ME 412 Heat Transfer Laboratory

Heat transfer devices involving phase change are known to be highly effective and thus have been widely employed in various industries, such as aerospace, electronics, agriculture, manufacturing, etc. For this project, students are expected to understand two-phase heat transfer devices through two parts of work. For the major part, each team will design, build, and test a simple heat pipe to demonstrate its two-phase operation (evaporation/condensation) at low pressure. The design objective is to effectively remove heat from a liter of boiling water. For the secondary part, each team will conduct a review on heat pipes and other two-phase heat transfer devices, exploring their types, applications, performance, as well as some existing experimental/computational works about them. On the testing day, each team will have 15 minutes to set up, demonstrate, and dissemble their pipe. Liquid cooling will be provided for the testing, as well as temperature measurements. A vacuum pump will be available to lower the pressure inside the heat pipe. Each team will also prepare a power-point slideshow or video clip for the audience to explain their design decisions, analysis and operation of their device.

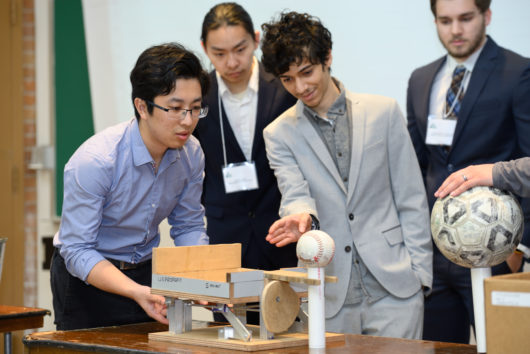

Michigan State University, College of Engineering’s Fall Design Day, 12/6/2019 in throughout the Engineering Building. Copyright 2019 Michigan State University Board of Trustees, College of Engineering All usage rights transferred to Michigan State University

ME 470 Mechanical Design & Manufacturing II

The goal in this project is to design a machine that can ink a stamp and then stamp a piece of paper in a quick, clean, and accurate manner. The teams will utilize mechanisms such as 4-bar linkages, gear sets, and cam-follower systems. Each team manufactured or utilized 3D printing to create the majority of their components. Performance will be measured by the speed by which each device can transfer ink to paper in an accurate and clean stamping process.

Michigan State University, College of Engineering’s Fall Design Day, 12/6/2019 in throughout the Engineering Building. Copyright 2019 Michigan State University Board of Trustees, College of Engineering All usage rights transferred to Michigan State University