Adventures in Training with a Purpose: Ambulation Aid – Foot Design

Adventures in Training with a Purpose: Quick-Release Handle Design

Asahi Kasei Plastics North America: Ergonomic Lifting Solution for Packaged Materials

Battleship New Jersey Museum & Memorial: Smoke Simulation from the Stacks

Cleveland-Cliffs, Inc.: OCR Camera Mount for Mill Conveyor System

Cleveland-Cliffs, Inc.- Optimal Character Recognition Camera Mount

Consumers Energy: Advanced Methane Detection Cooling System

Consumers Energy: Gas Leak Detection System Control Panel

EarthSense: Chestnut Harvester

EarthSense: Chestnut Harvester

Flash Steelworks, Inc.: Flash Tubing Lightweight Steel Bike Trailer Design

Flash Steelworks, Inc.: Utility Vehicle Trailer

Heartwood School/Ingham ISD: Adult Ride-on Mobility Car Development

Ingham ISD: Device to Facilitate Self-Installing Foot-Ankle Brace

Ingham ISD: In-School or In-Home Lift Assist Device

Ingham ISD: Portable Posture Assist

Ingham ISD: Portable Ramp for Regular School Bus Use

Ingham ISD: Step Therapy Device for Motor Skills Development

Lacks Enterprises/MSU Formula SAE Racing Team: Formula SAE Composite Wheels

McLaren Engineering: Design Factors Affecting Radiated Noise of an e-Axle Housing

McLaren Engineering: Gear Design for Noise Reduction

Michigan AgrAbility: Self-Propelled Beehive Lifting Mechanism

Michigan Department of Natural Resources: Efficiency of Ice Suppression Systems

MSU Adaptive Sports & Recreation Club: Inclusive Sports Wheelchair

MSU Adaptive Sports & Recreation Club: Increasing Hockey Sled Mobility

MSU Adaptive Sports & Recreation Club: Sled Hockey Transfer Platform: Phase V

MSU Department of Mechanical Engineering: Piston Friction Reduction to Improve Engine Efficiency

MSU Department of Theatre: Counterweight Elevator

MSU Recycling Center: Improved Cart Tipper Design

MSU Recycling Center: Recycling, Debagging and Film Removal

MSU Solar Car Team: Solar Car Body and Chassis Design Prototype

Adventures in Training with a Purpose: Ambulation Aid – Foot Design

Directed Steps is a project centered in confronting mobility issues as part of the Adventures in Training with a Purpose (ATP) program. This program provides support for those who no longer have the benefit of paid rehabilitation. In addition, few facilities are equipped with the level of trained staff and devoted time necessary to develop programs for those in need. ATP tackles these challenges head on, restoring quality of life and improving movement in each individual. Through Adventure, participants are motivated to take a journey that promises challenges, but also brings deep meaning along the way. In Training, the program takes participants through mobility work, strength exercises, and aerobic conditioning to develop the individual’s physical armor. Altogether, participants embark on an adventure of purposeful physical training, creating a fulfilling Purpose for every person who takes on the journey.

The goal of this project was to design and prototype an ambulation aid for a patient undergoing physical rehabilitation for a spinal cord injury. This device compensates for range of motion and strength insufficiencies in the upper and lower extremities to improve their function and the patient’s quality of life. Common injury aids, such as braces and underarm crutches, lack the amount of support necessary for those with chronic conditions and do not provide the opportunity to increase physical ability. To combat these problems, our team designed a spring-loaded forearm crutch with a larger crutch base than employed in traditional crutches. These features help propel forward motion by increasing the kinetic energy utilized during the swing phase in order to improve the patient’s mobility.

Michigan State University

Team Members (left to right)

Will Berlage

Troy, Michigan

Ben Gaynier

Livonia, Michigan

Nina Palazzolo

Berkley, Michigan

Maggie Ritchie

Northville, Michigan

Sophia Swiecki

Northville, Michigan

Adventures in Training with a Purpose

Project Sponsors

Jon Kolb

Wexford, Pennsylvania

McDaragh Minnock

Wexford, Pennsylvania

ME Faculty Advisor

Dr. Seungik Baek

Adventures in Training with a Purpose: Quick-Release Handle Design

Adventures in Training with a Purpose (ATP), located in Pittsburgh, PA, is a nonprofit organization that helps people suffering with chronic pain and disease regain mobility. The organization prioritizes restoring quality of life, improving functional movement, and ultimately regaining independence. Its mission is especially noble considering clients’ serious degrees of injury, need for dedicated one- on-one training, and ATP’s commitment despite insurance coverage rarely supporting long-term rehabilitation.

A quick-release mechanism was designed for use with forearm crutch cuffs. The mechanism allows users to release the cuff from the crutch body in an instant. This is especially important in situations when the user is falling. The quick- release mechanism allows them to free their hands from the crutches, break their fall, and prevent further injury from being tangled within the crutch. ATP clients will finally be able to safely regain independence with crutches that prioritize their safety.

Michigan State University

Team Members (left to right)

Delano Dalfonsi

Dearborn, Michigan

Brian Hanton

Allentown, Pennsylvania

Lila Ninotti

Clarkston, Michigan

Vanessa Pariso

Oxford, Michigan

Joshua Woodford

Okemos, Michigan

Adventures in Training with a Purpose

Project Sponsors

Jon Kolb

Wexford, Pennsylvania

McDaragh Minnock

Wexford, Pennsylvania

ME Faculty Advisor

Dr. Seungik Baek

Asahi Kasei Plastics North America: Ergonomic Lifting Solution for Packaged Materials

Asahi Kasei Plastics is a leader in plastics technology and innovation. As a major supplier for the automotive industry, on average 11 pounds of Asahi Kasei plastics can be found in cars today. Other segments also contain Asahi Kasei plastics, including pool and spa, industrial, furniture, housing, construction, and more. Workplace safety is a high priority, and Asahi Kasei is constantly looking for ways to improve manufacturing operations and increase safety. Currently, in the Fowlerville manufacturing facility an operator must manually lift 25kg paper sacks of raw material from a pallet to the blender where the material is processed. The repetitive stress of manually moving these heavy bags of raw material poses a potential safety issue for back injuries.

The objective of this project was to design and implement an ergonomic solution to eliminate the task of manually lifting paper sacks of raw materials from the pallet to the blender. The targeted workspace had height and space constraints, and the solution needed to accommodate multiple pallet locations and variable bag sizes and weights. Our solution consists of a powered mechanism to lift the paper sacks of raw material, allowing an operator to direct the bags from the pallet to the blender with little effort. The solution is expected to improve the efficiency and throughput of production by successfully transporting the packaged materials undamaged while decreasing the instance of ergonomic injuries.

Michigan State University

Team Members (left to right)

Rohan Challa

Novi, Michigan

Rhett Pimentel

Powell, Wyoming

Emma Clawson

Grand Rapids, Michigan

Katharine Walters

Dearborn, Michigan

Garrett Ruhala

Almont, Michigan

Elijah Pickard

Marquette, Michigan

Asahi Kasei Plastics North America

Project Sponsors

Roy Travis

Fowlerville, Michigan

ME Faculty Advisor

Dr. Giles Brereton

Battleship New Jersey Museum & Memorial: Smoke Simulation from the Stacks

The Battleship New Jersey is the longest, fastest, most decorated battleship in history, serving in WWII, the Korean War, the Vietnam War, and the Persian Gulf. In 2001, she became a museum in Camden, New Jersey. The Battleship New Jersey Museum & Memorial have worked to preserve and restore the USS New Jersey to keep the memories of those who came before us alive. Repairing the ship’s horn and search radar antenna were among the projects completed to bring the ship to its former glory.

Moving forward, the Battleship New Jersey Museum & Memorial is working to simulate smoke from one of the ship’s smokestacks. Initial experimentation with a commercial fog machine was used to generate a theatrical smoke effect. It was found to be a demanding system that required a lot of upkeep and can be costly with the constant purchase of fog machine fluid. A more permanent system, dependent on water and electricity, was designed to lower the cost and provide visible simulated smoke efficiently without any structural changes to the ship. This mechanism has the ability to handle New Jersey winters and can be shut on and off when desired. If successful, this would be the first naval museum ship to simulate smoke and appear active.

Michigan State University

Team Members (left to right)

Sarh Al Bawardi

Khobar, Saudi Arabia

Drake Deming

Brighton, Michigan

Stacy Fakhoury

East Lansing, Michigan

Alex Kriese

Farmington Hills, Michigan

Hailey Minton

Clarkston, Michigan

Battleship New Jersey Museum & Memorial

Project Sponsors

Clark Perks

Camden, New Jersey

ME Faculty Advisor

Dr. Indrek Wichman

Cleveland-Cliffs, Inc.: OCR Camera Mount for Mill Conveyor System

Since its founding in 1887, Cleveland-Cliffs now has 68 operating facilities and is the largest flat-rolled steel company in North America. The company is vertically integrated and therefore is responsible for the entire steel production process. This includes the mining of raw materials and the refinement of high-end steel products for markets, including but not limited to, automotive, appliance, aviation, industrial, and construction. Cleveland-Cliffs is considered an advanced manufacturing and engineering service company and provides high quality tool building capabilities such as hot and cold stamping and has continually proven to be a leader in die design.

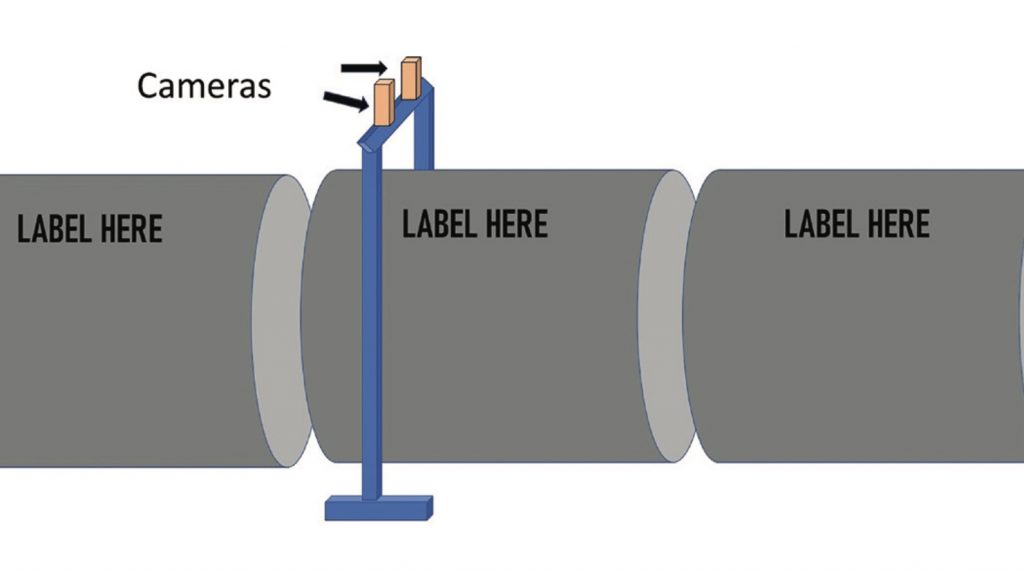

A majority of their sales, however, are steel coils, which can weigh anywhere between 50,000 to 80,000 pounds. In order to remove any impurities on the outside of the steel, the steel coils go through a pickle line in which they are loaded onto a conveyor belt in a very specific order and then run through a bathtub of hydraulic acid. In order to avoid missing a coil or loading the wrong coil onto the conveyor belt, two IV3-500CA Optimal Character Recognition (OCR) cameras are used to read the labels. The goal of this project was to construct a robust mount capable of holding these cameras so that the labels of the steel rolls could be processed. Ease of fabrication, how much space would be taken up, and the ability to readjust the camera were all factors taken into consideration during the design.

Michigan State University

Team Members (left to right)

Jacob Pawloske

Waterford, Michigan

Max Kempisty

South Lyon, Michigan

Jack Hasselbring

Rochester Hills, Michigan

Noah Crusoe

Rochester Hills, Michigan

Jacob Grimmer

Northville, Michigan

Kirk Maibach

Northville, Michigan

Cleveland-Cliffs, Inc.

Project Sponsors

Lauren Hart

Burns Harbor, Indiana

ME Faculty Advisor

Dr. Lik-Chuan Lee

Cleveland-Cliffs, Inc.- Optimal Character Recognition Camera Mount

Cleveland-Cliffs has been traditionally recognized as the largest and oldest independent iron ore mining company in the United States. In 2020 with the acquisition of two prominent steel companies, Cleveland-Cliffs conducted a transformation that will keep the company thriving for the next century. Today, they are now the largest flat-rolled steel company and the largest iron ore pellet producer in North America. The Company is vertically integrated from mined raw materials, direct reduced iron, and ferrous scrap to primary steelmaking and downstream finishing, stamping, tooling, and tubing and downstream with hot and cold stamping of steel parts and components. They have the unique advantage of being self-sufficient with production of the raw materials for their steelmaking operations.

Due to the extreme volume of flat-rolled steel, it is important for Cleveland-Cliffs to create increasingly efficient production methods to save money and time. Our group was assigned to aid in efficient production by creating a stationary OCR (optical character recognition) system. The flat-rolled steel (right) has identification codes that are crucial for identifying the placing order. Each coil has a different treatment process. They also have different metallic properties and misplacement of the coils can cost no less than $50,000. These coils are placed by hand, which can lead to error. Our mission was to design a camera mounting station that can identify if there is a misorder. The system is a gantry with two camera mounts hanging over the conveyor (right), which will send the coil number images to personnel managing the plant. This will allow the plant to save time and money by ensuring the order of the coils is correct every single time.

Michigan State University

Team Members (left to right)

Blake Mallamo

Chesterfield, Michigan

McKyle Stanfield

Mason, Michigan

Elias Rodriguez

Mason, Michigan

Connor West

Hartland, Michigan

Willis Wuebben

Livonia, Michigan

Brendan Macdonald

Traverse City, Michigan

Cleveland-Cliffs, Inc.

Project Sponsors

Lauren Hart

Burns Harbor, Indiana

ME Faculty Advisor

Dr. Tong Gao

Consumers Energy: Advanced Methane Detection Cooling System

Consumers Energy is one of Michigan’s largest providers of natural gas and electricity. Its robust natural gas infrastructure includes 30,000 miles of natural gas pipeline, through which it delivers more than 350 billion cubic feet of natural gas to customers every year. In addition, the company maintains pressure-regulating stations and underground storage facilities to ensure that gas can be delivered safely and efficiently to people across the state. Consumers Energy is committed to reducing greenhouse gas emissions and plans to reduce methane emissions by 80% by 2030. To this end, Consumers Energy has begun using Picarro’s methane detection technology to identify and correct emissions.

The main goal of this project is to develop a cooling device for the advanced methane detection system that Picarro has produced. Consumers Energy has teamed up with it in detecting methane emissions and pinpointing areas of interest for methane investigations. The main issue is overheating of the system causing premature battery drainage during the summer months when the car’s smart idle system shuts down and the internal cooling fans are left to run on reduced battery capacity. This leads to an irregular shutdown process and a complicated reboot process. To account for this error, our team has developed a product that will take in real time temperature of the system and begin cooling once the area of interest has surpassed the battery efficiency threshold.

Michigan State University

Team Members (left to right)

Paige Brechtelsbauer

Rochester, Michigan

Jacob Campion

Lake Orion, Michigan

Thomas Jennett

Gladwin, Michigan

Alec LeVasseur

White Lake, Michigan

Zac Seeds

Lake Orion, Michigan

Consumers Energy

Project Sponsors

Stephanie Pierce

Jackson, Michigan

ME Faculty Advisor

Dr. Neil Wright

Consumers Energy: Gas Leak Detection System Control Panel

Consumers Energy was founded in 1886 in Jackson, Michigan. It is one of the leaders in providing electricity and natural gas to over 6 million Michigan residents. The main goal of the company is to provide reliable and safe energy to the people of Michigan while putting an emphasis on increasing the use of clean, renewable energy to minimize Michigan’s carbon footprint leading to a cleaner world. Consumers Energy generates 5,885 Megawatts of generating capacity to over 87,097 miles of electrical lines. On top of this, it provides 27,958 miles of pipeline for natural gas distribution.

To make sure Consumers Energy’s pipelines are not experiencing defects, it must continually perform routine checks. One of the ways it checked for faults was to introduce an air analyzer into two of its instrumented cars. The air analyzer was used to determine if there was a methane leak by comparing controlled samples of air concentrations to the air the system was intaking when it drove by the pipelines. The analyzer was connected to a tablet or phone to allow the driver to view the air quality in real time.

The goal of this project was to create a more stable tablet/phone mount that the driver can position to easily view to receive updates about the air quality. In addition to creating a more stable mount, LEDs were added to inform the driver if there is internet connection. This improvement allows the driver to know if the data are being processed and uploaded to Consumers Energy’s database in real time. With the newly implemented mount, the overall work quality for the driver has improved.

Michigan State University

Team Members (left to right)

Garrett Watson

Macomb, Michigan

Jared Ludacka

Lisle, Illinois

Quentin Wade

Dexter, Michigan

Adam Bresson

Northville, Michigan

Hernan Brarda

Novi, Michigan

Justin Kinville

Lansing, Michigan

Consumers Energy

Project Sponsors

Stephanie Pierce

Jackson, Michigan

ME Faculty Advisor

Dr. Abraham Engeda

EarthSense: Chestnut Harvester

EarthSense is a top developer of autonomous robots that specializes in biosystems and agriculture. Its ultracompact robots are easy to use on tablet apps with advanced data- collection technology. These technologies include high-definition cameras, accurate positioning systems, fast perception, and long- distance control. The navigation system on these robots has been tested on over 200,000 corn plots. These autonomous vehicles typically drive on fields in swarms. This allows their 3-hour battery life to be met as large fields are swept by multiple vehicles. EarthSense’s innovative designs of autonomous vehicles have created new opportunities and better observation and control of the agriculture industry.

In collaboration with EarthSense, the Michigan State Biosystems and Agricultural Engineering department tasked our team to create a system that collects variable sized chestnuts off the ground of a biologically diverse and cluttered orchard floor using autonomous ground vehicles as a base platform. An assumption for this project was that the vehicle already had a chestnut detection system, and the vehicle would drive to that location to collect the chestnuts. The vehicle used in this project was the TerraMax, which is being designed to fertilize fields. This autonomous vehicle, at roughly 4x4x3 feet, was created to have multiple ways to interface agricultural technology to the hull of the machine. The machine is capable of holding up to 2000 lbs, which gave significant design freedom for both the collector and collector bin. Our project was designed to attach to the hull of the vehicle and was programmed to pick up a chestnut and deliver it into a collection system. The TerraMax was still in testing and early development, so we were not able to interface with the actual vehicle. We simulated the structure of the vehicle by building a mule out of wood to interface our project for reference.

Michigan State University

Team Members (left to right)

Jax Prusakiewicz

Gaylord, Michigan

Tommy Pang

Taipei, Taiwan

Sam Pellinen

Racine, Wisconsin

Nick Occhiuto

Lansing, Michigan

Ryan Koschay

Grand Ledge, Michigan

John Gregor

Harrison Township, Michigan

EarthSense

Project Sponsors

Daniel Guyer

East Lansing, Michigan

Chinmay Soman

Champaign, Illinois

ME Faculty Advisor

Dr. Ronald Averill

EarthSense: Chestnut Harvester

Earth Sense is a company that specializes in the production of unmanned ground vehicles (UGVs), mainly for the purpose of farming and agricultural needs. Their UGVs have the capability to collect data about a field of crops simply by navigating through it and scanning plants. Using the data it collects, it is able to analyze and give feedback on the state of the crops, allowing for more in-depth management of a field. Its innovative design allows the UGV to traverse many different terrains, making it useful in many types of fields. The company is hoping to soon release a new vehicle that can not only scan plants but also collect ripe crops, store them onboard the vehicle, and bring these crops to a collection location.

The chestnut harvester was a project that aimed to create a subsystem for this new EarthSense UGV that allows it to harvest chestnuts. Often chestnut orchards are too large for handpicking, but too small for large machinery to harvest the nuts. With the chestnut harvester, many UGVs will be able to traverse and pick up the nuts much faster than it would take humans to handpick them. The subsystem was designed with the idea that it has already detected chestnuts on the ground and that there may be environmental variations such as twigs and burrs that make them difficult to pick up. It has a robotic arm attachment, equipped with an end effector for picking up nuts. The articulating arm allows it to place the nut in the UGV’s onboard storage. Although this project focused on chestnuts, this concept has immense scope in the agricultural industry and can have varied applications in other types of fields.

Michigan State University

Team Members (left to right)

Devynash Agrawal

Bangalore, India

Jessica Gorthro

New Baltimore, Michigan

Kace Krauss

Perry, Michigan

Xichen Zhu

Zhejiang, China

Srujan Gubbi

Commerce Township, Michigan

Samir Hussain

Bloomfield Hills, Michigan

EarthSense

Project Sponsors

Daniel Guyer

East Lansing, Michigan

Chinmay Soman

Champaign, Illinois

ME Faculty Advisor

Dr. Ronald Averill

Flash Steelworks, Inc.: Flash Tubing Lightweight Steel Bike Trailer Design

Flash Steelworks Inc, headquartered in Washington, Michigan, is a research and development firm specializing in the development of advanced high- strength steel. The U.S. Department of Energy has called Flash Steelworks, Inc. “the world’s leading performing material for lighter and stronger vehicles.” The technique used is a patented, novel heat-treating methodology in which steel is heated from room temperature to 1000 degrees Celsius in seconds and immediately quenched upon reaching peak temperature. Using this high-strength steel, Flash Steelworks, Inc. has been able to fill the strength requirements of existing systems while reducing the weight significantly. The ability to reduce the weight of products while maintaining the structural integrity has many applications.

Our team was asked to create a new hitch-mounted bike rack design using Flash Steelworks, Inc. steel. Existing bike racks are heavy, expensive, and difficult to use. Some bike racks can even cause damage to the frame of the mounted bike and have parts that tend to wear quickly with use. These issues are required to be addressed in a new design. Due to the strength of the steel, the wall thickness used to construct the rack was lower than on existing products, driving the weight down. By using a simple design, thus limiting the number of parts, the team attempted to reduce the price in relation to current market standards. A successful design will produce a bike rack that is lightweight, easy to use, and available at a lower cost.

Michigan State University

Team Members (left to right)

Sean Colling

Berkley, Michigan

Zach Vander Stel

Hudsonville, Michigan

Olivia Dario

Plymouth, Michigan

Cooper Strebeck

Stevensville, Michigan

Ian Beshears

Stevensville, Michigan

Hanna Gehrke

Shelby Township, Michigan

Flash Steelworks, Inc.

Project Sponsors

Gary Cola

Washington, Michigan

ME Faculty Advisor

Dr. Xiran Xiao

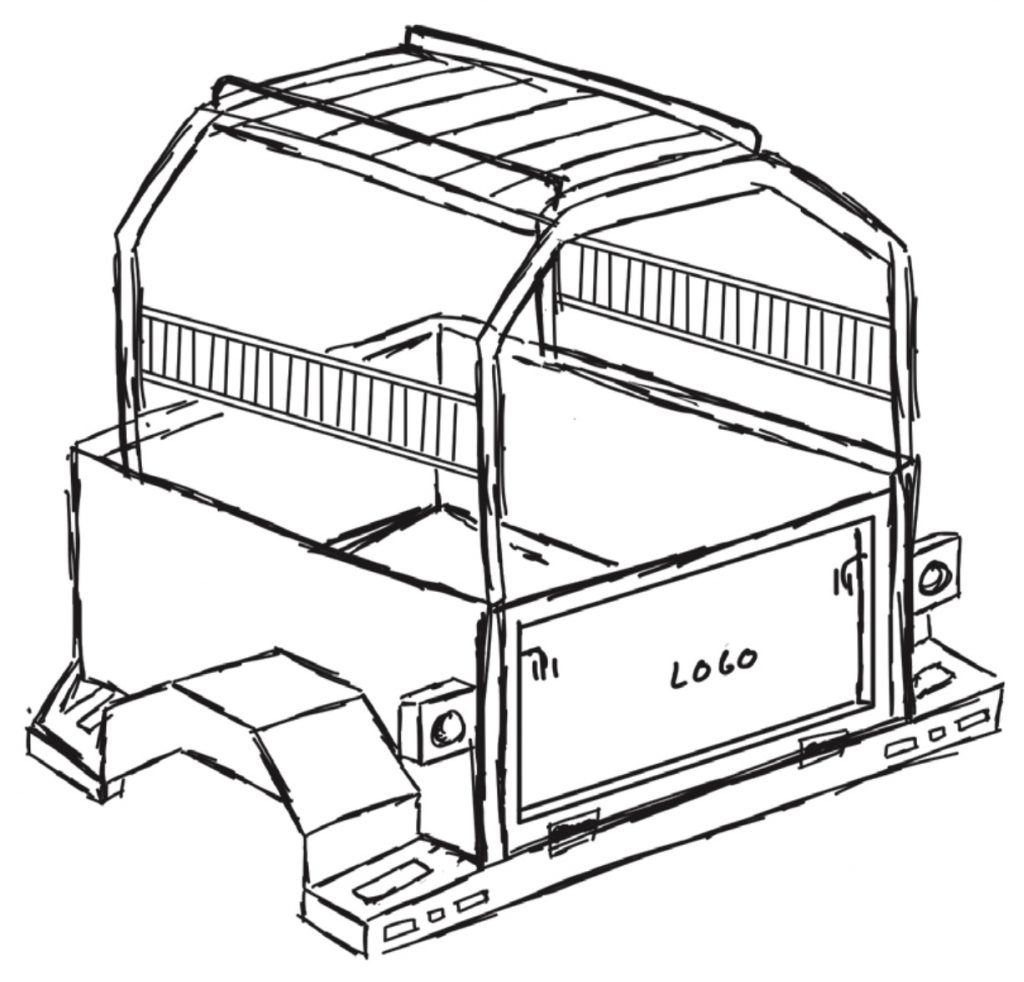

Flash Steelworks, Inc.: Utility Vehicle Trailer

Flash Steelworks, Inc. developed a revolutionary thermal processing cycle that is capable of strengthening steel to an exceptional level. This process allows the steel to have a high level of strength, formability, and weldability for a lower cost than existing ultra-high strength steels. Flash Ultra 600 Armor plate is made using this process This allows it to be lighter than other armor plate options while also being one of the only weldable ultra-hard armor plate options on the market.

Our team used high strength steel tubing, made using Flash Steelworks’ revolutionary thermal processing cycle, to design and build a high strength and lightweight off- road utility trailer. It is able to be pulled behind a truck or a side by side. The trailer has a tube chassis and is able to carry anything from off-road gear and a rooftop tent to a lawn tractor. The suspension we designed is an axle-less, independent suspension. It also has aluminum diamond plating to help keep mud and water off of the cargo. We designed it with ease of manufacture in mind. This helped the build process to be smoother and quicker.

Michigan State University

Team Members (left to right)

Ty Ebling

Traverse City, Michigan

Tyler Lim

Okemos, Michigan

Connor Bragg

Bel Air, Maryland

Danny Mondrusov

Farmington Hills, Michigan

Henrique Pio

Commerce Twp, Michigan

David Schulte

White Lake, Michigan

Flash Steelworks, Inc.

Project Sponsors

Gary Cola

Washington, Michigan

ME Faculty Advisor

Dr. Thomas Pence

Heartwood School/Ingham ISD: Adult Ride-on Mobility Car Development

The Adult Ride-on Mobility Car was developed by our team for Heartwood School. Heartwood serves students with moderate to severe cognitive impairments and disorders. These students can range between ages 3 to 26. Programs at Heartwood help these students to achieve their greatest potential via a safe, educational, and supportive program.

The Adult Ride-on Mobility Car developed by our team for Heartwood School was designed to be a vehicle that both young and old students could use to develop better motor skills, coordination, and muscle strength. Our team needed to design and create a vehicle that could be moved by the users’ feet or an assistant’s hands via a handle. The key elements addressed in this project were a strong body framework, seatbelt, handle system, and interactive elements for the students. In addition, these components needed to be safe and capable of withstanding significant weight and bumps/impacts. We kept in mind that students of vastly varying size and capability should be able to use the Mobility Car. A caregiver, if needed, would be able to push the vehicle with the student secured. Alternatively, a student with more physical capability could use their feet to maneuver it. Research, design, CAD modeling, fabrication, and testing was done to produce the best possible result, a mobility car that the user enjoys using.

Michigan State University

Team Members (left to right)

Logan Maak

Rochester, Michigan

Joe Fantin

Rochester, Michigan

Martin Stokes

South Lyon, Michigan

Adam Van Gieson

Brighton, Michigan

Michael Trajkovski

South Lyon, Michigan

Ingham ISD

Project Sponsors

Heather Vogt-Frechette

Mason, Michigan

ME Faculty Advisor

Dr. Norbert Mueller

Ingham ISD: Device to Facilitate Self-Installing Foot-Ankle Brace

Ingham Intermediate School District is a regional educational service agency that works with 12 schools within seven counties, providing support for preschoolers, students with special needs, their families, and educators. It collaborates with these schools through hundreds of programs and services to give every student a chance to succeed as a learner. One group of students they work with are students who require physical therapy due to physical limitation. Ingham ISD therapists work with students in the local districts to help them achieve independence with functional tasks

One such case can be seen from the project Ingham ISD had tasked our team. They had asked us to develop and create a device that would hold an ankle foot orthosis (AFO) steady while users are attaching the brace to themselves. The project was assigned to help one particular student who had developed Rapid Onset Dystonia Parkinsonism. This device allows him to safely insert his foot into his brace and use the other side of his body to secure the brace himself. At the request of Ingham ISD, the device has been designed such that it can be used universally by many users with a multitude of conditions that would require them to use an AFO. This required the device to have an adjustable/adaptable mechanism capable of comfortably and efficiently securing the AFO of the subject. This was accomplished through the scissor jack base, adjustable Brannock-like device, and 3-dimensional scanned back for comfort.

Michigan State University

Team Members (left to right)

Logan Maak

Rochester, Michigan

Joe Fantin

Rochester, Michigan

Martin Stokes

South Lyon, Michigan

Adam Van Gieson

Brighton, Michigan

Michael Trajkovski

South Lyon, Michigan

Ingham ISD

Project Sponsors

Heather Vogt-Frechette

Mason, Michigan

ME Faculty Advisor

Dr. Norbert Mueller

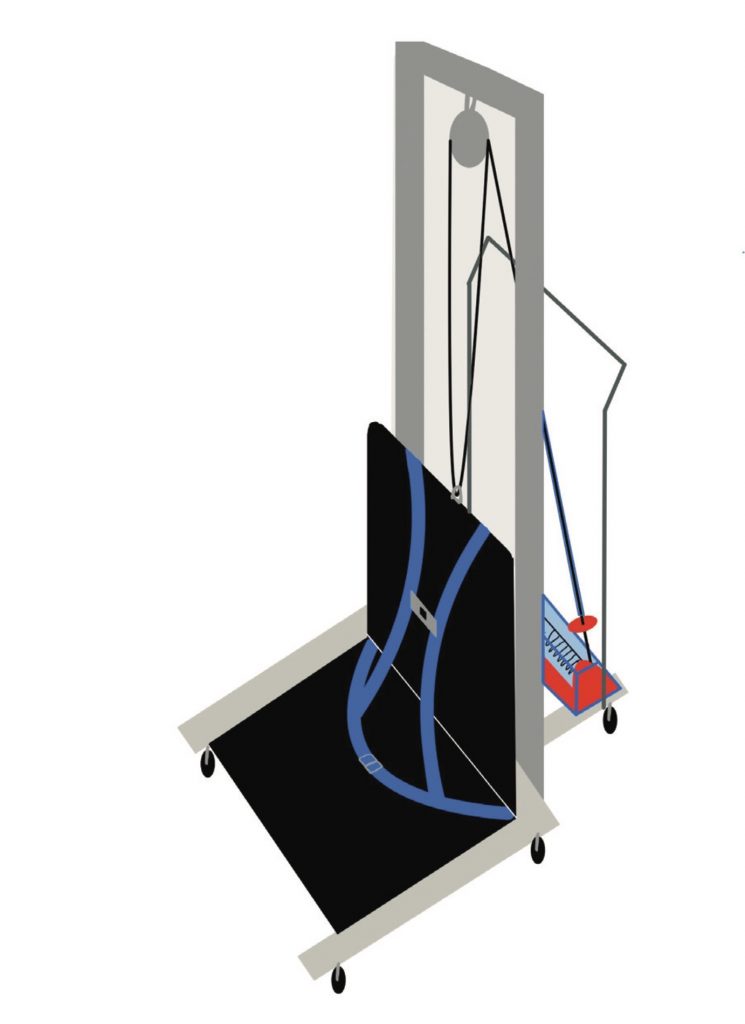

Ingham ISD: In-School or In-Home Lift Assist Device

The Ingham Intermediate School District (Ingham ISD) is a shared community of schools in the surrounding Lansing area that strives to fill learning gaps and enhance education for all students. Ingham ISD has worked with the Mechanical Engineering Department at Michigan State University for a number of semesters to design an assistive lifting device for students with disabilities.

The goal of this project was to add safety advancements to a partially completed assistive lift so that it may be used with students from Ingham ISD to improve their quality of life. The lift was originally designed for a specific student, but all safety advancements modified the lift to be able to be used for students with a variety of disabilities. The device safely lifts students weighing up to 150 pounds from floor level to a standard seated level of 30 inches off the ground with the ability to stop at any height in between. The lift is operated by a remote control used by a single caregiver, instead of manually lifting the student using multiple caregivers. With added safety improvements the lift will be able to be used by a variety of students to meet their needs. Added to the device was a seatbelt covering both the student’s waist and upper body, which can be adjusted to the student’s specific needs, as well as technology to prevent the lift from exceeding 30 inches, thus preventing failure and reducing the risk of injury for students in the lift. The addition of collapsible handles allows the device to easily relocate students around a school or home and store the device in minimal space when not in use. Finally, the device was complete with extra stability to prevent tipping when the lift is operating and covers for the cables and machinery to prevent student and operator injury. The lifting device is compact enough to travel or be stored around a school or home. Overall, the ability to be easily lifted to a variety of heights improves students’ quality of lives allowing them to better interact inside the classroom and in their home.

Michigan State University

Team Members (left to right)

Emma Todd

Grand Ledge, Michigan

Jack Lambrix

Monroe, Michigan

Madeline Stump

Lansing, Michigan

Nathaniel Clinger

Grand Rapids, Michigan

Karli Deutscher

Huntsville, Alabama

Ingham ISD

Project Sponsors

Joanne Janicki

Mason, Michigan

ME Faculty Advisor

Dr. Siva Nadimpalli

Ingham ISD: Portable Posture Assist

Ingham Intermediate School District is a regional education service agency serving more than 44,000 students, including special needs children. Many special needs children require extra support for proper posture due to weakness, impaired balance, and gross motor delays; but they also want a chair that looks like those of their peers and not like a piece of medical equipment. When kids are not supported correctly, they use a lot of their focus and energy to remain upright. These students learn best when they are supported properly, and their brains can focus on what is being presented.

Our task was to adapt an existing chair to fit these needs. Our team created a portable support system to aid the students in maintaining this proper posture. This system includes armrests, a lower arch support and a foot support to perpetuate the ideal 90, 90, 90 angles of their hips, knees, and arms while maintaining a neutral head position. The new arm rests and foot support are adjustable to account for different size children. The system is applicable to a variety of chair shapes and sizes, depending on the school or child where the system is implemented.

Michigan State University

Team Members (left to right)

Drew Boudreau

Rochester Hills, Michigan

Kyle Fischer

Sterling Heights, Michigan

Nicole Kowalski

Reese, Michigan

Paige Cordts

Ann Arbor, Michigan

Chloe Ho

St. Johns, Michigan

Ingham ISD

Project Sponsors

Joanne Janicki

Mason, Michigan

ME Faculty Advisor

Dr. Siva Nadimpalli

Ingham ISD: Portable Ramp for Regular School Bus Use

Ingham Intermediate School District is in south mid- Michigan. Ingham ISD serves twelve public school districts, ten public school academies, and extends into seven different counties. Ingham ISD is a shared community resource for the school districts that it serves. Among the many districts that it supports is Mason Public Schools, which is the district that we worked with during this project. Our project sponsor is a physical therapist that works for Ingham ISD, and her role is to assist kids that have physical disabilities.

Our team was tasked with designing a bus ramp that could be easily installed on a regular international style bus. There is a student that attends Mason Public Schools that was unable to access regular school bus stairs due to a lack of mobility in her hips and knees. This made it impossible for her to ride the bus with her friends. Therefore, the goal of this project was to design something that would allow her to navigate the bus stairs without any issues. The design was created because of her need but is intended to be accessible for all students that have similar difficulties.

Michigan State University

Team Members (left to right)

Nathan Ansbro

Brighton, Michigan

Allison Keller

Clarkston, Michigan

Rahmi Khalil

Macomb, Michigan

Jerica Tallman

Grand Haven, Michigan

Matthew Stucky

Grass Lake, Michigan

Ingham ISD

Project Sponsors

Kristi Weber

Mason, Michigan

ME Faculty Advisor

Dr. Manoochehr Koochesfahani

Ingham ISD: Step Therapy Device for Motor Skills Development

Ingham Intermediate School District is a regional education service agency and has been in operation since 1962. Many of the 350 staff members work directly in local schools and in community settings. Ingham Intermediate School District serves as a shared community resource that creates networks of support and enhanced educational opportunities for all learners in the service area.

This project is a collaboration with an Ingham ISD physical therapist and an Okemos Public Schools Autism Spectrum Disorder teacher to address an accessibility issue for students with Autism Spectrum Disorders and provide them an opportunity to practice motor skills, specifically with regard to negotiating bus stairs.

This task can be challenging due to attentional, motoric (physical), and behavioral issues. Many repetitions of a motor skill are necessary to master the skill. While practicing the task in the environment in which it occurs is ideal, this is not always practical for a variety of reasons such as scheduling, staffing, and weather. As the students master these skills, they are enabled to more fully participate in school activities. The device is a portable structure with steps on both sides. One side mimics a school bus with regards to height, depth, width, and handrails. The other side was designed with shallower steps to increase confidence, as well as adjustable handrails to accommodate the range of targeted students. Additional design aspects are the contrasting color at the edge of the steps, non-slip treads, and visual/auditory cues that indicate correct foot placement. The cues are removable as the student’s confidence and ability increase.

Michigan State University

Team Members (left to right)

Harrison Schaub

Suttons Bay, Michigan

Liam Ranik

Northville, Michigan

Hunter Hansen

Lansing, Michigan

Julie Pham

Lansing, Michigan

Raj Lamport

South Lyon, Michigan

Ingham ISD

Project Sponsors

Christina Wolfe

Mason, Michigan

ME Faculty Advisor

Dr. Abraham Engeda

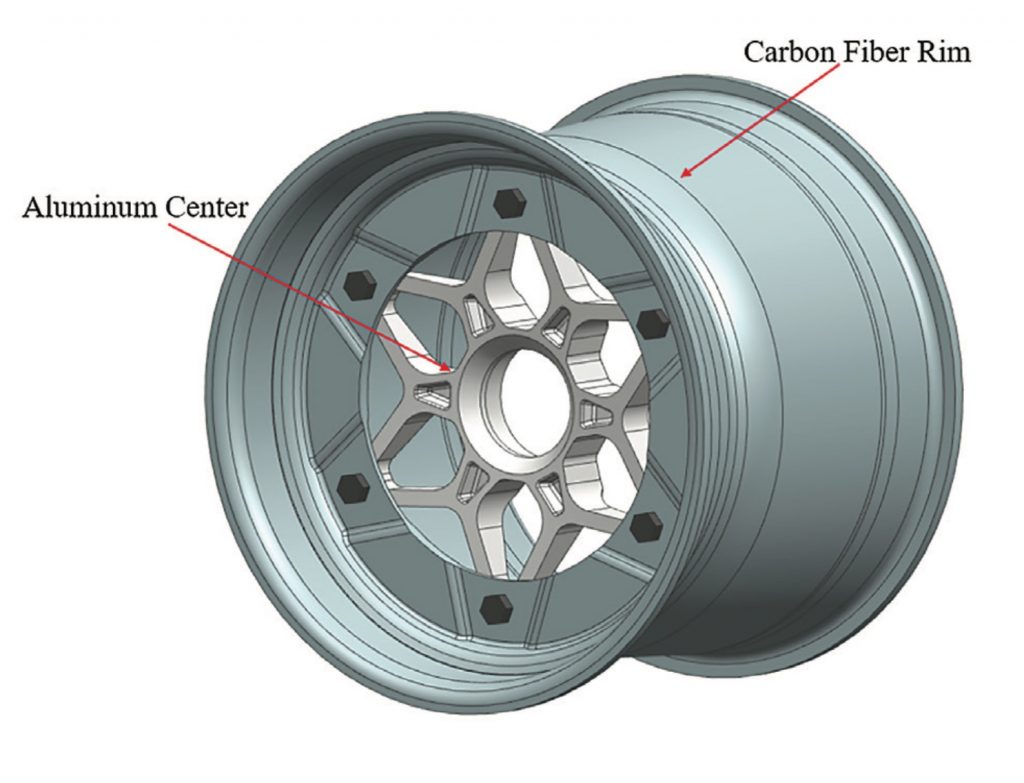

Lacks Enterprises/MSU Formula SAE Racing Team: Formula SAE Composite Wheels

Lacks Enterprises is a plastic molding and finishing organization comprised of three business units: Lacks Trim Systems, Plastic Plate, and Lacks Wheel Trim Systems. Lacks has been continuously developing their hybrid carbon fiber wheels since 2018, producing wheels that have the longevity, beauty, and strength of the aluminum wheel that it replaces. Formula SAE is a collegiate competition that challenges students to design, build, test, and race small, open wheel cars against universities from all around the world. Teams spend 8-12 months designing, building, and preparing their vehicles for competition. These cars are judged in a series of static and dynamic events, technical inspection, cost, presentation, engineering design and high-performance endurance. Michigan State competes in the main competition at Michigan International Speedway every year.

The team designed and manufactured a hybrid wheel, consisting of a carbon fiber reinforced plastic rim with an aluminum center to be used by Michigan State’s Formula SAE team to reduce the overall weight of the car and reduce lap times. The carbon fiber wheels lowered rotational inertia in the outboard assemblies and maintained better contact with the ground due to decreased weight. They also increased stiffness, which reduced compliance and increased the tire’s lateral capability under loading. The team created a replicable process to produce multiple sets of wheels using the same molds and developed testing procedures to analyze failure modes, both through simulation and on track testing.

Michigan State University

Team Members (left to right)

Andrew McNamara

Petoskey, Michigan

Abhyuday Rastogi

New Delhi, India

James McDonald

Grand Rapids, Michigan

Zach Harrison

Canton, Michigan

Sean Martella

Rockford, Michigan

Nelson Huynh

Grand Rapids, Michigan

Lacks Enterprises/MSU Formula SAE Team

Project Sponsors

Christopher McCloskey

Kentwood, Michigan

ME Faculty Advisor

Dr. Gary Cloud

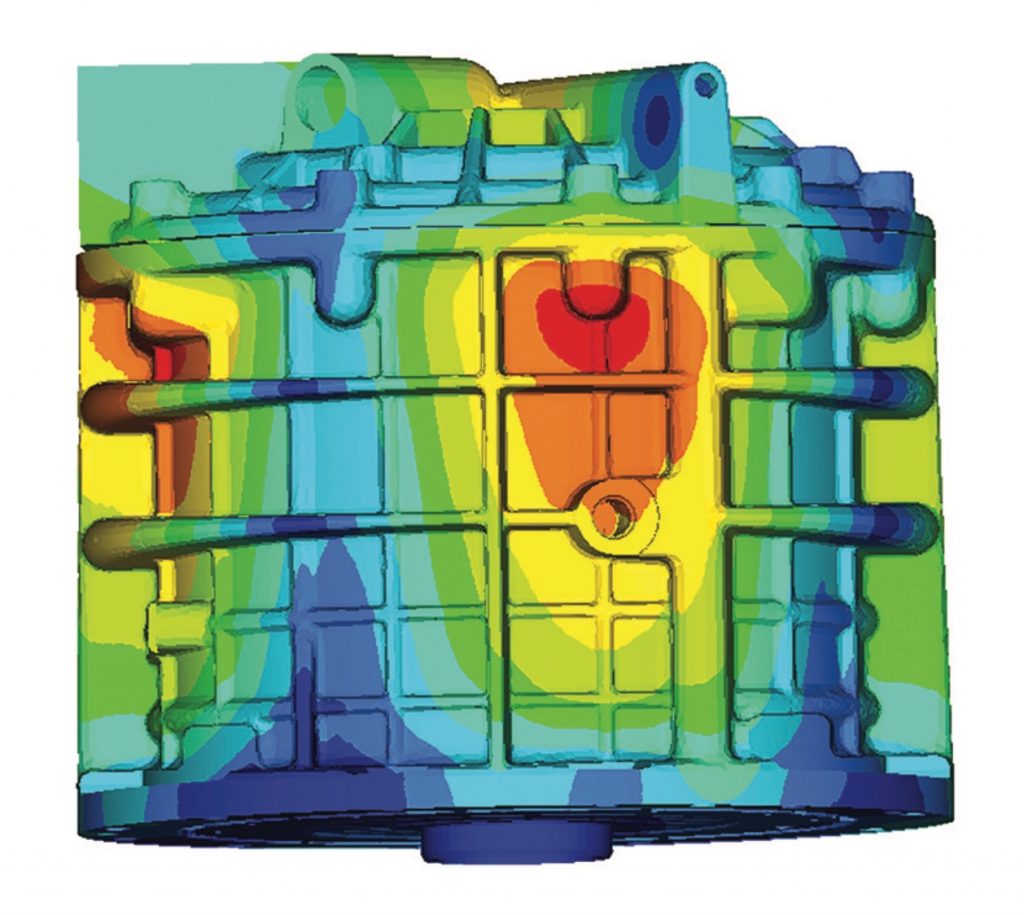

McLaren Engineering: Design Factors Affecting Radiated Noise of an e-Axle Housing

McLaren Engineering, located in Livonia, Michigan has additional technical centers located in North America, Europe, and China. McLaren Engineering has made a name for itself throughout the years with their expertise in engine and transmission/driveline design and engineering. With the recent demand for electrically powered vehicles the company has shifted some of its focus and resources to this expanding market.

McLaren Engineering focuses on the design, development, and testing of several components and systems in traditional internal combustion, hybrid, and electrically powered propulsion systems. Their testing capabilities include rapid prototyping, Noise, Vibration, and Harshness (NVH)/acoustic evaluation, performance/development durability, mechanical testing, metallurgical inspection, and cold fluid testing. This wide range of testing capabilities has allowed them to address some of the elevated NVH problems that have been found in the gearboxes and drivelines of hybrid and electric vehicles. McLaren Engineering’s focus is to find a cost-effective solution to these challenges that allows the consumer to enjoy the quietest ride possible.

Our team was tasked with developing an understanding of the factors influencing radiated noise from propulsion system structures. There were several variables that our team had to consider when attempting to improve the NVH values that the components of the e-axle housing were experiencing, including wall thickness, ribbing, and material. Axle housing units contain many complex parts, so our group had to test the effects of these variables on multiple components, a flat plate, and a cylinder. This research has provided McLaren Engineering with further insight on the impact of material, component geometry, and ribbing techniques that they can incorporate into their products and provide consumers with a smoother sounding vehicle.

Michigan State University

Team Members (left to right)

Ailohi Izirein

Ypsilanti, Michigan

Matthew Simental

Frankfort, Illinois

Akhilesh Swaminathan

Vadodara, India

Michael Vangel

Commerce, Michigan

Marcelo Zapiain Pruneda

Monterrey, Mexico

McLaren Engineering

Project Sponsors

Brian Wilson

Livonia, Michigan

ME Faculty Advisor

Dr. Himanshu Sahasrabudhe

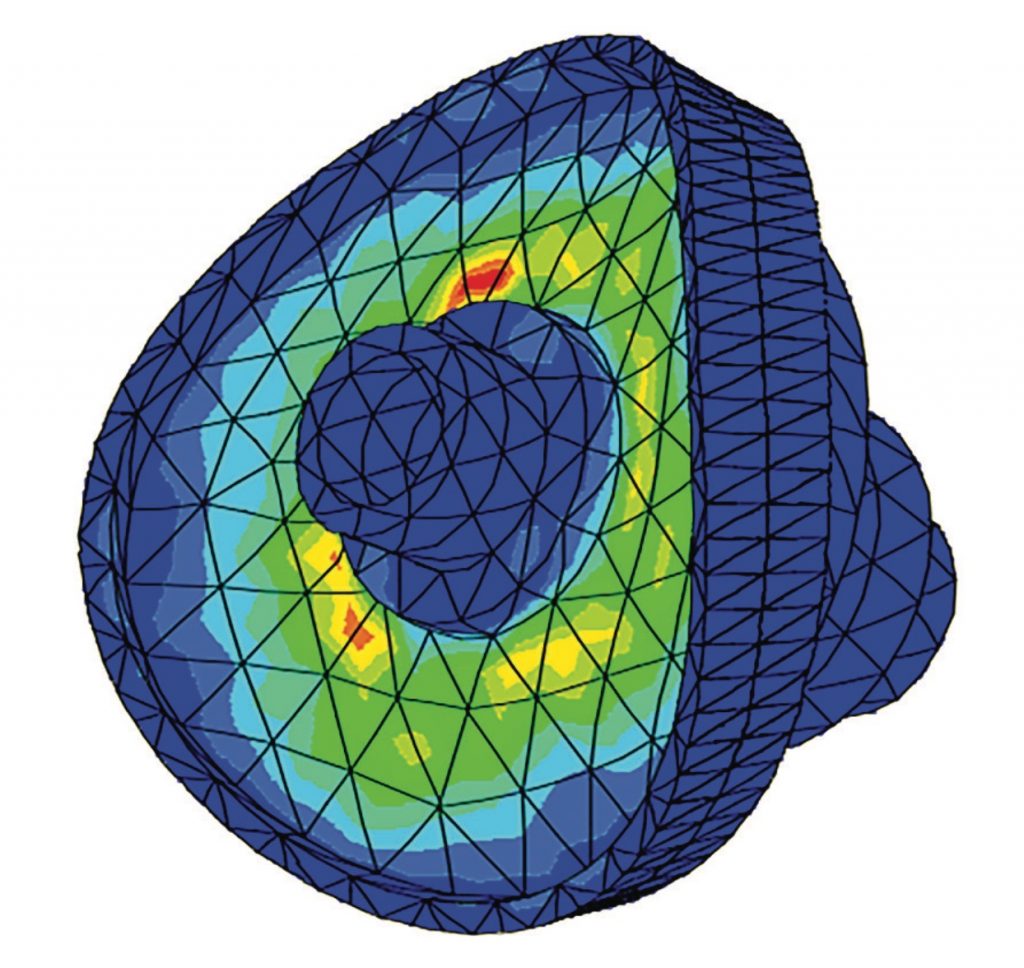

McLaren Engineering: Gear Design for Noise Reduction

McLaren Engineering is Linamar’s leading-edge technology and product development team for its mobility segment. The foundation for Linamar’s technical advancements is rooted in the expertise of McLaren Engineering. Purchased by Linamar in 2003, McLaren provides design, development, integration, manufacturing, and testing capabilities that provide its customers a world-class, full-service supplier partner that develops complete vehicle powertrain and driveline systems for both the global electrified and traditionally powered vehicles.

Our team has been tasked with developing an automated Computer Aided Engineering (CAE) analysis process for the EV propulsion system Noise, Vibration and Harshness (NVH) issues – or, more specifically, gear whine. This issue is significant because EVs lack the masking noise produced by classic Internal Combustion Engines (ICEs), resulting in more prominent tonal noise that annoys car passengers. Additionally, the electric motors that power EV e-axles operate at high speeds, causing high-frequency tonal noise in the passenger compartment. This noise may be mitigated by adjusting the dynamic compliance of the gear mesh, or “tuning” the gear, in order to reduce the gear meshing force, and thereby reduce the tonal noise. Dynamic compliance analyses can be run by CAD/ CAE applications, so the focus of our project is to develop a tool to automate the tuning and frequency response analysis of gears for design space exploration purposes.

McLaren Engineering is Linamar’s leading-edge technology and product development team for its mobility segment. The foundation for Linamar’s technical advancements is rooted in the expertise of McLaren Engineering. Purchased by Linamar in 2003, McLaren provides design, development, integration, manufacturing, and testing capabilities that provide its customers a world-class, full-service supplier partner that develops complete vehicle powertrain and driveline systems for both the global electrified and traditionally powered vehicles.

Our team has been tasked with developing an automated Computer Aided Engineering (CAE) analysis process for the EV propulsion system Noise, Vibration and Harshness (NVH) issues – or, more specifically, gear whine. This issue is significant because EVs lack the masking noise produced by classic Internal Combustion Engines (ICEs), resulting in more prominent tonal noise that annoys car passengers. Additionally, the electric motors that power EV e-axles operate at high speeds, causing high-frequency tonal noise in the passenger compartment. This noise may be mitigated by adjusting the dynamic compliance of the gear mesh, or “tuning” the gear, in order to reduce the gear meshing force, and thereby reduce the tonal noise. Dynamic compliance analyses can be run by CAD/ CAE applications, so the focus of our project is to develop a tool to automate the tuning and frequency response analysis of gears for design space exploration purposes.

Michigan State University

Team Members (left to right)

Claudia Chen

Canton, Michigan

Douglas Heine

Chapel Hill, North Carolina

Emanuelle Carduner

Bloomfield Hills, Michigan

Ha Ninh Dang

Hanoi, Vietnam

Zhihao Xu

Shanghai, China

Kanglin Ma

Okemos, Michigan

McLaren Engineering

Project Sponsors

Pat Murphy Livonia, Michigan

Brian K. Wilson Livonia, Michigan

ME Faculty Advisor

Dr. Himanshu Sahasrabudhe

Michigan AgrAbility: Self-Propelled Beehive Lifting Mechanism

Michigan AgrAbility offers no-cost solutions to aid people with injuries, illnesses, or disabilities in the agricultural industry through the partnerships between Michigan State University and Easterseals Michigan. Michigan AgrAbility, along with Heros to Hives, has set out to assist Michigan veterans to start and continue to keep bees. For this specific task, the beekeepers with back and leg injuries cannot always lift the hives for inspection. With the reducing bee population due to diseases, constant inspection is critical to maintaining healthy hives throughout the year. These hives can weigh anywhere between 90 to 300 pounds and with constant inspections needed, this task may be difficult or not possible for some beekeepers. Michigan AgrAbility wants to make sure these issues do not continue to impede beekeepers by providing the necessary tools and resources to aid them in their work.

Our team was tasked with designing a self-propelled beehive lifting mechanism that aids beekeepers by lifting and transporting the hives during inspections. A previous design team completed the base for the lifter. Thus, the goal of this semester was to construct the lifting mechanism and drive component. The lifter is designed to carry 300 pounds over rough and difficult terrain. The lifter is a two-frame system made from carbon steel. The smaller frame is connected to a track and carriage system in the large frame. Fork arms are connected to the smaller frame and made manually adjustable to account for different size boxes. There are folding flaps on the forks to grab and release the box handles. With the help of Michigan AgrAbility and their controls expert, all controls will be powered by a 24V battery system. Additionally, the lifter is operated by two easy-to-use joysticks. The team’s lifting mechanism will help ensure beekeepers with illnesses, injuries, and disabilities are able to continue their work with ease.

Michigan State University

Team Members (left to right)

Livia Noble

Macomb, Michigan

Abigail Bowman

Haslett, Michigan

Eric Parsons

Midland, Michigan

Ethan Mulder

Wixom, Michigan

Nick DeMeester

Grand Rapids, Michigan

Michigan AgrAbility

Project Sponsors

John Ferris Austin, Texas Ned Stoller Grand Rapids, Michigan

ME Faculty Advisor

Dr. Thomas Pence

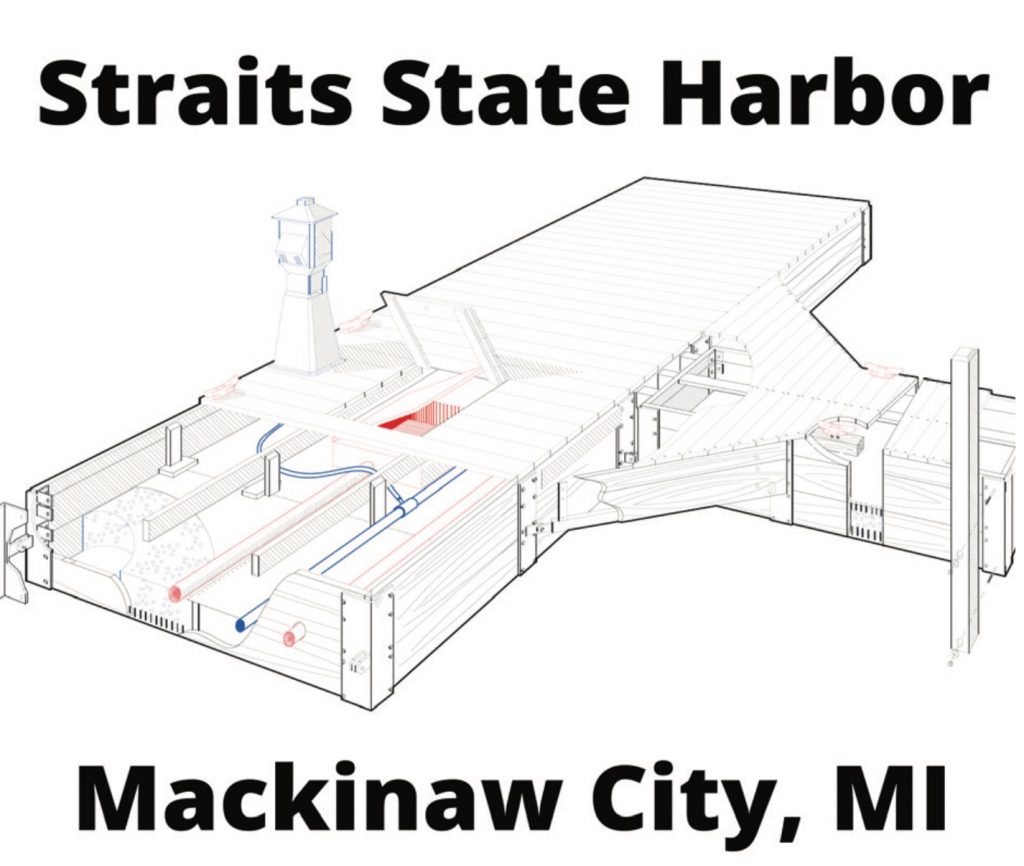

Michigan Department of Natural Resources: Efficiency of Ice Suppression Systems

The Michigan Department of Natural Resources (DNR) is the agency appointed by the state of Michigan which is charged with maintaining Michigan’s natural resources such as state parks, state forests, state harbors, and other recreational areas. The state of Michigan boasts unique and challenging seasons with varying temperatures year- round. During the winter months, Northern Michigan sees temperatures continuously below freezing. As Northern Michigan is a hub for industry and tourism at the state and national level, especially in the summer months, it is necessary to keep these resources accessible, and in good condition throughout the year. Access to harbors, which provide access to the Great Lakes, is essential in keeping this area available to tourists and natives of Michigan alike. Straits State Harbor in Mackinaw City serves as a prime example of a place that is vital to industry, tourism, and recreation year-round.

To ensure that the harbors are safe and ready for use during the difficult months of winter, systems have been implemented to reduce and eliminate the amount of ice that forms in the harbors. The two types of systems commonly used are ice eater systems and bubbler systems. The ice eater system incorporates a propeller that agitates the water below the surface and forces warmer water below the ice upwards to melt the ice on the surface and keep the area clear of ice. The bubbler system applies the same principle of moving warmer water upwards but through the use of air bubbles that are generated by a pump and pipe system below the surface. Currently, Straits State Harbor operates a bubbler system. In order to ensure operability at all times of the year, effects of motor wear on the current system’s performance, efficiency of system types compared to one another, and efficiency improvements due to zoning changes were explored to maximize energy efficiency, minimize costs, and improve ice suppression capabilities at Straits State Harbor.

Michigan State University

Team Members (left to right)

Michael Batina

Wheaton, Illinois

Bobby DiPanni

Rochester, Michigan

Jack Hennessey

Rochester, Michigan

Robert Pedder

Troy, Michigan

Steven Stine

Fraser, Michigan

Battleship New Jersey Museum & Memorial

Project Sponsors

Dave Stempky

Cheboygan, Michigan

Gerald Vieau

Cheboygan, Michigan

ME Faculty Advisor

Dr. Indrek Wichman

MSU Adaptive Sports & Recreation Club: Inclusive Sports Wheelchair

The MSU Adaptive Sports & Recreation Club’s purpose is to promote the benefits of physical activities to individuals with physical disabilities. The club establishes a space where athletes with physical disabilities and able-bodied volunteers can come together to create an integrated community of peers that serves to eradicate negative stereotypes about disability by highlighting the abilities of individuals with physical disabilities. There are multiple sports that are played through the MSU Adaptive Sports & Recreation Club, which include wheelchair hockey, wheelchair tennis, wheelchair basketball, wheelchair rugby, rowing, boccia ball, discus throw, handcycling, and many more. These sports are extremely important for the individuals in the inclusive sports. It gives the individuals the ability to become stronger, complete goals, and interact with peers.

Over the past few years, an existing wheelchair has been modified to fit the needs of a club member, David. Traditional designs for these wheelchairs focus on individuals who have limited mobility in the lower half of their body, whereas this wheelchair was designed for limited mobility in the left half of the body. To modify and improve the existing design of David’s adaptive sports wheelchair, a previous team implemented a steering system allowing the chair to brake on one side or the other. This semester the function of the chair was improved by implementing an efficient way to brake both wheels, allowing the chair to come to a complete stop, while keeping David comfortable and not be physically demanding. This was achieved using David as a resource to know what movements are comfortable for him. The system that was developed was efficient, and David was able to use the wheelchair with ease.

Michigan State University

Team Members (left to right)

Ryan Knutson

Lake Orion, Michigan

Allison Fox

Lake Orion, Michigan

Claire McMillen

West Bloomfield, Michigan

Jacob Wescott

DeWitt, Michigan

Zack Stroud

Northville, Michigan

Trent Treppa

Algonac, Michigan

MSU Adaptive Sports & Recreation Club

Project Sponsors

Piotr Pasik

East Lansing, Michigan

ME Faculty Advisor

Dr. Rebecca Anthony

MSU Adaptive Sports & Recreation Club: Increasing Hockey Sled Mobility

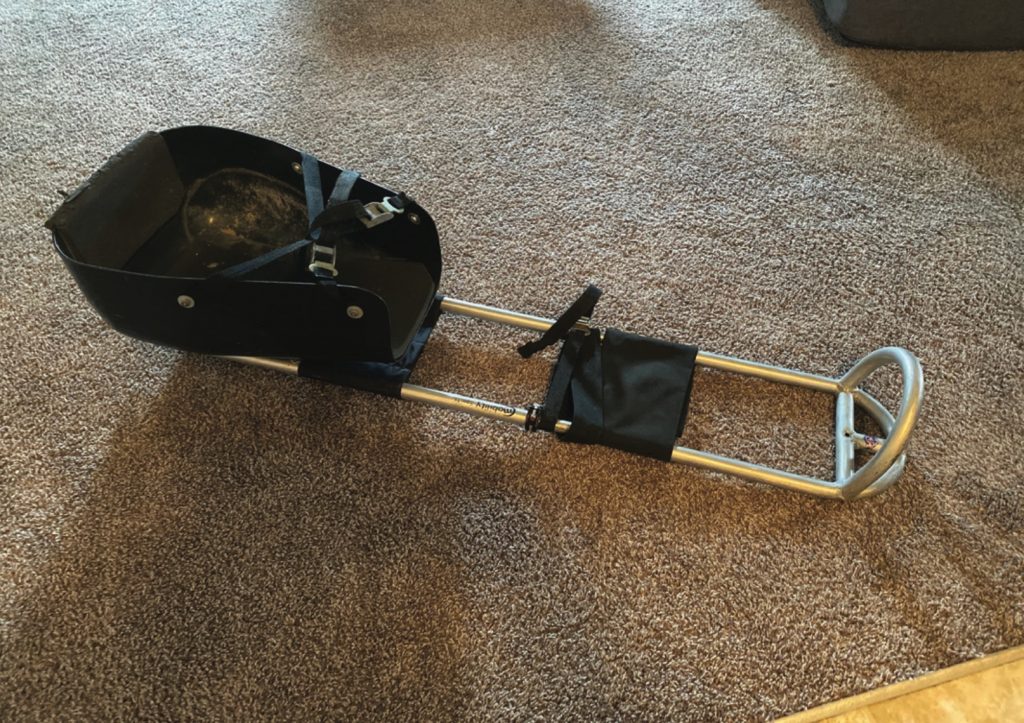

The MSU Adaptive Sports & Recreation Club is an inclusive club that promotes health, wellness, and teamwork through sports for individuals with physical disabilities. The club wanted to implement a new sport into their program called Sled Roller Hockey. This game would be played on a hockey rink at Demonstration Hall. However, the hockey rink is not made of ice, it is made of a rubber material. Roller Hockey Sleds will be used on this surface. A previous group developed a prototype of the Roller Hockey Sled, and our task is to improve its functionality to make it more inclusive.

The club provided our team with the previous design of the sled called the Phase 1 Design. Our focus is on improving the speed, acceleration, and turning ability of that sled. We plan on doing this by redesigning the bottom of the sled. Specifically, we will redesign the wheel layout, material of the wheel, and how the wheels spin. We will also add camber wheels to improve turning capabilities and study the surface of Demonstration Hall to reduce the amount of friction caused by the wheels. The current design of the sled requires a lot of upper body strength to move it, so someone with physical disabilities might not be able to use the sled at all. Our goal is to make the sled more inclusive and easier to use. Designing a sled with higher performance will make the game more competitive and fun!

Michigan State University

Team Members (left to right)

Alex Toth

Grosse Ile, Michigan

Cam Depauli

Walled Lake, Michigan

Cody Hayse

Williamston, Michigan

Griffin Yakey

Fraser, Michigan

John Paul Dela Cruz

Canton, Michigan

MSU Adaptive Sports & Recreation Club

Project Sponsors

Piotr Pasik

East Lansing, Michigan

ME Faculty Advisor

Dr. Mohsen Zayernour

MSU Adaptive Sports & Recreation Club: Sled Hockey Transfer Platform: Phase V

The MSU Adaptive Sports and Recreation Club is an organization that includes athletes and individuals with physical disabilities as well as volunteers and members of a greater community. Within the adaptive sports community promoting a physical and socially accessible space is a continually evolving task. The club has established an integrated community through a variety of sports including sled hockey. While constantly promoting physical health, social behavior, and psychological wellness through adaptive sports, the community strives to provide a self-determination approach focusing on athlete autonomy, competence, and relatability. By doing this the club has provided members with increased independence and enhanced quality of life, leading to success both in sports and in other domains.

Our team focused on the locking mechanism of the sled and the handles of the transfer platform to help improve the overall independence and durability of the device. These changes included modifications of the handrails and the locking mechanism from the previous design. These changes provided better functionality and safety, accommodating users with varying levels of mobility.

Michigan State University

Team Members (left to right)

Mark Pastoria

Clinton Township, Michigan

Tucker Hendrie

Rockford, Michigan

Justin Helmer

Ionia, Michigan

Garrett Gould

Muir, Michigan

Katlyn Knudsen

Ludington, Michigan

Jessica Thomas

Alto, Michigan

MSU Adaptive Sports & Recreation Club

Project Sponsors

Piotr Pasik

East Lansing, Michigan

ME Faculty Advisor

Dr. Indrek Wichman

MSU Department of Mechanical Engineering: Piston Friction Reduction to Improve Engine Efficiency

The Michigan State University Department of Mechanical Engineering is the second largest department in the College of Engineering, making up over 26% of students in the college. Professors within the Department of Mechanical Engineering conduct leading edge research with funding and sponsorships from numerous US organizations and industries, which give undergraduate students the opportunity to volunteer or work.

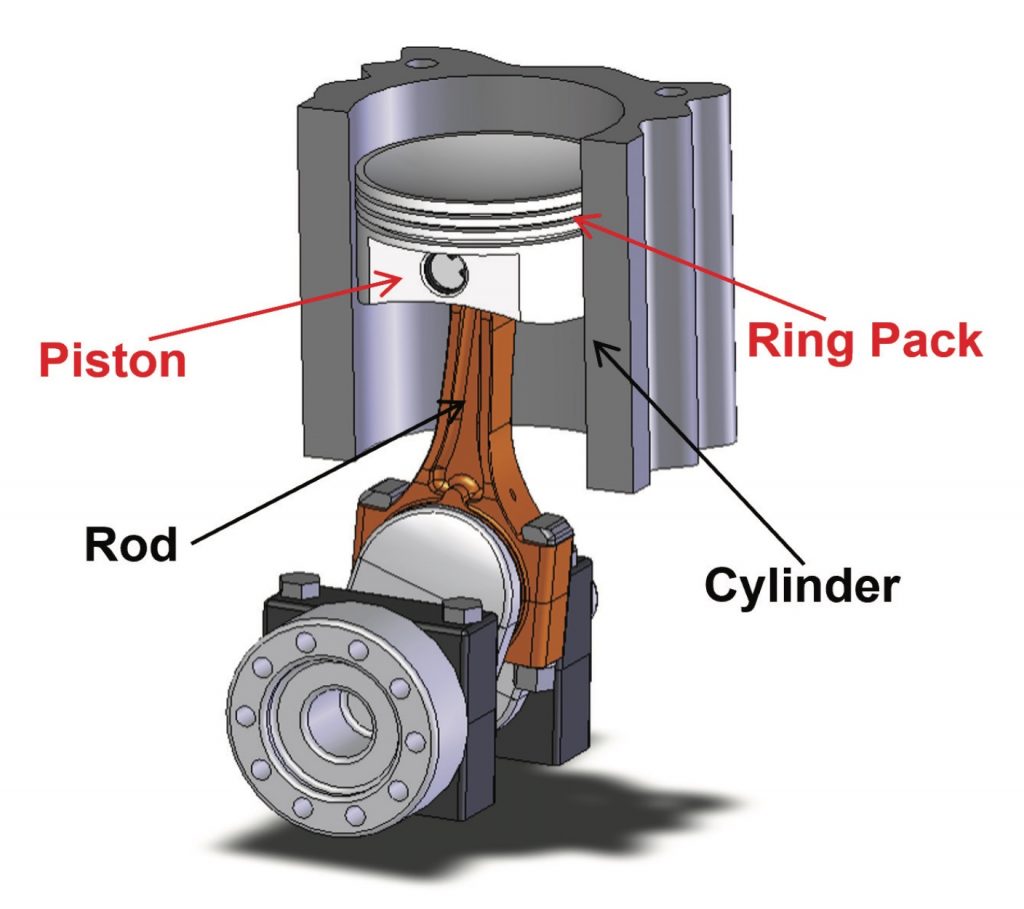

Nearly two hundred million piston engines are put into service each year. Engineers globally are working to design and optimize pistons to reduce contact friction between the piston and liner, while concurrently limiting wear due to the lateral motion of the piston within the cylinder. Using a software tool called CASE, our team conducted numerous optimizations on a typical piston skirt profile below the ring pack region to minimize the frictional forces experienced by the piston and to determine the magnitude of these forces. Research has revealed that minor changes to the piston geometry could have significant effects on piston-to-liner friction, which accounts for nearly 20% of the losses that occur within an internal combustion engine. Minimizing these frictional forces was critical to improving the efficiency of these internal combustion engines.

Our team was tasked with developing an initial design of a testing fixture that will be used to validate the findings from the software optimizations. In the future, our initial testing fixture design will be improved and manufactured to aid the Michigan State University Department of Mechanical Engineering and Energy and Automotive Research Lab in the experimental validation of computational models.

Michigan State University

Team Members (left to right)

Jack Voigt Birmingham, Michigan

Justine Stewart Chesterfield, Michigan

Landon Luyckx Bloomfield Hills, Michigan

Mason Perillo New Lenox, Illinois

Hailey Swamy Grosse Ile, Michigan

Kylie Decker Mason, Ohio

MSU Department of Mechanical Engineering

Project Sponsors

Daniel Nicklowitz

East Lansing, Michigan

Harold Schock

East Lansing, Michigan

ME Faculty Advisor

Dr. Harold Schock

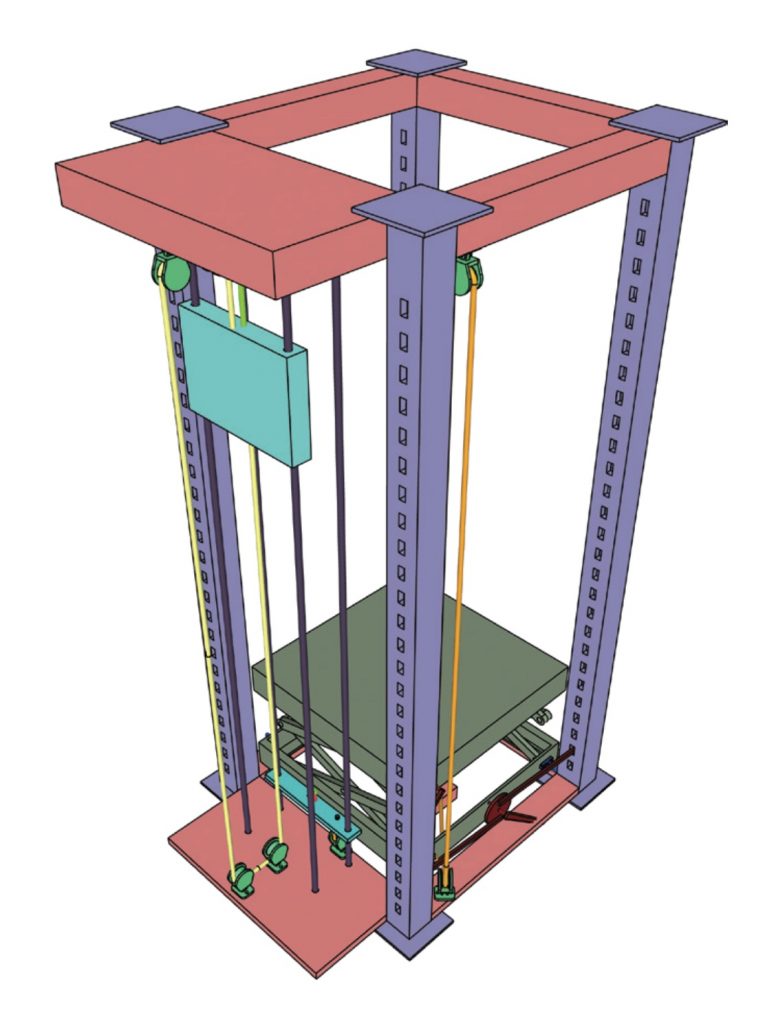

MSU Department of Theatre: Counterweight Elevator

Beginning in 1968, Michigan State University’s Department of Theatre has been pushing the boundaries of musicals and plays for over fifty years. Known for its groundbreaking theatrical stage designs and extravagant performances, the Department of Theatre uses the performing arts to better express current events. It allows students to express themselves more fully and choose their own path, which helps them grow into more gifted individuals. This department is ever changing as theatrical styles and forms change to reflect current societal issues. Although the Department of Theatre is currently only putting on smaller performances due to Covid-19, it usually has many different large- scale musicals or plays being performed throughout the year. This means that stage design and implementation must be quick and effective, so any premade intricate parts that are adjustable are invaluable concerning time management.

The objective of this project was to build a counterweight elevator that would be built into a stage platform. The elevator would have a person stand on it as it lowers them down slowly, creating a sinking feeling. The elevator has a complex pulley system design which meets the desired factor of safety of 8. The system is operated by two people. The platform is portable and can adjust to the stage height, which can vary from 6 to 10 feet. The system has a built-in safety system that will stop the elevator from free falling if the rope breaks.

Michigan State University

Team Members (left to right)

Anthony Kasiyan

East Lansing, Michigan

Elias Mackoul

East Lansing, Michigan

Atharva Wadhokar

Pune, India

Smitkumar Patel

Canton, Michigan

Nathan Vigneau

Lambertville, Michigan

MSU Department of Theatre

Project Sponsors

Mark Willoughby

East Lansing, Michigan

ME Faculty Advisor

Dr. Sara Roccabianca

MSU Recycling Center: Improved Cart Tipper Design

The MSU Recycling Center manages MSU waste through an integrated system of reuse, recycle, and educate. Each year it processes between 20 to 25 million pounds of material that is discarded on MSU’s campus. The discarded material comes in the form of recyclables, pre-consumer food waste, and surplus goods donated by departments and the community. Our project focused on the food waste system employed by the MSU Recycling Center, which prevents an average 10 to 20 carts per day of food waste produced from on-campus dining halls from going to the landfill. There are two different carts that separate compostable food waste from other food waste. The compostable food is fed to onsite worms that convert the food into compost. Food that isn’t sent to the onsite worms is either sent to a digester for energy or is sent off site for composting. The other food waste is sent to be processed and used for energy on the MSU Farms. Both carts utilize a cart tipper that was the focus for our project.

The original cart tipper design had some structural flaws that made using it cumbersome and slowed down the efficiency of cleaning the carts. The cart tipper needed to be stationary when in use, but also portable for cleaning. Our task for this project was to improve the design of the cart tipper to make it faster and easier to use.

Michigan State University

Team Members (left to right)

Youngbin Song

Seoul, Korea

Veronica Giordano

Lake Bluff, Illinois

Valerie Aten

Lake City, Michigan

Jiachen Qu

Beijing, China

Zhemeng Fan

Shenzhen, China

MSU Recycling Center

Project Sponsors

Sean Barton

East Lansing, Michigan

ME Faculty Advisor

Dr. André Bénard

MSU Recycling Center: Recycling, Debagging and Film Removal

The MSU Recycling Center, located in East Lansing, Michigan, handles the University’s recycling needs. Each year, the center processes over 25 million pounds of discarded material from the University’s various academic buildings and residence halls. Currently, recycled materials arrive at the center inside of plastic film trash bags. The bags are then cut open by hand before being loaded onto a conveyor belt for sorting and eventual compaction. These bags, while great for keeping recyclables contained during transport, require workers to open them by hand once they reach the recycling center. This creates a less than ideal situation in which workers put themselves at risk while bottlenecking the recycling process. Recently, the recycling center installed robotic sorting technology capable of detecting missed recyclables while allowing for non-recyclable items to be discarded in a receptacle below. While this is great for the end of line processing, it does not eliminate the slow and potentially dangerous process of opening the film bags.

There are various methods used in the industry to help with this problem, but many require extensive funding or policy changes. Our team was tasked with researching these existing methods and coming up with our own solution that meets the university’s needs. We evaluated three possible solutions: a bladed conveyor belt- mounted device to cut through bags, a floor-mounted device to lift bags and streamline the cutting process, and a device fixed to the pile bunker to facilitate opening multiple bags simultaneously. The chosen solution will save money and help the university achieve its sustainability goals, making MSU a deeper shade of Spartan Green.

Michigan State University

Team Members (left to right)

Tanner Nurnberger

South Lyon, Michigan

Chris Sadler

South Lyon, Michigan

Braden Heiler

South Lyon, Michigan

Mitchell Rucyznski

Richmond, Michigan

Coleson White

South Lyon, Michigan

Jason Scott

Laramie, Wyoming

MSU Recycling Center

Project Sponsors

Sean Barton

East Lansing, Michigan

ME Faculty Advisor

Dr. Farhad Jaberi

MSU Solar Car Team: Solar Car Body and Chassis Design Prototype

Michigan State’s Solar racing team is a student run group focused on competitively designing and racing solar powered vehicles. The team competes in two solar “rayces” —The Formula Sun Grand Prix (FSGP) and the American Solar Challenge (ASC). FSGP is a track event that is held on grand prix or road style closed courses. ASC is a cross-country time/distance rally event where teams compete over a 2,000 mile course between multiple cities across the country. With 10 years of racing experience, the solar car team remains competitive by making continuous improvements to their vehicles. They have produced five complete vehicles – four Single Occupant (SOV) and one Multi Occupant (MOV). In the design of their upcoming vehicle, the team hopes to upgrade crucial aspects of the car’s aeroshell and chassis. These two aspects play a large role in the weight and aerodynamics of the vehicle, which are essential for producing a competitive vehicle. The team plans to begin manufacturing this vehicle by the end of summer 2022 and compete in FSGP and ASC 2024.

Using the information provided to our team by Michigan State’s solar racing team, we were able to assess the chassis and aeroshell design of the solar team’s previous SOVs. Additionally, we researched the designs of competitive vehicles, pulling the most from those that performed well in competition worldwide. The chassis and aeroshell created were modeled in Siemens NX. The chassis then went through extensive force analysis in the ANSYS Structure. The aerodynamics of the aeroshell were evaluated with the program Fluent. The design went through many iterations. Ultimately, we ended with a successful design that utilizes a safe frame design and an aeroshell that is aerodynamic to make the car as efficient as possible. A 3D printed scale model displays the final design that was chosen.

Michigan State University

Team Members (left to right)

Alyssa LaFeir

Sterling Heights, Michigan

Ryan Zerona

Canton, Michigan

Julia O’Mara (Sponsor)

Okemos, Michigan

Will Erskine

Ionia, Michigan

Ian Burress

Poquoson, Virginia

Zack Friess

Canton, Michigan

MSU Solar Car Team

Project Sponsors

Julia O’Mara

Okemos, Michigan

Joachim Hochwarth

Grand Rapids, Michigan

ME Faculty Advisor

Dr. Joerg Petrasch