Peckham, Inc.: Loose Fabric Roll Transfer Design

Peckham, Inc.: Laser Cutting Bed Material Handling

Adventures In Training with a Purpose: Secure Grip Ambulation Aid

Adventures In Training with a Purpose: Enhanced Foot Design Ambulation Aid

MSU Broad Art Museum: Art Hanging System for Concrete Walls

MSU Recycling Center: Debagging of Recycling

NASA/Arizona State University: Resource Utilization

Ford Motor Company: Vehicle Compliance Fresh Eyes Review Tool

NASA/Arizona State University: Robotic Explorer for Hypothesized Surfaces

AAM: EDU Sub-System Sealing

AAM: Automotive Disconnecting Differential

AAM: Axle Assembly Test Stand

NASA/Arizona State University: Landing System – Psyche Mission

Consumers Energy: Gas Compressor Emissions Recovery

MSU Department of Theatre: Scene Shop Automated Wash Station

MSU College of Engineering: Board Storage Cart

MSU Solar Racing Team: Solar Car Gear Box Creation

MSU Solar Racing Team: Solar Car Body Design

MSU Adaptive Sports & Recreation Club: Three-Wheel Drive System for Scooter

MSU Adaptive Sports & Recreation Club: Increasing Roller Sled Mobility: Phase III

MSU Adaptive Sports & Recreation Club: Sled Hockey Transfer Platform

MSU Adaptive Sports & Recreation Club: Inclusive Sports Wheelchair

MSU Department of Mechanical Engineering: Design of a Jetfire Two-Stroke IC Engine Rotary Valve

Toyota Motor North America: Vehicle Frunk Usability and Quick Latch Design

MSU Solar Racing Team: Solar Car Hub Motor Housing Design

Toyota Motor North America: Automotive Engine Hood Vibration Design

NASA/Arizona State University: Power Solutions

Pratt Miller: FSAE Front Outboard Electric Motor Assembly

Michigan AgrAbility: Portable Swarm Trap Lifter

MSU Combat Robotics Team: Combat Robotics Vehicle Design and Development

Peckham, Inc.: Loose Fabric Roll Transfer Design

Peckham, Inc. is a nonprofit organization based in Michigan involved in a variety of different industries, including service, farming, and manufacturing. It is committed to providing quality products, as well as having a positive influence in its community. Peckham has numerous programs dedicated to employing those with disabilities, or that would have otherwise found difficulty finding employment. As part of its manufacturing services, Peckham provides military grade garments and equipment to the U.S. armed forces.

In order to provide high-performance clothing and gear for the military, fabric rolls are brought by trailers to Peckham’s facility to be unloaded. Each trailer holds up to 700 fabric rolls and each roll is roughly 50 to 100 lbs. Historically, these rolls have had to be unloaded manually. Our team was tasked with designing a solution to facilitate unloading the rolls. The goal was to create a system that is more efficient and reduces manual labor. Multiple solutions were proposed and considered, taking into account their effectiveness, efficiency, and cost before selecting the final design. This solution was then manufactured, and it will be implemented in Peckham’s facility.

Michigan State University

Team Members (left to right)

Jeremy Kloss

Harbor Springs, Michigan

Jacob Stabler

Chandler, Arizona

Megan Fazio

Dearborn, Michigan

Sam Rohrer

Ann Arbor, Michigan

Pahul Kahlon

Northville, Michigan

Peckham, Inc.

Project Sponsors

Carlos Herrera

Lansing, Michigan

Erik Johnston

Lansing, Michigan

ME Faculty Advisor

Dr. Seungik Baek

Peckham, Inc.: Laser Cutting Bed Material Handling

Peckham is a nonprofit rehabilitation organization that was founded in 1976. By providing job training and competitive employment opportunities for persons with disabilities striving for independence and self-sufficiency, their clients receive high-quality products and outstanding experiences. Peckham’s Manufacturing division has long been a leading provider of high-performance clothing and gear for the military. Thousands of materials (such as fabric rolls, cut components, thread, seam tape, and accessories) are turned into high-performance garments and gear daily. Peckham strives to innovate and incorporate the latest techniques and equipment into their operations and seeks to integrate automation technology in garment packaging workstations.

Our team was focused on ergonomic and safe conditions for the operation and quick change of proper belt coverage for different working conditions. Our design was a mechanism for one operator that enables a heavy belt to be stored and pulled onto the table’s surface area when single-ply cutting needs to take place, and then pulled back onto our mechanism to use the laser cutter. Our secondary design was a mount for the exhaust hose above the gantry to prevent wearing on the hose while the gantry is moving during the working process of the single-ply cutter and laser cutter.

Adventures In Training with a Purpose: Secure Grip Ambulation Aid

Adventures in Training with a Purpose (ATP) is a nonprofit organization that aims to help those in need through purposeful physical training. ATP was established in 2015 by Jon Kolb and has continued to support vulnerable populations ever since. With the support of ATP, individuals are no longer held back by their physical limitations. Through their personalized physical training techniques, such as strength and aerobic exercises, individuals can now live a more purposeful life. ATP supports its people through various mechanisms such as Ambulation Aids that provide the greatest amount of freedom for the user while also preserving a high level of safety.

Our team was tasked with developing a secured grip design prototype for an ATP ambulation aid. The design of the grip accounted for a user who lacks the ability to grasp or squeeze a handle. To solve this issue, our design utilizes a latching mechanism to the wrist/forearm enabling the user to be secured into the crutch without having to grasp or squeeze. In addition, with our design, the latch can be released if the user falls, making it so the fall will not be obstructed by the crutch. Our secured grip design fits seamlessly into existing crutches provided by ATP, with the expectation that the combined mechanism can handle loads from 40-300 lbs.

Michigan State University

Team Members (left to right)

Brendan Zwiernik

Clarkston, Michigan

Dylan Jones

Colorado Springs, Colorado

Braeden Keener

Ferndale, Michigan

Hunter Reif

Valparaiso, Indiana

Alex Miciuda

Grosse Pointe Park, Michigan

Adventures in Training with a Purpose

Project Sponsors

Kevin Friedrich

Wexford, Pennsylvania

John Kolb

Wexford, Pennsylvania

ME Faculty Advisor

Dr. Ricardo Mejia-Alvarez

Adventures In Training with a Purpose: Enhanced Foot Design Ambulation Aid

Adventures In Training with a Purpose (ATP) is a nonprofit organization created with the goal of addressing health and movement challenges faced by underserved populations who lack access to paid rehabilitation services. ATP concentrates on “helping those most in need improve their quality of life through an adventure of purposeful, physical training”. Many of its clients face challenges related to health conditions including traumatic brain injury, stroke, paralysis, Parkinson’s disease, and various neurological disorders. Additionally, some individuals struggle with post-traumatic stress disorder resulting from combat and first responder responsibilities, along with musculoskeletal conditions.

This project was a continuation of the design work from a Fall 2023 design group to evaluate and prototype an enhanced design for a pair of wrist crutches. Our team’s focus was primarily on developing a spring-loaded crutch with a specialized foot design that adds propulsion to the user’s step. The goal was to maximize the stride length, speed, and safety of the user to improve rehabilitation, performance, and competitiveness.

Michigan State University

Team Members (left to right)

Elizabeth Sharkevich

Troy, Michigan

Shahab Khorasanizadeh

Bradenton, Florida

Jon Paul

Port-au-Prince, Haiti

Gavin Watthayu

Croswell, Michigan

Lauren Osiwala

Harrison Township, Michigan

Adventures in Training with a Purpose

Project Sponsors

Kevin Friedrich

Wexford, Pennsylvania

Jon Kolb

Wexford, Pennsylvania

ME Faculty Advisor

Dr. Andre Benard

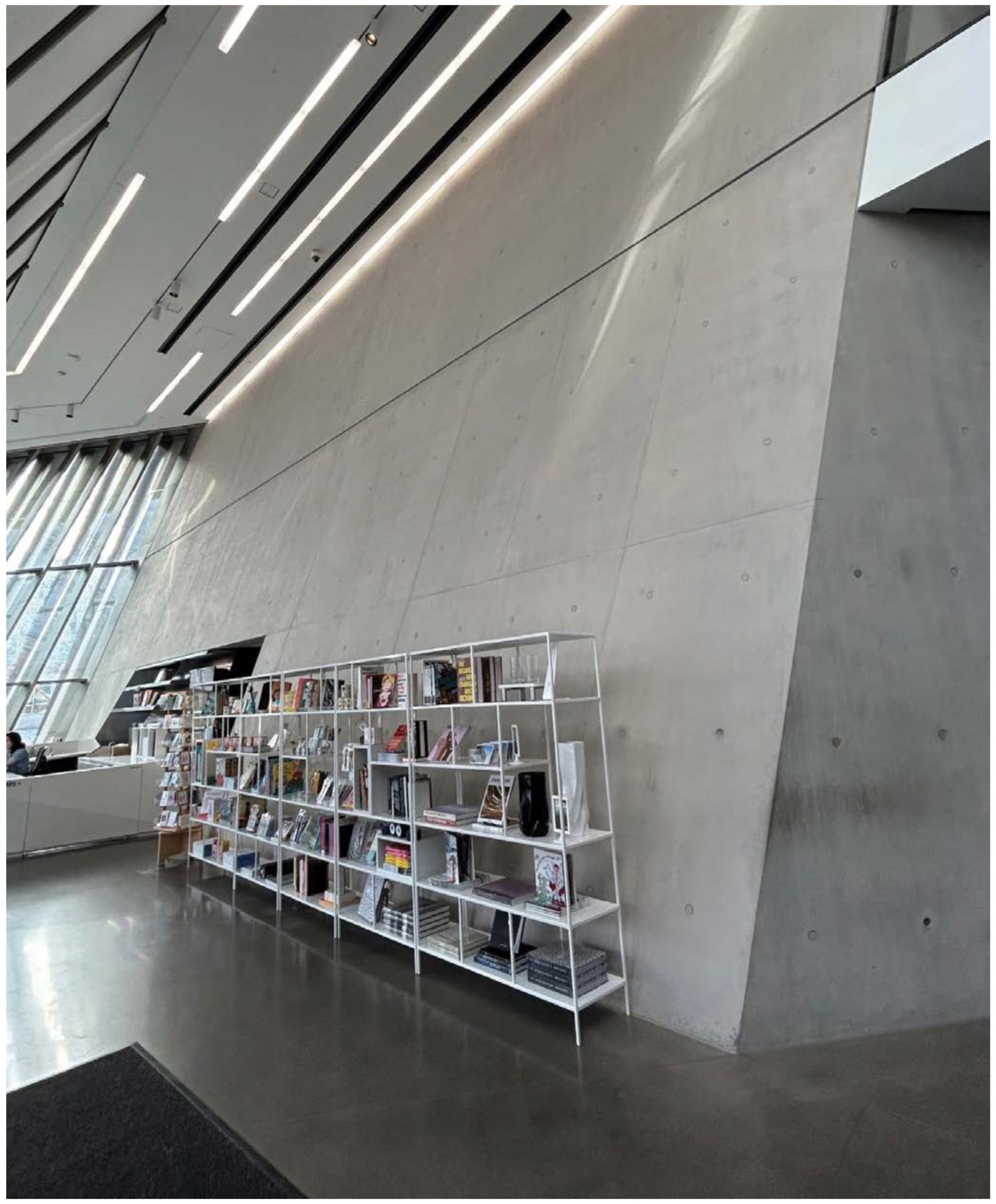

MSU Broad Art Museum: Art Hanging System for Concrete Walls

Opening its doors in 2012, the MSU Broad Art Museum is a leading institution renowned for its world-class status and an extensive permanent collection comprising over 10,000 works. The museum focuses primarily on contemporary art, serving as a vibrant hub for artistic discourse from all over the world. The museum’s architecture, designed by renowned architect Zaha Hadid, stands out with distinct angles and unique structural elements. This design contributes to the museum’s appeal, providing a dynamic environment for art enthusiasts and the public alike.

This building features slanted concrete walls. The walls contain casting holes spaced regularly throughout the area, which have been capped with cast plugs. These holes offer an excellent opportunity to hang various items, from labels and artwork to brackets and work platforms. Our team was tasked with designing a hardware system that will enable these elements to be hung on the concrete walls. It is important to note that concrete is prone to cracking, chipping, and discoloring, so it was important for our group to ensure the safety of the structure and preserve the building’s integrity. The end goal was to create a modular system of parts that could work together safely and display anything from a light painting to a heavy statue.

Michigan State University

Team Members (left to right)

Gabriel Johnson

Monroe, Michigan

Evan Hampel

Clarkston, Michigan

Michael Romzek

Grand Blanc, Michigan

Noah Roux

Clarkston, Michigan

Bryant Hixson

Novi, Michigan

MSU Broad Art Museum

Project Sponsor

Brian Kirschensteiner

East Lansing, Michigan

ME Faculty Advisor

Dr. Galit Pelled

MSU Recycling Center: Debagging of Recycling

The Michigan State University Recycling Center is a comprehensive and environmentally conscious facility dedicated to promoting sustainability on campus. Operating with a commitment to waste reduction and resource conservation, the center employs state-of- the-art recycling processes to efficiently manage various materials, including paper, plastic, glass, and electronics. Through its robust operation, the center aims to minimize landfill contributions, educate the university community on responsible waste disposal practices, and contribute to a greener future. By fostering a culture of environmental stewardship, the Michigan State University Recycling Center plays a pivotal role in advancing the institution’s sustainability goals, creating a campus-wide impact on waste management and promoting a more eco-friendly and responsible community.

The center collects and hand sorts over 6 million pounds of recycling annually. Some of the recycled material arrives at the facility in plastic bags. These plastic bags are received mainly from stadiums and can contain a lot of liquid and food waste. Therefore, hand-processing these bags can be a very messy process. Unfortunately, commercialized debagging machines on the market are too large for the facility. For that reason, our team decided to replicate the already existing concept but on a smaller scale to fit the means of the facility. The intended goal for the project was ultimately to eliminate the need for any debagging by hand, all while increasing the efficiency of the recycling process.

Michigan State University

Team Members (left to right)

Benjamin Van Hove

Shelby Township, Michigan

David Mueller

Shelby Township, Michigan

Kyle Pahl

Plymouth, Michigan

Ryan Leinweber

Royal Oak, Michigan

Austin Crawford

Colorado Springs, Colorado

MSU Recycling Center

Project Sponsor

Julia Haidler

East Lansing, Michigan

ME Faculty Advisor

Dr. Galit Pelled

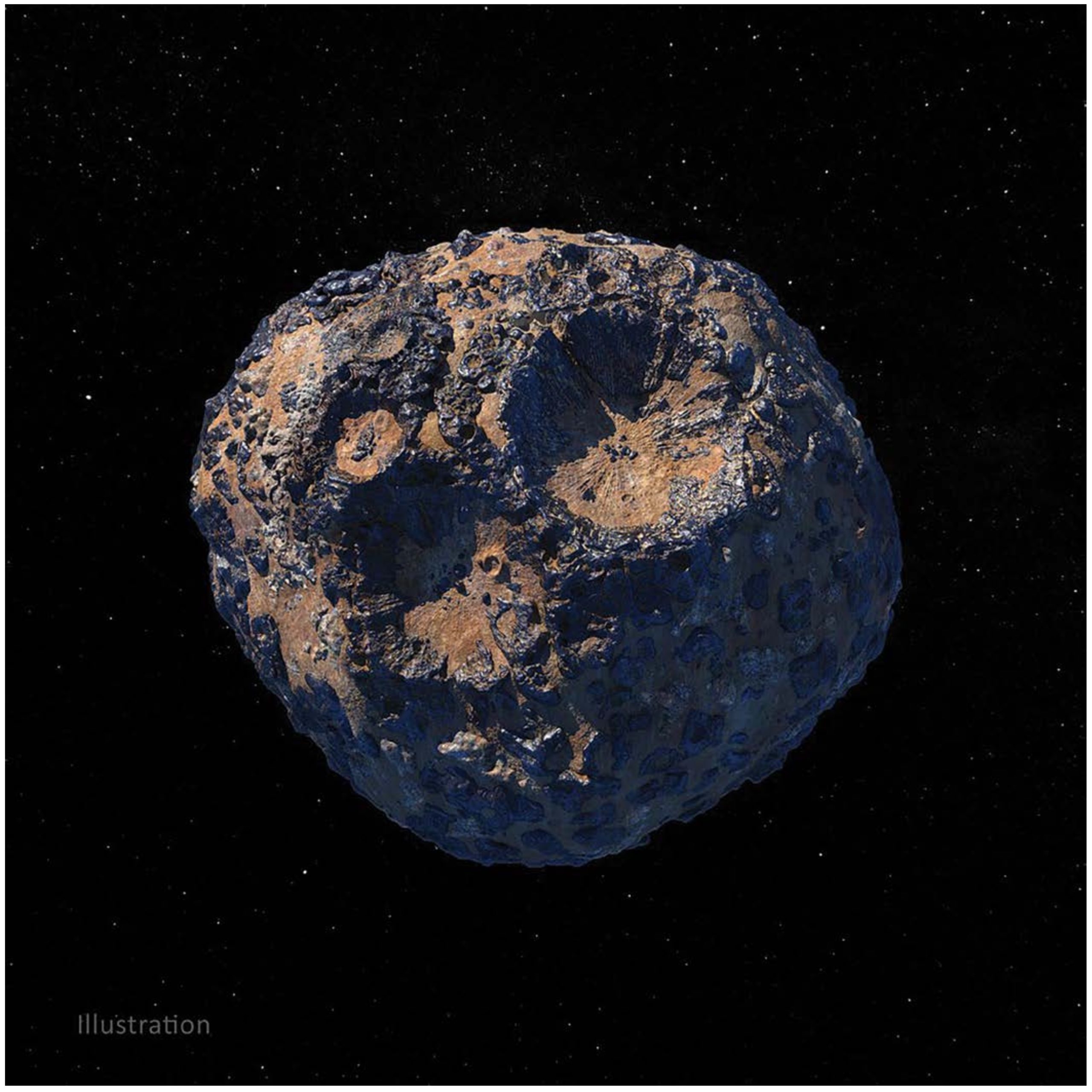

NASA/Arizona State University: Resource Utilization

The NASA Psyche Mission is an orbiter mission to the metal-rich asteroid, Psyche, which is in the asteroid belt between Mars and Jupiter. The spacecraft, launched in October 2023, and scheduled to arrive at the asteroid in mid-2029, will study the asteroid from orbit and will not land on the surface. It is possible to imagine, however, that after learning about Psyche from orbit, there may be scientists and engineers interested in proposing a future mission to explore or sample the surface. To save on mass and cost, such a mission might need to consider innovative yet feasible solutions for making use of materials found at the asteroid for the fabrication of parts, tools, or other aspects of robotic surface exploration.

Using the asteroid’s known and hypothesized environmental and surface conditions, the proposed design was a method to sort and identify the various materials found on Psyche’s surface. The hypothesized surface conditions provided design parameters for the mechanism’s sorting features to separate the various materials found in Psyche’s dust-like surface. The design includes a mechanical sorting system to account for potential materials of varying size, shape, and other defining factors. The design mechanism accounted for potential materials not previously noted or hypothesized. The design integrated light spectroscopy to further identify the materials once they have been sorted. This will allow for testing and identification of surface materials without sample collection intended to return to Earth. The surface conditions of Psyche are still unknown, so conditions including a mostly flat metallic surface, a flat metallic surface with metal and rocky debris, a rough or high-relief metallic surface and rocky terrain, and a surface with high-relief metallic crater walls were considered. The proposed design aimed at maximum scientific discovery given current knowledge

Michigan State University

Team Members (left to right)

Patrick Ryan

South Lyon, Michigan

Andrew Tabaka

Troy, Michigan

Aisyah Mahira

Jakarta, Indonesia

Sara Purdue

Newburgh, Indiana

Branton Guri

Sterling Heights, Michigan

Ryan Geisler

Troy, Michigan

NASA/Arizona State University

Project Sponsor

NASA Psyche Mission

Tempe, Arizona

ME Faculty Advisor

Dr. Norbert Mueller

Ford Motor Company: Vehicle Compliance Fresh Eyes Review Tool

Ford Motor Company, a family-oriented global enterprise, embodies shared ideals that resonate across continents and generations. With over 120 years of history, Ford has adeptly navigated change, emerging as a leader in the automotive industry while maintaining a steadfast commitment to service. Expanding its focus beyond traditional vehicles, Ford now prioritizes services, experiences, and software, aiming to enrich lives and enable dreams worldwide. Its mission is clear: to contribute to a world where every individual can freely pursue their aspirations unencumbered by barriers. By bridging distances and fostering connections, Ford unlocks possibilities and ignites the spirit of adventure. Ford remains dedicated to building a better world for generations to come.

This project is to modernize Ford’s compliance audit process, known as “Fresh Eyes Reviews,” for production vehicles. These reviews ensure vehicles meet and maintain regulatory standards throughout production. Initially a manual process, it relied on a cumbersome spreadsheet, making it challenging to perform checks efficiently. Our team developed an understanding of the existing process, identified areas of improvement, evaluated technological solutions, and developed a user-friendly tool. This tool efficiently guides auditors through vehicle evaluations, streamlining the “Fresh Eyes Review” process.

Michigan State University

Team Members (left to right)

Colin Graf

Dansville, Michigan

Luke Aman

Highland, Michigan

Taylor Page

Ann Arbor, Michigan

James Fordyce

Petoskey, Michigan

Trent Warren

Petoskey, Michigan

Ford Motor Company

Project Sponsors

Sara Buchel

Dearborn, Michigan

Justin Khami

Dearborn, Michigan

Mike Landry

Dearborn, Michigan

ME Faculty Advisor

Dr. Mohsen Zayernouri

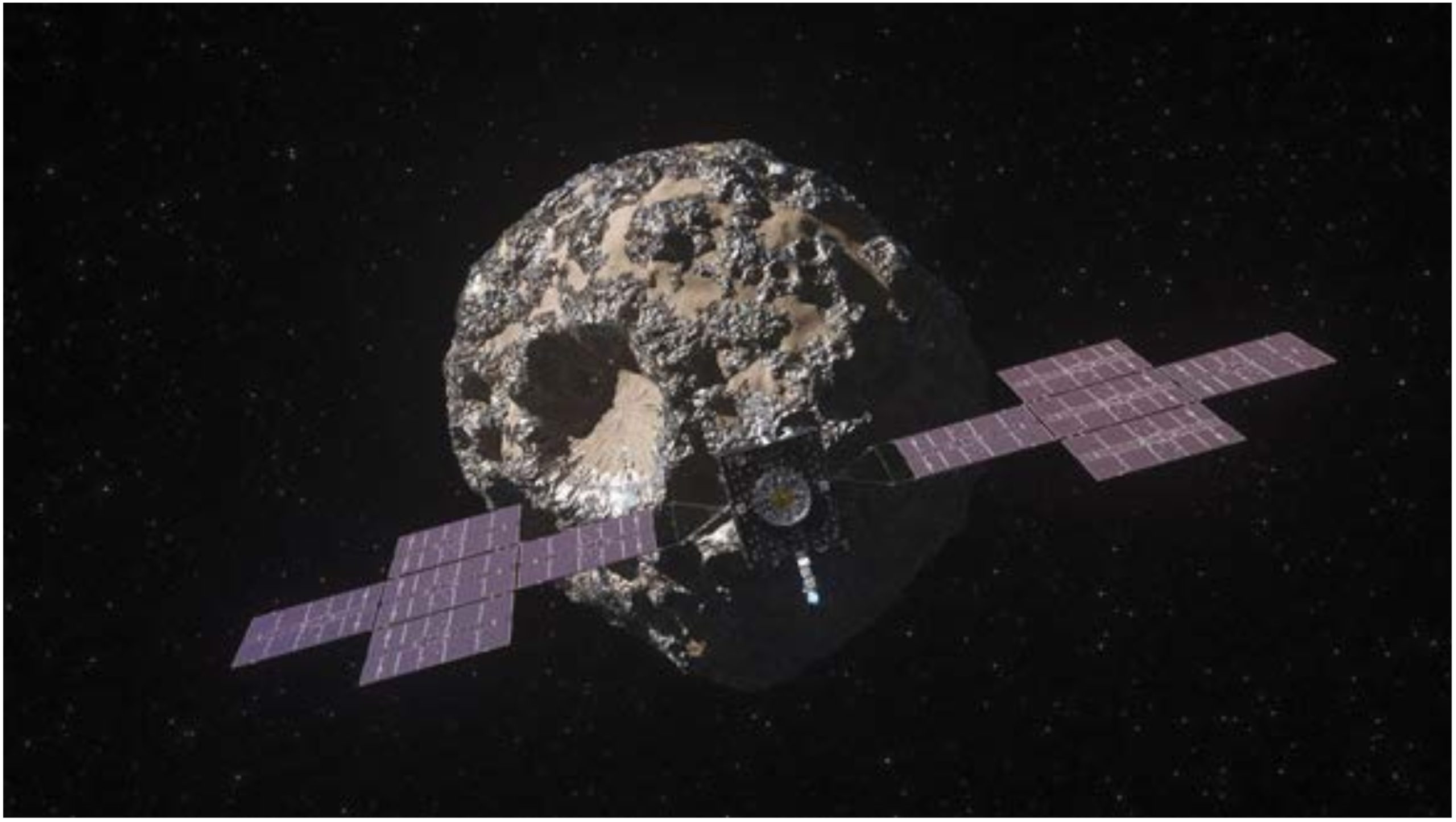

NASA/Arizona State University: Robotic Explorer for Hypothesized Surfaces

The NASA Psyche Mission, led by Arizona State University, is a mission to send an orbiter to the metal-rich asteroid Psyche. The asteroid, 16 Psyche, is contained within the asteroid belt between Mars and Jupiter. This orbiter, which was launched on Friday, October 13, 2023, is en route to reach the asteroid mid-2029. The key element that makes the Psyche asteroid unique is that it is not composed of rock and ice, but rather mostly metallic substances. Its surface is hypothesized to be made from large amounts of nickel, iron, and silicate materials. Because of this, Psyche has been compared to metallic cores of terrestrial planets, including that of Earth. This leads Psyche to be highly valuable in the research of planetary cores and the processes that lead to planet formation. Research of this caliber has not been conventionally possible before given the extremely harsh environment that lies deep below the crust and mantle of Earth.

While the mission described above is purely conducting orbital studies, it is likely that a trip to land on Psyche will be advantageous to further the research on the surface. Our team’s project was to design a robotic explorer that is capable of adapting to the multiple hypothesized surfaces of Psyche. The surface of the asteroid has been proposed to be mostly flat and metallic with metal or rocky debris. It is also known that there is likely rough and high-relief terrain similar to formations seen in deserts and mountainous regions. Lastly, the surface of the asteroid has been reported to contain large craters. This extreme variation yields a unique problem that must be solved by an explorer that is adaptive to the environment that exists on Psyche. Given the uncertainty of the surface, many challenges were to be overcome by our design team and the systems included in our robotic explorer.

Michigan State University

Team Members (left to right)

Nicholas Malcolm

Brighton, Michigan

Drew Darin

Clarkston, Michigan

Ethan Wise

Clarkston, Michigan

Sara Moscone

Clarkston, Michigan

Justin Schmitz

Fowler, Michigan

Sean Blanchard

Warren, Michigan

NASA/Arizona State University

Project Sponsor

NASA Psyche Mission

Tempe, Arizona

ME Faculty Advisor

Dr. Ranjan Mukherjee

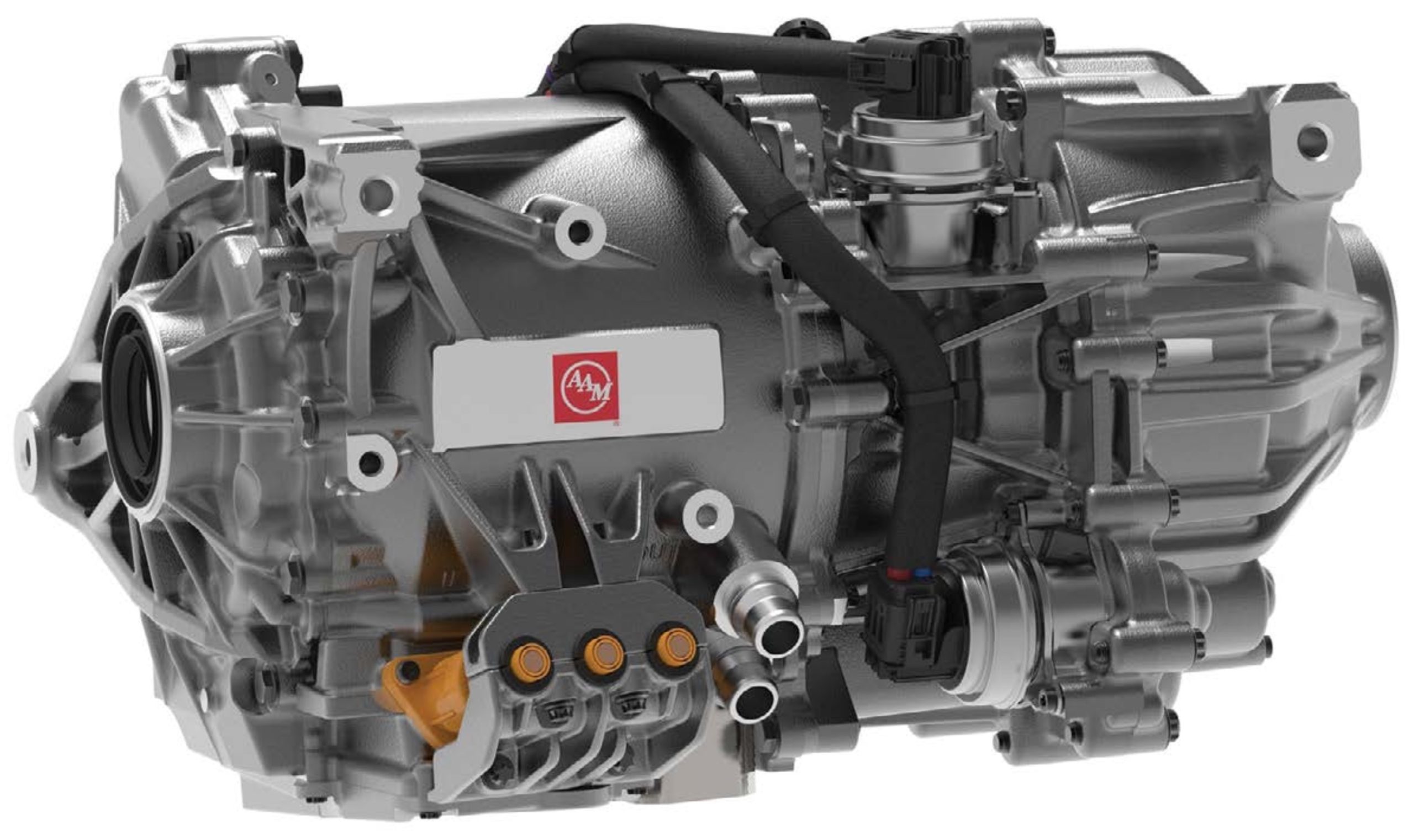

AAM: EDU Sub-System Sealing

American Axle & Manufacturing (AAM) is a leading global Tier 1 Automotive and Mobility Supplier designing and manufacturing Driveline and Metal Forming technologies to support electric, hybrid, and internal combustion vehicles. Headquartered in Detroit Michigan, AAM has over 80 facilities in 18 countries. AAM’s Driveline Division provides rear-wheel drive, all-wheel drive, and four-wheel drive systems for various engine types: IC, hybrid, and electric. AAM’s Driveline product portfolio optimizes mass and increases efficiency and NVH without sacrificing performance.

The team worked to investigate various methods to improve the sealing and sealing interfaces between the oil-cooled Inverter sub-system and oil-cooled eMotor sub- systems in AAM’s next generation 3-in-1 EDU to improve the robustness and reduce the overall design complexity. The team adequately sealed the Inverter sub-system from the eMotor sub-system in order to prevent damage to the system from oil ingress.

Michigan State University

Team Members (left to right)

Jonathon Fudala

South Lyon, Michigan

Aditya Swarnkar

Dubai, United Arab Emirates/ New Delhi, India

Nicole Burcon

Pinckney, Michigan

Keya Baxi

Troy, Michigan

Aditya Tarle

Pune, India

AAM

Project Sponsor

Michael Zarzycki

Detroit, Michigan

ME Faculty Advisor

Dr. Seungik Baek

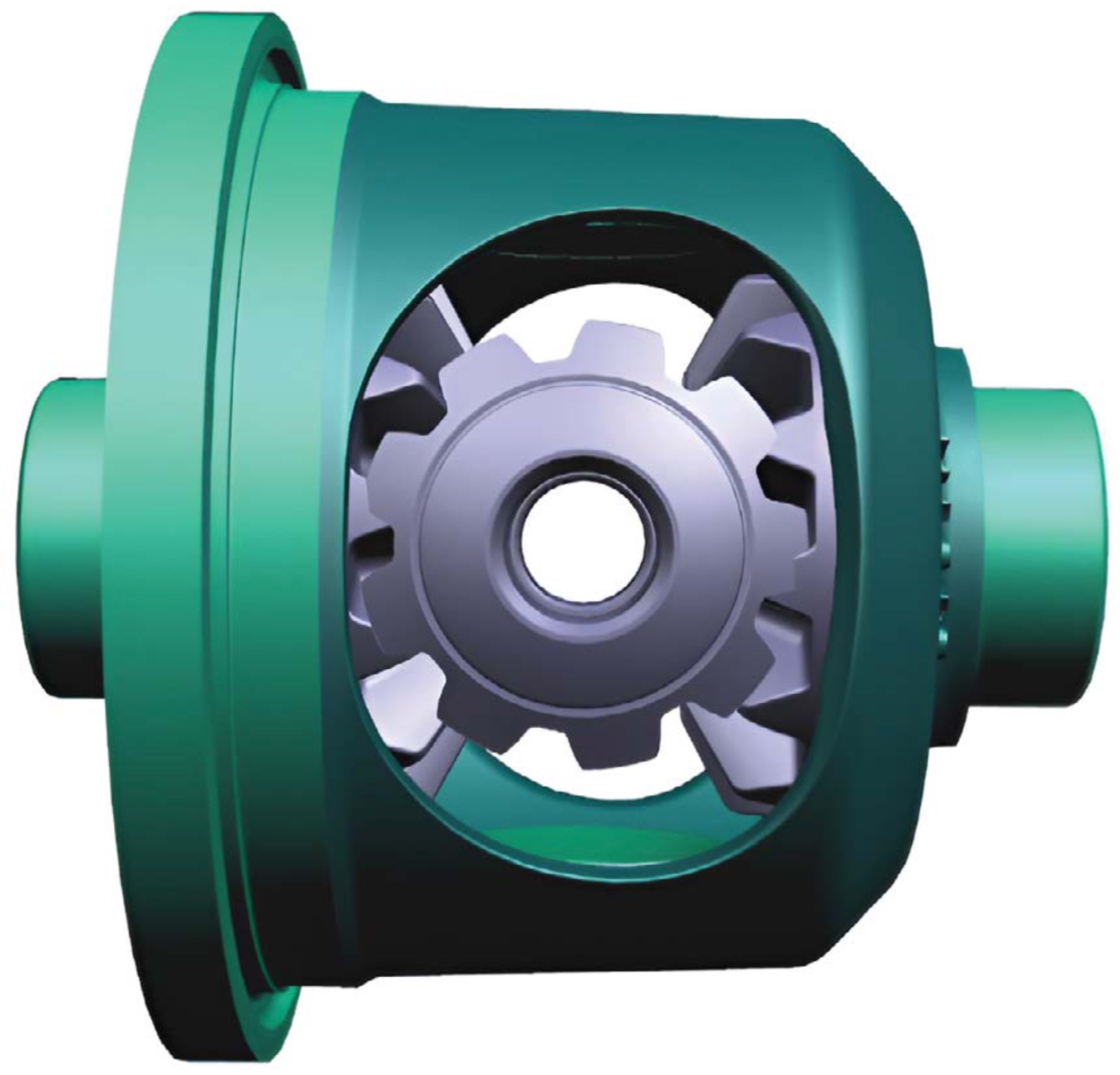

AAM: Automotive Disconnecting Differential

American Axle & Manufacturing (AAM) is a global leader in automotive driveline and drivetrain components. Founded in 1994, AAM provides innovative solutions to enhance vehicle performance, efficiency, and safety with a diverse portfolio, including axles, driveshafts, and power transfer units. AAM serves major automakers worldwide. Committed to excellence and technological advancement, AAM continuously invests in research and development, earning a reputation for reliability and innovation in the automotive industry.

Our team explored various methods and mechanisms aimed at disconnecting an axle shaft from the primary power or driving source. Our objective was to design a disconnecting device that could fit entirely within the packaging space of a standard open differential.

Ultimately, this change enhanced system efficiency, decreased parasitic drag from unused components, and achieved improved fuel economy with a reduction in emissions. Integrating the disconnect mechanism within the differential offered several advantages. It reduced the total axial space required for packaging compared to conventional side shaft disconnect systems, simplified assembly for the axle manufacturer, and lowered the total number of parts and part complexity.

Michigan State University

Team Members (left to right)

Manav Shah

Novi, Michigan

Andrew Ferguson

Newport Beach, California

Connor Casey

Dowagiac, Michigan

Colin Boulard

South Lyon, Michigan

Aidan Dobbie

South Lyon, Michigan

AAM

Project Sponsor

Steve Doud

Detroit, Michigan

ME Faculty Advisor

Dr. Ahmed Naguib

AAM: Axle Assembly Test Stand

American Axle & Manufacturing (AAM) is an American manufacturer of automobile driveline and drivetrain components and systems. Headquartered in Detroit, Michigan with over 80 facilities in 18 countries, AAM is a global Tier 1 Automotive and Mobility Supplier. Founded in 1994, by Richard E. Dauch, AAM has grown from five former GM plants located throughout the Midwest to a multi-billion-dollar global company that is one of the largest and most respected Tier 1 automotive suppliers in the world. AAM engineers and manufactures Driveline and Metal Forming technologies to support electric, hybrid, and combustion vehicles.

AAM’s Driveline division provides rear-wheel drive (RWD), all- wheel drive (AWD), and four-wheel drive (4WD) systems. AAM’s Driveline product portfolio optimizes mass and increases efficiency and noise, vibration, and hardness (NVH) without sacrificing performance. AAM boasts advanced products, processes, and systems technologies like their QUANTUM® and EcoTrac® that are smarter, lighter, more powerful, and more efficient. AAM’s Metal Forming business unit represents the largest automotive forging enterprise in the world, providing engine, transmission, driveline, and safety-critical components for light, commercial, and off-highway vehicles.

The Structural Housing and Axle Tube engineering team at AAM is considering new methods for testing front and wheel axle systems. Our team was assigned the task of designing, building, and programming a scale model test stand capable of reproducing real-world driving conditions to view and measure oil flow within an axle assembly. The dynamic or “real-world” driving conditions being simulated through our programs are acceleration, braking, turning, bumps, inclines, and declines using table positioning motors. Our team’s goal was to configure a system capable of recreating all these conditions in a working scale model to represent how our fully realized system would function.

Michigan State University

Team Members (left to right)

Poom Wichitrakanlikit

Bangkok, Thailand

Nick McCarthy

Brighton, Michigan

Mason Koudelka

Brighton, Michigan

Harshil Jain

New Delhi, India

Noah Iung

Saint Johns, Michigan

AAM

Project Sponsor

Jim Borowiak

Detroit, Michigan

ME Faculty Advisor

Dr. Ricardo Mejia-Alvarez

NASA/Arizona State University: Landing System – Psyche Mission

In 1852, the asteroid sometimes referred to as 16 Psyche, named for the Greek Goddess of the soul, was discovered by Italian astronomer Annibale de Gasparis. Now, the Psyche Mission led by NASA alongside Arizona State University, seeks to explore this metal-rich asteroid which orbits our Sun and resides within the asteroid belt between Mars and Jupiter. To achieve this goal, a spacecraft was launched from Kennedy Space Center on October 13, 2023 with the intent of reaching Psyche in 2029. Modern exploration of Psyche from afar has led scientists to uncover the potential for large amounts of metal to exist among rock throughout its body, producing the concept that it may be a planetesimal core, a remnant of our early solar system. The purpose of exploring Psyche is to hopefully gain a better understanding of how the core of our home planet of Earth developed.

The objective of this project was to formulate a manner by which a future mission may physically land on Psyche to conduct further exploration. This process included performing research on past NASA landing systems to not only analyze their application in this case but to invent solutions to Psyche specific situations. At this point, Psyche’s actual appearance and geological makeup are unknown and will remain as such until the launched spacecraft comes closer to approaching the asteroid. Therefore, it was important to research various styles of spacecraft and landing gear in order to incorporate relevant aspects into the design, formulated to consider the most likely geological outcomes based on what is known today. Considering that nothing like Psyche has ever been examined up close, it was also important to be mindful of the many variables of touching down on a dense, irregularly shaped, low- gravity body when determining the best features to include in the proposed landing system.

Michigan State University

Team Members (left to right)

Atharva Burande

Troy, Michigan

Carter Beck

Waterford, Michigan

Catherine Schenone

Bridgewater Township, New Jersey

Enido Shyti

Shelby Township, Michigan

Noah Benson

Bloomfield Hills, Michigan

NASA/Arizona State University

Project Sponsor

NASA Psyche Mission

Tempe, Arizona

ME Faculty Advisor

Dr. Ahmed Naguib

Consumers Energy: Gas Compressor Emissions Recovery

Discover the heart of Consumers Energy’s vital role in Michigan’s energy landscape. As a leading natural gas and electric utility, Consumers Energy powers communities across the state. The Gas Compression department, an integral part of the natural gas business unit, is tasked with managing specific locations within the state’s pipeline system. Their focus is to improve pressure for warm season storage and facilitate the processing of stored gas during cold season withdrawals. Consumers maintains 41 gas compressors spanning different eras, committed to efficiency and reliability. When it comes to sustainability, Consumers Energy is continuously committed to prioritizing their carbon footprint through ongoing efforts and vigilant upkeep.

Although by design, packing systems on reciprocating gas compressor rods have leak points that release methane into the atmosphere. A goal has been set to reduce fugitive emissions from its infrastructure by 2030. Our team was tasked with resolving methane emissions from the known continuous leak points. To gain better insight, we visited the Freedom Gas Compressor station, one of the facilities where this problem was occurring. The goal was to eliminate contaminant materials, such as oil carryover and physical media, while boosting pressure to utilize methane as supplemental fuel for the compressor facility’s fuel system. For our project, we developed schematics of our proposed ideas and process and instrumentation diagrams (P&IDs) that ultimately helped us when reflecting on an idea that would cut emissions from entering the atmosphere. By delivering these components, our team was able to facilitate the implementation of an effective solution to mitigate methane emissions, contributing to Consumers Energy’s broader sustainability objectives.

Michigan State University

Team Members (left to right)

Adolfo Lopez

Holland, Michigan

Matthew Mozariwskyj

Macomb, Michigan

Justin Gauthier

Sterling Heights, Michigan

Jacob Smith

New Buffalo, Michigan

Ethan Azeez

Livonia, Michigan

Consumers Energy

Project Sponsors

Martin Barnaby

Manchester, Michigan

Clayton Tacey

Manchester, Michigan

ME Faculty Advisor

Dr. Abraham Engeda

MSU Department of Theatre: Scene Shop Automated Wash Station

The Scene Shop, formally known as the Performing Arts Teaching Lab, is where all the sets needed by the Department of Theatre and College of Music opera program are created. It is a 9,370 square foot facility located on the southeastern side of campus. With 22 ft tall ceilings, the building is large enough to construct an entire scene. Updated with new technology and equipment, this new space now enables two shows to be worked on at the same time.

Our team was tasked with designing an automated wash station for the Michigan State University Scene Shop. When the Scene Shop first receives its stage components, the parts are covered in various kinds of dirt and grease, resulting in countless wasted hours spent cleaning each part before it is ready to be used in construction. The previous process for cleaning the metal was to use rags and hand wipe down each individual piece of metal. Our mechanism was designed to have an automatic feed operation that would simultaneously wash and scrub any unwanted substances off the surfaces. Our automated wash station is also able to move anywhere it is needed as it has its own tank of cleaning solution. With our automated washing station, we will save the Scene Shop both time and energy.

Michigan State University

Team Members (left to right)

Mitchell Carroll

West Bloomfield, Michigan

Luke Muller

Farmington Hills, Michigan

Katelyn Szafranski

Ann Arbor, Michigan

Ali Lewis

Cincinnati, Ohio

Zach Hetfield

East Lansing, Michigan

MSU Department of Theatre

Project Sponsor

Marc White

East Lansing, Michigan

ME Faculty Advisor

Dr. Indrek Wichman

MSU College of Engineering: Board Storage Cart

The MSU College of Engineering organizes numerous yearly events, providing a platform for students to showcase their projects on foam boards measuring 32 inches by 40 inches. Currently, the College of Engineering manages a collection of 200 of these boards. Historically, the process of counting, transporting, and setting up these boards for each event has been challenging. Issues such as limited maneuverability, inaccessibility, and difficulty in accurately determining the quantity of boards in the storage cart have complicated the workflow. Consequently, additional efforts have been required to overcome these limitations, impacting the efficiency of event preparations.

The goal of this project was to design and create a robust and versatile storage cart tailored for the easy transportation and storage of foam boards across MSU’s campus. The cart was built to overcome specific challenges, such as loading and unloading from vehicles, traversing various terrains, maneuvering into small areas such as storage rooms and elevators, and ensuring accessibility and ease of use for individuals of varying heights. Furthermore, the design emphasizes ease of repair and replacement for components subject to heavy wear, such as wheels, and incorporates ventilation features to prevent the entrapment of rodents.

Michigan State University

Team Members (left to right)

Alex Johnson

Waterford, Michigan

Eric Luo

Auburn Hills, Michigan

Kenny Yue

Ann Arbor, Michigan

Miles Peters

Ann Arbor, Michigan

Ryan Qualley

Wixom, Michigan

MSU College of Engineering

Project Sponsors

Sandy Christlieb

East Lansing, Michigan

Katy Luchini Colbry

East Lansing, Michigan

ME Faculty Advisor

Dr. Zhaojian Li

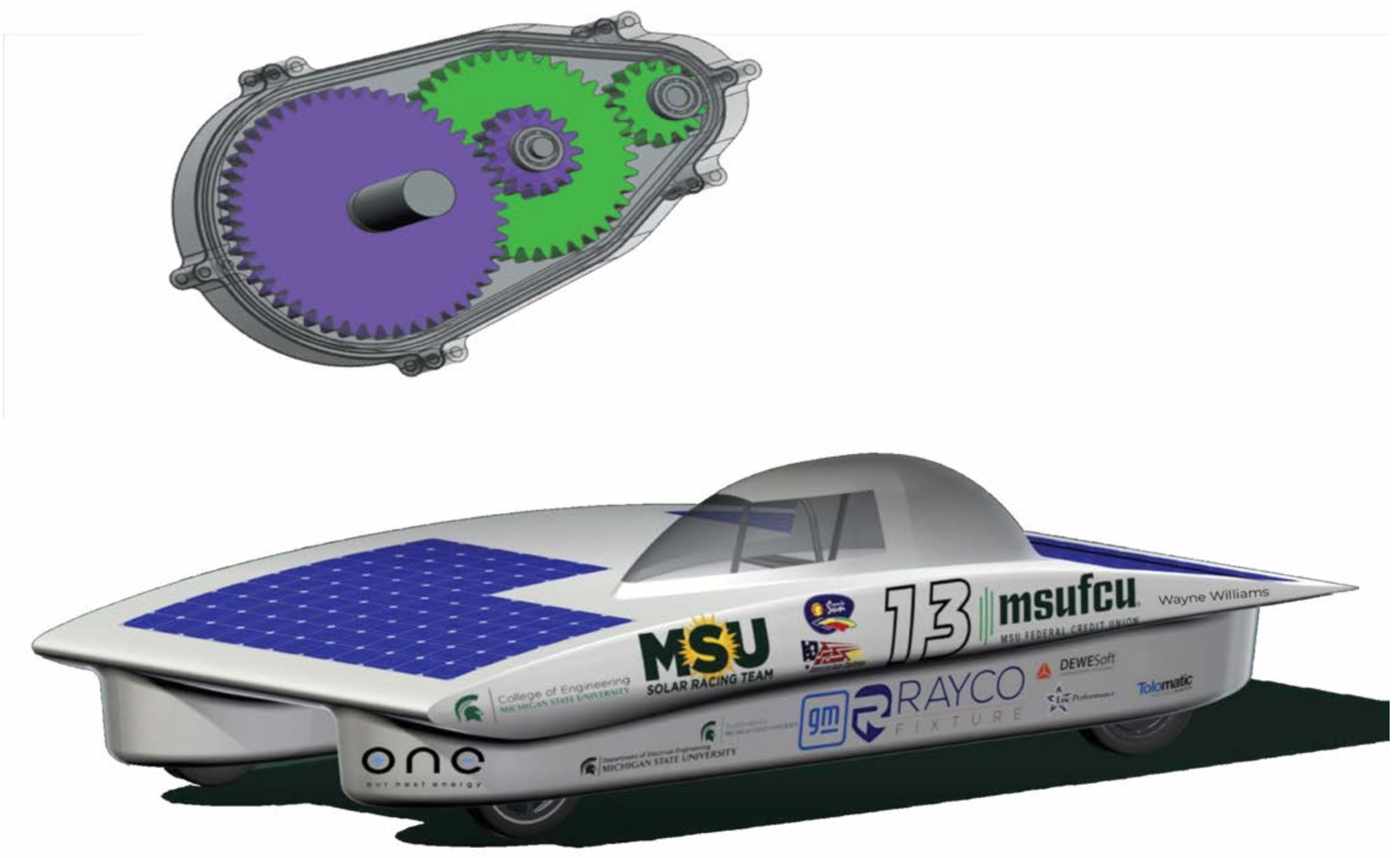

MSU Solar Racing Team: Solar Car Gear Box Creation

The Michigan State Solar Racing Team (SRT) is a student-run organization that showcases innovation and engineering excellence in renewable energy. Comprised of students from various engineering disciplines, the team dedicates itself to designing, building, and racing solar-powered vehicles. Its primary objective is to develop highly efficient and innovative solar vehicles that compete in national and international solar car challenges. These competitions, such as the Formula Sun Grand Prix and the American Solar Challenge, take place across different challenging terrains and routes, testing the limits of solar- powered transportation.

MSU SRT commissioned the development of an advanced gearbox to enhance the efficiency of its solar-powered vehicle, ‘Cynisca.’ Previously, a Spring 2023 Capstone team designed and modeled a gearset and housing intended for future manufacturing and testing. That future has come with a transition from concept to reality. Students designed updates to better fit MSU SRT’s mechanical needs and improve the manufacturability of the drivetrain. Originally tailored for a 600-pound car, but adapted for increased weight to 950 pounds, the gearbox underwent precise adjustments. Utilizing advanced manufacturing techniques for the housing and sourcing high-quality gear contacts, we assembled each component, resulting in a mechanism designed to enhance the solar car’s performance and cost efficiency.

Michigan State University

Team Members (left to right)

Benjamin Roraff

Grosse Pointe Farms, Michigan

Garrett Puehler

Lyons, Ohio

Kory Knickerbocker

Otisville, Michigan

Ethan Smydra

Rochester, Michigan

Daniel Erfani Zachi Yazd

Birmingham, Michigan

MSU Solar Racing Team

Project Sponsors

Woongkul (Matt) Lee

East Lansing, Michigan

Rachel Schenck

East Lansing, Michigan

ME Faculty Advisor

Dr. Thomas Pence

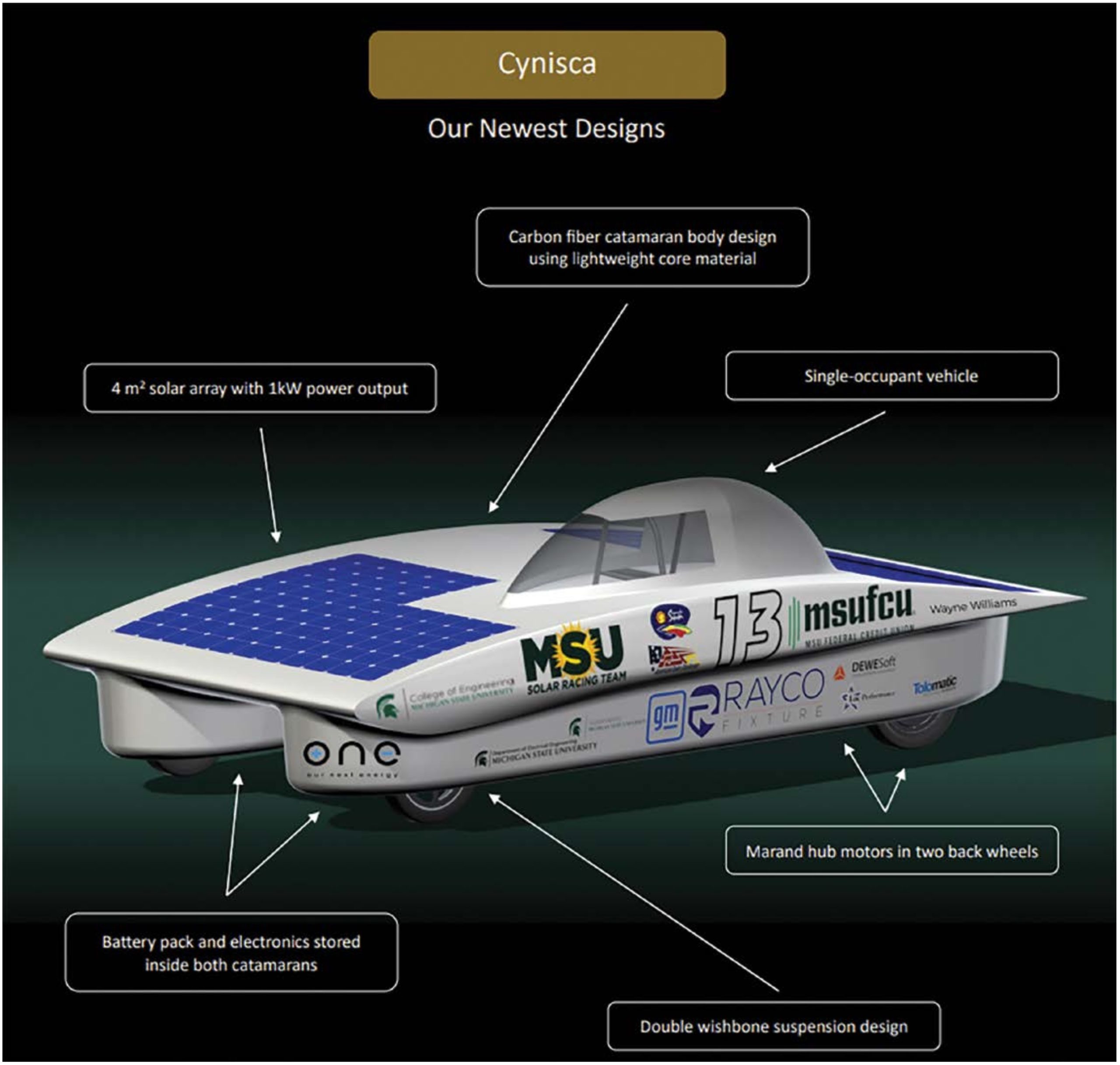

MSU Solar Racing Team: Solar Car Body Design

Michigan State University’s Solar Racing Team (MSU SRT) is a student-led undergraduate team that designs, manufactures, and races full-sized solar powered electric vehicles. Over the past 22 years, they have designed and built four single-occupant vehicles and one multi- occupant vehicle. Its most recent build is a cost-effective single- occupant vehicle named ‘Cynisca.’ The goal for this vehicle is to successfully compete in the 2024 Formula Sun Grand Prix and American Solar Challenge and perform well with consistency. This requires the car to travel over 2000 miles over the span of a few days.

The objective was to design a body that was aerodynamic, lightweight, and easy to manufacture, aiming to compare and advise on the manufacturability versus theoretical performance of carbon fiber aeroshells, monocoque body/chassis, and segmented flat paneling for future car build cycles. The body’s design aims to provide a path for air around the car, effectively minimizing the formation of vortexes and high-pressure zones, thereby reducing the drag on the vehicle. By mitigating drag force, the car requires less energy to move, enabling greater efficiency. The current body for the solar car represented a significant advancement over previous iterations; however, there remained ample opportunity for enhancement. Further development was necessary to optimize material usage, refine aerodynamic performance, and streamline manufacturing processes, thereby ensuring the continued progression towards an even more efficient and competitive solar car design.

Michigan State University

Team Members (left to right)

Angelo Bartolome

Rochester Hills, Michigan

Tanaka Chonyera

Gaborone, Botswana

Isaiah Devougas

Clinton Township, Michigan

Sammy Dickow

Novi, Michigan

Tyra Treadway

Detroit, Michigan

MSU Solar Racing Team

Project Sponsor

Ethan Stull

East Lansing, Michigan

ME Faculty Advisor

Dr. Ahmed Naguib

MSU Adaptive Sports & Recreation Club: Three-Wheel Drive System for Scooter

The MSU Adaptive Sports & Recreation Club was founded in 2014 as an organization that seeks to promote the health, social, and psychological benefits of physical activity for individuals with physical disabilities. MSU Adaptive Sports aims to establish a space for athletes with physical disabilities and able-bodied volunteers to come together and create an integrated community of peers. The organization hopes to eradicate negative stereotypes about disabilities by highlighting the strengths and abilities of these individuals. The MSU Adaptive Sports & Recreation Club offers a variety of sports including tennis, basketball, and hockey. The organization hosts six events every week, with all equipment provided and everyone welcome!

The objective of this project was to develop a method for a three-wheel electric scooter to navigate through winter weather conditions. Our sponsor, Piotr Pasik, uses an electric scooter as his main means of transportation, both indoors and outdoors. The scooter would often get stuck when driving on icy and snowy sidewalks. Piotr addressed this challenge with the Mechanical Engineering Department, hoping a capstone group could find a solution to the problem. We proposed a three-wheel drive system to integrate with the current powertrain. The scooter is powered by two motors, one powering the two rear wheels, and the other powering the front wheel. The main challenge of this project was integrating the two motors so they work together. Because they are powered separately, they needed to be synced in some way. In addition, the correct power distribution and wheel speed needed to be determined and implemented.

Michigan State University

Team Members (left to right)

Michael Taylor

Farmington Hills, Michigan

Elan Krakoff

West Bloomfield, Michigan

Gina Sapiano

Shelby Township, Michigan

Maggie Le

Brighton, Michigan

Ozan Wood

Farmington Hills, Michigan

Ben Lemke

Rochester Hills, Michigan

MSU Adaptive Sports & Recreation Club

Project Sponsor

Piotr Pasik

East Lansing, Michigan

ME Faculty Advisor

Dr. Guoming Zhu

MSU Adaptive Sports & Recreation Club: Increasing Roller Sled Mobility: Phase III

The goal of MSU’s Adaptive Sports & Recreation Club is to increase inclusivity in extracurriculars by promoting the benefits of physical activity to individuals with physical disabilities. They seek to eliminate negative stereotypes towards disability by shifting the focus to the abilities of physically disabled individuals. Adaptive recreation options that they offer include adaptive rowing, adaptive track & field, handcycling, wheelchair basketball, wheelchair floorball, and wheelchair tennis. The Adaptive Sports & Recreation Club helps athletes make healthy choices about exercise and nutrition, meet other athletes with physical disabilities, and become part of a disability community. It improves the athlete’s confidence by helping them succeed in new challenges.

While they would like to add roller sled hockey to the list of sports they offer, significant improvements to the mobility of the sleds must be made. Sled hockey utilizes sleds with blades or wheels to move on the desired terrain. With the difficulty of scheduling regular ice time at Munn for practice and games, the Adaptive Sports & Recreation Club utilizes donated roller sleds and courts at MSU’s Demonstration Hall. The goal of this project is to improve the mobility of roller hockey sleds to move with ease for persons of a wide range of disabilities on the unique, higher friction terrain of Demonstration Hall. Our design incorporates mechanisms from prior semesters’ design teams with the addition of our own improvements to tackle the remaining challenges and provide the best experience for both novice and experienced users.

Michigan State University

Team Members (left to right)

Gabriel Birchmeier

White Lake, Michigan

Brad Kolinski

Kalamazoo, Michigan

Selena Vidojevski

Canton, Michigan

Maya Patel

Canton, Michigan

Drew Goodman

Locust Valley, New York

MSU Adaptive Sports & Recreation Club

Project Sponsor

Piotr Pasik

East Lansing, Michigan

ME Faculty Advisor

Dr. Ahmed Naguib

MSU Adaptive Sports & Recreation Club: Sled Hockey Transfer Platform

The MSU Adaptive Sports & Recreation Club, established in 2014, operates as a Registered Student Organization. It serves as a no-cost program to MSU students, employees, alumni, and the Greater Lansing community. The club’s purpose is to provide an inclusive environment for athletes with physical disabilities, able- bodied volunteers, and academic project personnel. Through sports, the program fosters a community where individuals with physical disabilities and volunteers can come together. The primary objective is to challenge societal stereotypes and personal perceptions about disability while promoting both physical and personal health by ensuring consistent access to a wide range of quality wheelchairs and adaptive sports opportunities. Embracing a self-determining approach, the program prioritizes athlete autonomy, competence, and relatedness to build self-effiency in sports and physical activity, skills that can extend to other areas of life.

Our project is to enhance the Sled Hockey Transfer Platform by concentrating on refining aspects such as safety and user independence. There were some shortcomings regarding safety features in the initial design prompting our team to prioritize and implement improvements. Additionally, we recognized the significance of ensuring that the device could be utilized independently by the user. Our efforts centered around the augmentation and optimization of elements within the platform, striving to create a solution that not only prioritizes safety, but also empowers users to operate the device autonomously. Through thoughtful additions and improvements, our goal is to enhance the overall user experience and contribute to the accessibility and self-sufficiency of individuals utilizing the Sled Hockey Transfer Platform.

Michigan State University

Team Members

(left to right)

Danny Drennan

Livonia, Michigan

Alexa Garavaglia

Clinton Township, Michigan

Arjun Patel

Hoffman Estates, Illinois

Alayna Celestini

Macomb, Michigan

Keegan Sclabassi

Shelby Township, Michigan

MSU Adaptive Sports & Recreation Club

Project Sponsor

Piotr Pasik

East Lansing, Michigan

ME Faculty Advisor

Dr. Giles Brereton

MSU Adaptive Sports & Recreation Club: Inclusive Sports Wheelchair

The MSU Adaptive Sports & Recreations Club was first established in 2014 by Piotr Pasik. Its goal is to promote health, social, and psychological benefits of exercise and activity to individuals with physical disabilities. The club organizes numerous sports and events including wheelchair hockey, tennis, basketball, track, and hand-cycling. It creates a space where athletes with physical disabilities and able-bodied volunteers can work together to create a community of peers that serves to eradicate negative stereotypes by highlighting the abilities of individuals with physical disabilities. Through various grants and funding, the club can purchase sports wheelchairs, equipment, and funding for engineering projects.

The Adaptive Sports Program has worked with the College of Engineering since 2016 to develop various devices and modifications to support the organization and its athletes. With the help of College of Engineering design teams, this project is now in its tenth design phase. The goal of the project was to develop a modified wheelchair to accommodate users with limited mobility. The specific individual has muscle asymmetry that is more pronounced on his left side, preventing him from participating in a standard sports wheelchair. The task was to create a chair that can be propelled and steered using the user’s right leg and arm. This specific design iteration focused on a steering system that still leaves the user’s dominant hand free for sport participation and equipment. Additional desired features included increased durability of the propulsion method, reverse propulsion, and safety and comfort of the user. The project was created with a specific user in mind and prioritized his specific requirements and accommodations for a seamless participation during various sporting events.

Michigan State University

Team Members (left to right)

Aliza Opolka

Fowlerville, Michigan

Kate Nolan

Canton, Michigan

Charlie Meilinger

Beverly Hills, Michigan

Vedi Patel

Canton, Michigan

Jenni Aubin

Johnston, Rhode Island

MSU Adaptive Sports & Recreation Club

Project Sponsor

Piotr Pasik

East Lansing, Michigan

ME Faculty Advisor

Dr. Neil Wright

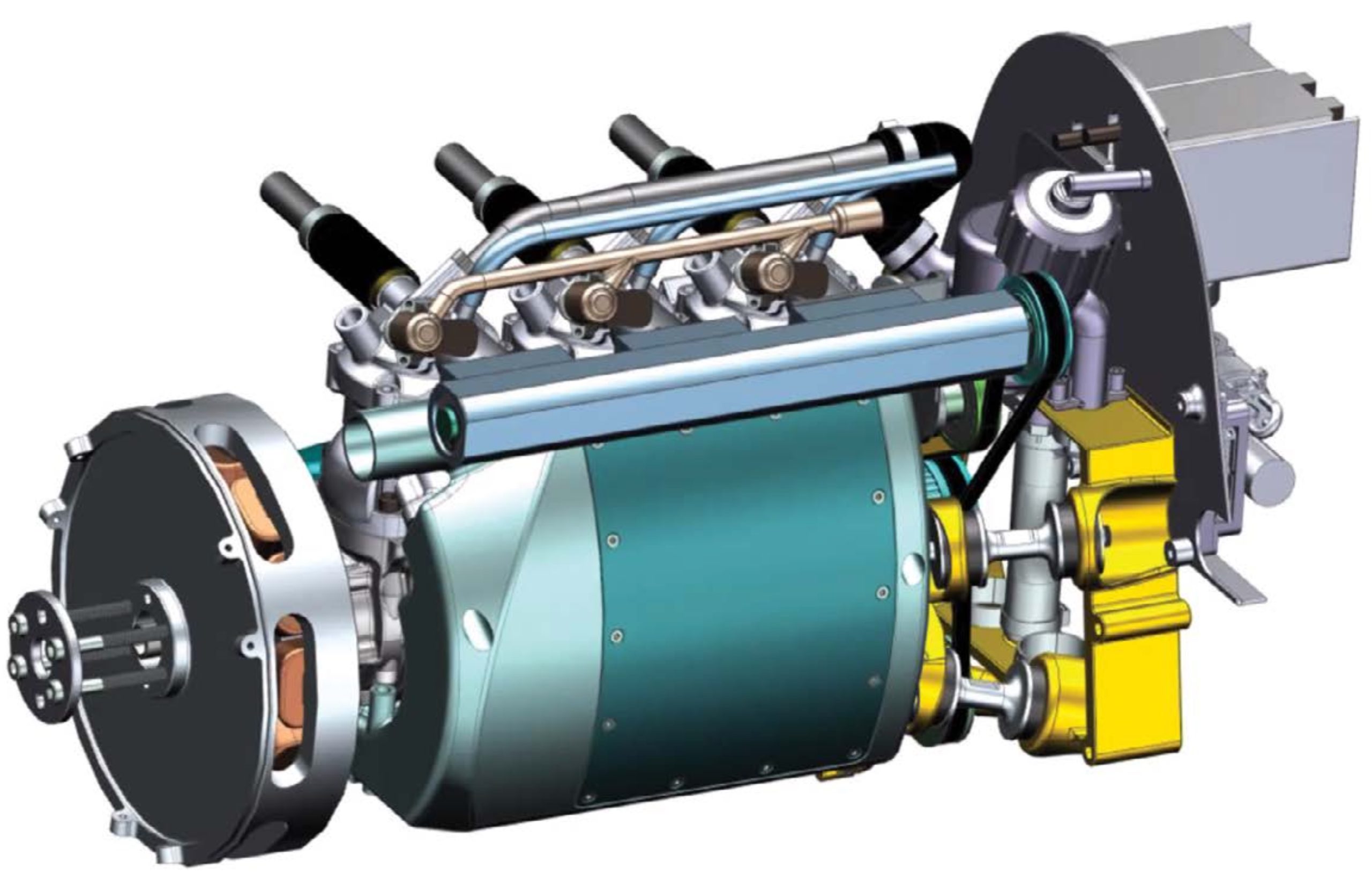

MSU Department of Mechanical Engineering: Design of a Jetfire Two-Stroke IC Engine Rotary Valve

A faculty member from the MSU Department of Mechanical Engineering has pioneered a patented method to activate Turbulent Jet Ignition (TJI) using a discrete unit cartridge. This approach has been licensed to Jetfire Power, LLC for commercialization. Thanks to its revolutionary pre-chamber air control, Jetfire can initiate combustion in highly diluted stoichiometric mixtures, even under intense compression. The combustion process adheres to stoichiometry, facilitating the use of a standard 3-way catalyst for after-treatment. This combustion system accommodates both liquid and gaseous fuels. Notably, the cartridge is constructed from industry-standard components, ensuring smooth integration into an engine’s cylinder head. Jetfire Power, LLC has partnered with Cobra-Aero, Hillsdale, Michigan to apply the Jetfire technology to two-stroke engines.

Our team dedicated efforts to assess various rotary valve systems previously attempted that are best suited for application to a high RPM two-stroke Jetfire engine. Rotary valves hold promise for a more streamlined and lightweight cylinder head design as they rotate at half engine speed (or one quarter), mitigating inertia forces associated with reciprocating valve mechanisms. This characteristic enables higher engine speeds and the potential for increased engine power.

Michigan State University

Team Members (left to right)

Kevin Schultz

Ann Arbor, Michigan

Sydney Kelly

Bartlett, Illinois

Elise Delikat

Rochester, Michigan

Abby Pankey

Rochester, Michigan

Jordan Robinson

Flat Rock, Michigan

MSU Department of Mechanical Engineering

Project Sponsor

Harold Schock

East Lansing, Michigan

ME Faculty Advisor

Dr. Harold Schock

Toyota Motor North America: Vehicle Frunk Usability and Quick Latch Design

Toyota Motor North America, a leading innovator in the automotive industry, has consistently demonstrated a commitment to advancing technology and sustainability in the realm of Battery Electric Vehicles (BEVs). Known for their pioneering efforts in vehicle safety, efficiency, and design, they have embarked on a mission to revolutionize the BEV market. Their latest initiative focused on enhancing the functionality and safety of BEVs, particularly in the development of a front storage area, commonly referred to as the ‘Frunk.’ This project aligns with their long-standing tradition of pushing boundaries in automotive engineering and design, offering a glimpse into the future of electric vehicles.

Our recently concluded project successfully redefined the front storage utility of Battery Electric Vehicles by designing innovative quick latching systems. Through intensive benchmarking and a diligent design process, we engineered several prototypes that boast high-strength hold, low-profile aesthetics, and ease of operation. Our designs adhered strictly to safety regulations, including the Pedestrian GTR head injury criterion, UN-R17: Cargo retention, and ISO-DIN75410-02: Lashing hook. We established a methodical strategy for selecting the best design, supported by comprehensive CAE simulations and a series of meticulously crafted experiments intended for Toyota’s advanced evaluation labs in Ann Arbor and Saline, Michigan. The project’s results are instrumental, offering Toyota a strategic direction for developing versatile Frunk accessories and demonstrating our team’s adeptness in mechanics, dynamics, and materials science, all while maintaining intellectual property integrity.

Michigan State University

Team Members (left to right)

Logan Jacobson

Rochester, Michigan

Daniel Carrillo- Solis

Detroit, Michigan

Deniz Farmaka

Izmir, Turkey

Abdallah Hamad

Brighton, Michigan

Karem Algarash

Hamtramck, Michigan

Toyota Motor North America

Project Sponsors

Peter Khouphongsy

Ann Arbor, Michigan

Aaron Steinhilb

Ann Arbor, Michigan

ME Faculty Advisor

Dr. Rebecca Anthony

MSU Solar Racing Team: Solar Car Hub Motor Housing Design

The MSU Solar Racing Team (SRT) is a student-led organization that was founded 24 years ago. Since then, the team has been competitively designing and racing high-tech, solar-powered vehicles against other colleges and universities with the American Solar Challenge (ASC). The Innovators Educational Foundation (IEF) hosts the American Solar Challenge with the goal of fostering educational excellence and creative engineering. Driven by camaraderie and collaboration, the ASC advocates for the imaginative integration of technical and scientific expertise across a diverse spectrum of engaging disciplines.

The primary objective of this project was to improve upon the existing motor housing design of the current build. This involved implementing a cooling system for the housing, simplifying the current design, and optimizing the overall cost for machining and assembly. Required knowledge included NX, Ansys Finite Element Analysis, GT-POWER, and general manufacturing skills. Emphasis was placed on streamlining the manufacturing process by improving efficiency and increasing simplicity of the design. The design had to align with the professional standards set by the ASC, along with meeting the proper guidelines for consistency and safety. Additional requirements included an aesthetically pleasing final assembly that sported an MSU SRT logo.

Michigan State University

Team Members (left to right)

Reagan Ferschweiler

Lyndhurst, New Jersey

Jake Gilman

Lansing, Michigan

Benjamin Delduca

Dexter, Michigan

Evan Rushbrook

Dexter, Michigan

Jacob Kunka

Peoria, Illinois

MSU Solar Racing Team

Project Sponsors

Rachel Schenck

East Lansing, Michigan

Aditya Swarnkar

East Lansing, Michigan

ME Faculty Advisor

Dr. Guoming Zhu

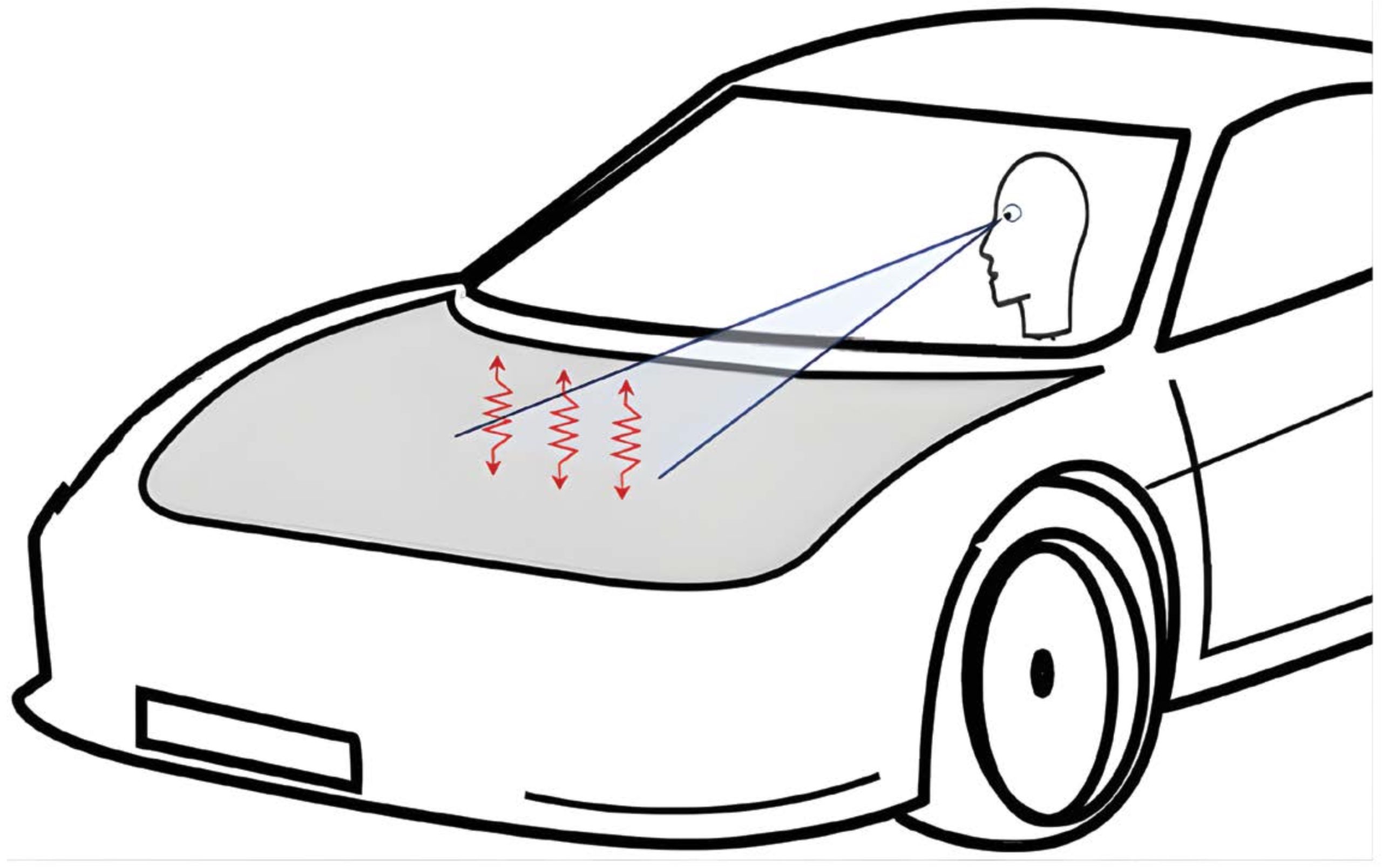

Toyota Motor North America: Automotive Engine Hood Vibration Design

The performance division within Toyota’s Research and Development pillar is responsible for predicting and validating design performance to ensure products are reliable and exceed customers’ expectations. Toyota is continuously looking for ways to improve the evaluation and prediction process. Automotive hood design includes a complex balancing of competing design constraints. As mass optimization and lightweighting becomes more common, hood vibration performance and prediction becomes more critical to ensure customer satisfaction.

In this project, we applied empirical analysis to sharpen Toyota’s design accuracy, specifically addressing automotive hood vibration and its impact on consumer satisfaction. We rigorously collected and analyzed data on human eye perception to hood vibration in order to define acceptable performance levels. This empirical approach enabled us to pinpoint essential structural variables that contribute to vibration characteristics. With this foundation, we crafted a predictive model that correlates these structural parameters with vibration behavior. This innovative model significantly boosts Toyota’s predictive precision for upcoming models, optimizing both development and validation phases. Our strategic use of empirical analysis has been crucial in refining vibrational performance prediction, and securing superior hood integrity that resonates with customer expectations.

Michigan State University

Team Members (left to right)

Brenden Shelby

Commerce Township, Michigan

Nicholas Nastovski

Birmingham, Michigan

Tyler Wysocki

Shelby Township, Michigan

Elia Al Abdullatif

Muscat, Oman

Christian Takla

Northville, Michigan

Toyota Motor North America

Project Sponsors

Kyle Dart

Ann Arbor, Michigan

Braden Klish

Ann Arbor, Michigan

Trey Souchock

Ann Arbor, Michigan

ME Faculty Advisor

Dr. Brian Feeny

NASA/Arizona State University: Power Solutions

In October of 2023, NASA and Arizona State University launched humanity’s first mission to a celestial body believed to be primarily composed of metal, rather than rock or ice: an asteroid by the name of 16 Psyche, orbiting the sun between Mars and Jupiter. Previous observations indicate that Psyche could contain metallic remnants of a planetesimal, a building block of planets like our own. Given current limitations on the exploration of the Earth’s core, investigation of Psyche could provide key insights into the formation of the planets in our solar system.

Following the planned completion of the Psyche mission in 2029, future researchers may propose a mission to physically explore the surface of the asteroid. Such a mission would require the development of novel and cost-effective methods to generate energy using the unique properties of Psyche. Our team completed a literature review of existing power solutions used in space exploration. Synthesizing existing methods with data collected about the surface of Psyche, we proposed a system to generate energy in a manner that takes advantage of the operating conditions the device would be exposed to while exploring the asteroid‘s surface.

Michigan State University

Team Members (left to right)

Matthew Bush

Grand Blanc, Michigan

Ian Calandrino

St. Clair Shores, Michigan

Tyler Doral

Sterling Heights, Michigan

Joe Hamouda

Grosse Pointe, Michigan

Lucas Henricks

Birmingham, Michigan

NASA/Arizona State University

Project Sponsor

NASA Psyche Mission

Tempe, Arizona

ME Faculty Advisor

Dr. Giles Brereton

Pratt Miller: FSAE Front Outboard Electric Motor Assembly

For 30 years, Pratt Miller has used the world’s legendary racetracks as technology proving grounds to develop many race programs, including Corvette Racing, the most successful team in the history of the American Le Mans Series. Pratt Miller’s world-renowned motorsports operation has evolved into the innovative, full-service product development company it is today. With over 300 employees, Pratt Miller is proudly serving a global customer base, including those in the motorsports, defense, mobility and innovation industries.

The MSU Formula Racing Team represents Michigan State University’s entry into the Formula SAE collegiate design series, a competition sanctioned by the Society of Automotive Engineers. Formula SAE promotes innovation and education by challenging students to fund, design, manufacture, and race small, open-wheel racecars. Since its inception in 1981, this series has experienced tremendous participant growth, earning the title of the largest engineering competition in the world and currently hosting nine events in seven countries annually. To date, there are nearly 500 teams around the globe.

The goal of this project is to keep Michigan State University competitive by designing, manufacturing, and testing an electrical outboard motor assembly prototype that operates inside 10” OZ magnesium wheels. The process involved creating a design tailored to a specific motor that will be 3D printed to serve as a proof of concept. This approach enabled us to test the feasibility before significant financial investment is made in the motor for its implementation in the vehicle.

Michigan State University

Team Members (left to right)

Cameron Hesano

Lake Orion, Michigan

Rafael Abage

Curitiba, Brazil

Matthew Ajlouny

Troy, Michigan

Anissa Sant

Wixom, Michigan

Ronak Patel

Burr Ridge, Illinois

Pratt Miller

Project Sponsor

Hans Walther

New Hudson, Michigan

ME Faculty Advisor

Dr. Gary Cloud

Michigan AgrAbility: Portable Swarm Trap Lifter

Michigan AgrAbility is an organization that provides services to farmers with disabilities, illnesses, or aging conditions so they can continue participating in the work that they love. In joint partnership with MSU Extension and Easterseals Michigan, they work to research and develop farming tools, equipment, and methods to help with the challenges presented by disability. This group has a profound impact on the agriculture and farming industry by alleviating some of the concerns for farmers and their families by adapting to the physical, emotional, and financial uncertainties that often come with disabilities and chronic health problems. For this project, we worked with Gary Brown, a veteran with a back injury who works as both a beekeeper and a leader of a Heroes to Hives program at his local VFW to teach other veterans beekeeping.

Beekeepers with back, mobility, and upper extremity impairments due to spinal cord injury, amputation, stroke, or military injuries cannot climb ladders to install and remove heavy swarm traps. This problem necessitated the development of a lifting mechanism that could hoist a swarm trap box and eliminate the need for use of a ladder or heavy lifting while installing or uninstalling traps. Significant research was conducted in order to study existing and similar efforts that have been developed for the lifting and transport of swarm traps. To account for the heavy lifting constraint, a transport method was designed to facilitate moving the mechanism to and from the woods. Finally, detailed construction drawings and instructions were created in order to facilitate future fabrication of the device by beekeepers around the nation who would benefit from a disability-friendly swarm trap lifter. A prominent focus was placed on a simple and cost- effective design, as the desire was for the average beekeeper to easily source parts and manufacture this device for themselves.

Michigan State University

Team Members (left to right)

Brandon Roux

Holly, Michigan

Bradley Haskin

South Lyon, Michigan

Amanda Jeffers

Clinton Township, Michigan

Bennett Guensche

Grand Rapids, Michigan

Daniel Staal

Holland, Michigan

Michigan AgrAbility

Project Sponsor

Ned Stoller

Grand Rapids, Michigan

ME Faculty Advisor

Dr. Xinran Xiao

MSU Combat Robotics Team: Combat Robotics Vehicle Design and Development

The MSU Combat Robotics team was started in the fall of 2023. The goal of this group is to create combat robots to enter into competitions. In these tournaments, robots compete in one-on-one battles to see who can inflict the most damage and remain operational.

Our team partnered with the Combat Robotics Team for this project to design, build, and compete with a combat robot. We went through all the stages of development of a combat robot with the intention of completing a robot capable of entering competitions. We designed the robot to compete in the 30-lb weight division. To do this, we had to design our robot to comply with the competition rules and safety regulations. This project included designing the robot’s weapon, drive systems, chassis, weapon drive, and controls for both the drive and the weapon.

After finalizing the design, we ran simulations to identify stress concentrations and redesigned parts to maximize their strength. This included finite element analysis on the weapon, the chassis, and the weapon shaft. When the design was finalized, we were tasked with building the robot. To complete this, we first identified which parts we could manufacture in- house. We had to submit work orders for parts we could not manufacture, such as the weapon, due to the material properties and manufacturing constraints.

Once all the parts were completed and received, we assembled the combat robot and added our electronic control system. All the controllers were calibrated to run the motors at our desired speeds. This system had to be designed so the wiring would not be damaged when impacted.

Our team plans to enter our robot into our first competition after completion of this project.

Michigan State University

Team Members (left to right)

Owen Korff

Canton, Michigan

Ryan Prost

Rochester, Michigan

Nicole Gibbons

Lansing, Michigan

Ellie Clark (Sponsor)

Grand Rapids, Michigan

Ari Bozann

Okemos, Michigan

Ahmed Abboushi

Lansing, Michigan

MSU Combat Robotics Team

Project Sponsor

Ellie Clark

Grand Rapids, Michigan

ME Faculty Advisor

Dr. Elisa Toulson