will change as the crane moves up and down.

The designed system will consist of two major components. One component is a sensing system to know when an operator breaches the cone. The height of the load will be sensed by a proximity sensor and activate a thermal sensor of a programmed radius that changes when the height changes. The second component is an alarm system that will sound an alarm and record alarm data when an operator is sensed by the thermal sensor’s cone. The recorded alarm data will allow ArcelorMittal to effectively create procedures to better protect crane operators.

TRIFECTA: Classroom Noise Monitor

The Trifecta initiative is an intercollegiate effort between the Michigan State University Colleges of Engineering, Communication Arts and Sciences, and Nursing. Their goal is to advance the delivery of health services for diverse communities around the world.

The Trifecta initiative is an intercollegiate effort between the Michigan State University Colleges of Engineering, Communication Arts and Sciences, and Nursing. Their goal is to advance the delivery of health services for diverse communities around the world.

Classroom noise is a frequent problem in elementary schools. Teachers need to talk louder to be heard over the children, which often results in missed work due to vocal strain and in some cases voice disorders. Research in classroom noise acoustics suggests that there should be at least a 6-decibel difference between the teacher’s voice and the background noise in order for students to comprehend what the teacher is saying.

The children need to learn to lower their voices during class. The device proposed would measure the noise of the children and the noise of the teacher. Using spectral subtraction, the teacher’s voice signal is removed from the background noise monitor. Then, the two dBa levels are compared and, if they are too close, a lighting system will activate. This lighting system will activate based on noise level. Using the three colors of a traffic light, the children will be informed of how loud they are being. The children will then be able to correct their own behavior, and classroom noise will decrease.

Over time, teachers will need to strain their voices less, and will miss less time at work. If implemented when students are young, this behavior modification will have a positive effect as they enter higher levels of schooling.

Michigan State University: Early Warning Sensing for Solar Panels

Michigan State University, in an effort to use renewable energy, is in the process of acquiring a solar panel array. The solar panels will be located in the southern section of Michigan State’s campus and will cover five large parking lots via carport structures. Solar energy electricity output depends on the amount of light shining at any particular time. Since the electricity output depends upon the current weather a sudden change in cloud cover will create a reduction in the solar panel power output and create costs to import backup power go up greatly.

Michigan State University, in an effort to use renewable energy, is in the process of acquiring a solar panel array. The solar panels will be located in the southern section of Michigan State’s campus and will cover five large parking lots via carport structures. Solar energy electricity output depends on the amount of light shining at any particular time. Since the electricity output depends upon the current weather a sudden change in cloud cover will create a reduction in the solar panel power output and create costs to import backup power go up greatly.

Our team is developing an early warning system based on remote sensors, which will enable users to anticipate changes in the output of the solar array and take appropriate action in the local profile.

By placing sensors a designated distance outside the solar panel array, a time series of the amount of light can be taken and relayed wirelessly to the control station. A software program takes the data and creates a real-time simulation of the weather around the solar panel array. Using real-time simulation, an early warning can alert users to changing weather conditions.

A sensor and microcontroller will be placed on residential homes around the area. At these locations the sensor data can be uploaded to the residential owners’ Wi- Fi and to a server accessible for the software platform.

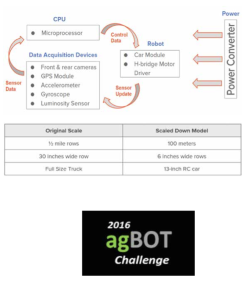

MSU Department of Electrical Engineering: agBOT Challenge

AgBOT stands for Agriculture Robot which is capable of performing farming processes like seeding and spreading fertilizer with minimum human intervention.

AgBOT stands for Agriculture Robot which is capable of performing farming processes like seeding and spreading fertilizer with minimum human intervention.

The agBOT Challenge is to create an agricultural robot that has the capability of planting two types of seeds and applying liquid fertilizer on top for 12 half- mile long rows. The entire process should be done autonomously.

The agBOT should exchange data, such as the speed of the robot, seeding speed and the position of the robot. The agBOT also needs to have front and rear cameras that can provide live video feed.

Due to time and budget constraints, a complete agBOT could not be built. Therefore, our project was to build a scaled-down model of a real agBOT and focus mainly on the electronics of the agBOT.

The electronics includes driving in autonomous mode based on GPS, and communications which includes transferring data and live video feed.

We have used Raspberry PI with GPS and Gyroscope module to operate the car. Wi-Fi was used for communication purposes. We also have three sensors collecting passive data that do not affect any driving process.

A control loop between Raspberry PI and GPS is responsible for the autonomous driving. Moreover, there are connections for expanding passive sensor modules for future upgrades.

MSU Resource Center for Persons with Disabilities: E-Bike Motor and Controller

In a novel entrepreneurial enterprise, Dr. Pauliah and his sister Ms. Pauliah of the Sunrise Orphanage in Bobbili, India, are seeking a product that can be manufactured and sold to help support the orphanage and add a low-cost medical clinic to the existing facility.

In a novel entrepreneurial enterprise, Dr. Pauliah and his sister Ms. Pauliah of the Sunrise Orphanage in Bobbili, India, are seeking a product that can be manufactured and sold to help support the orphanage and add a low-cost medical clinic to the existing facility.

Michigan State University is affiliated with the Sunrise Orphanage and its future clinic through Asian Aid USA, a Christian nonprofit organization that is committed to making a difference in the lives of children and people in poverty.

Asian Aid High School students in Jaipur, India learn electronic circuit design from Stephen Blosser, an Assistive Technology Specialist at the Resource Center for Persons with Disabilities. Mr. Blosser is an honorary ambassador volunteer with orphanages in the area and helps choose technology for the orphanage members to work with. He has designed an electric tricycle, which is in high demand in India and around the world.

Team 9 is designing a motor controller for a low-cost, high- independence, and rugged electric vehicle. Typically, they are powered through the use of a costly DC motor.

To combat this problem, ECE 480 Team 9 is using an inexpensive automotive alternator that replaces the DC motor, providing higher efficiency and increased torque at wider ranges of speed.

Whirlpool Corporation: Wireless Sensor Unit for Dryers

Selling more than 20 billion dollars’ worth of home appliances to over 170 countries, Whirlpool Corporation is an American multinational manufacturer and a Fortune 500 company. Whirlpool markets top-of-the-line products such as refrigerators, range tops, microwaves, washers and dryers. Their brand recognition and reliability is the reason why they are so common in households and public facilities. Whirlpool is always trying to innovate and improve their current products. Recently they have been looking to advance their dryer line. Throughout the semester, Team 10 has been working closely with the Whirlpool engineers to develop a new system which will be incorporated in their current dryer technology.

Selling more than 20 billion dollars’ worth of home appliances to over 170 countries, Whirlpool Corporation is an American multinational manufacturer and a Fortune 500 company. Whirlpool markets top-of-the-line products such as refrigerators, range tops, microwaves, washers and dryers. Their brand recognition and reliability is the reason why they are so common in households and public facilities. Whirlpool is always trying to innovate and improve their current products. Recently they have been looking to advance their dryer line. Throughout the semester, Team 10 has been working closely with the Whirlpool engineers to develop a new system which will be incorporated in their current dryer technology.

The goal of this project is to deliver an electronic system that is capable of sensing garment dryness attributes (temperature, moisture, humidity, etc.) from within the dryer’s rotating baffle and communicating this information to the “appliance control unit” (ACU) without the use of physical wires. The cost of the total system solution should not exceed $5.00. This includes the cost of the ACU circuit, sensing circuit, and the interface between them. The system solution should last at least 10 to 12 years, but 20- and 30-year-old dryers are common.