MSU College of Music: Feel the Music

Fraunhofer USA: The Design and Fabrication of an Inkjet Printer for Selective Diamond Growth

Wyatt’s Creative Works, LLC.: Isn’t it LIFEly?

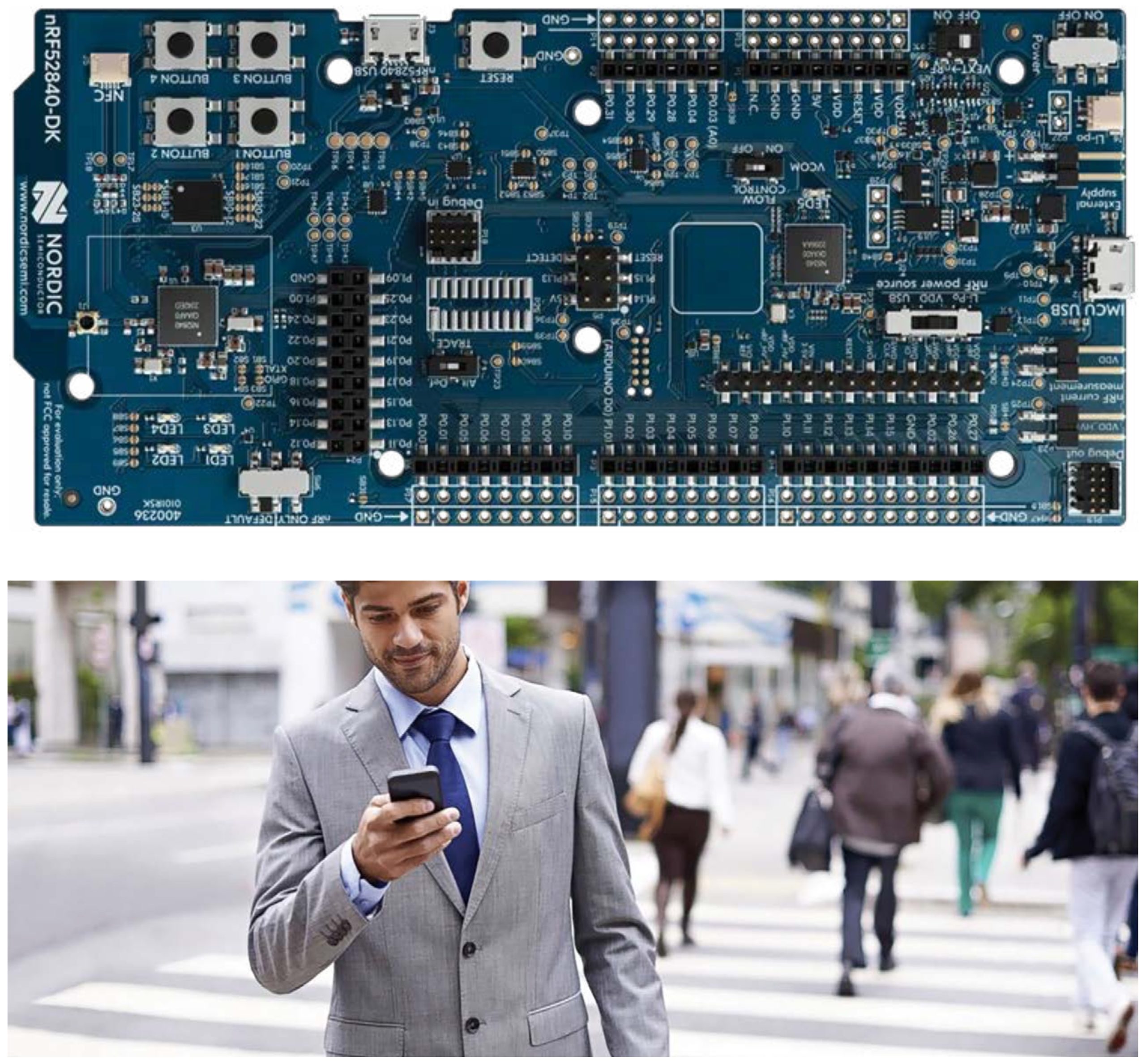

Valtech Mobility – Detroit, Safety Team: Pedestrian Crossing Awareness Service.

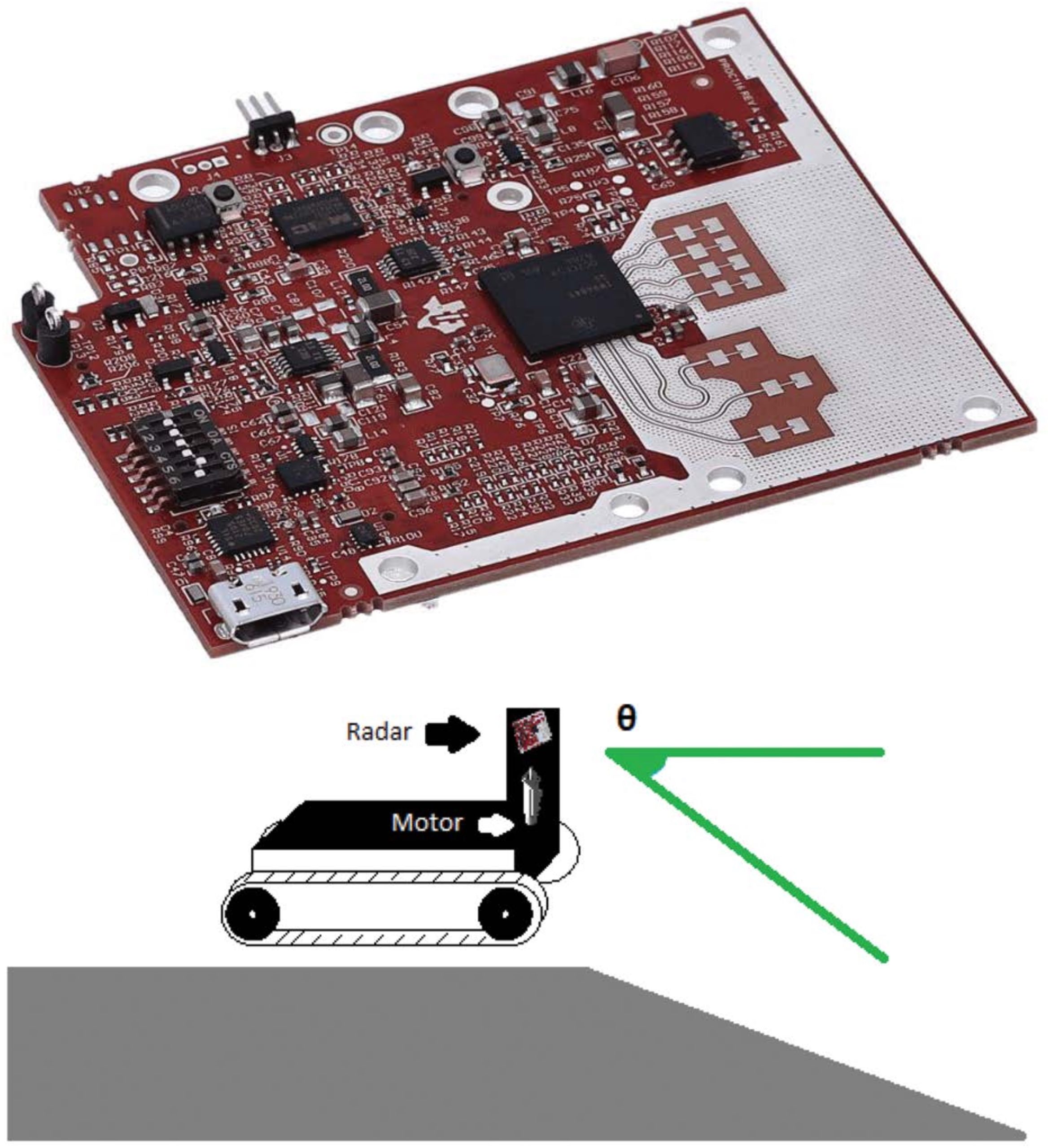

Texas Instruments: System for Slope Measurement with Radar

MSU Nondestructive Evaluation (NDE) Laboratory: Aerial Drone for Next Generation NDE

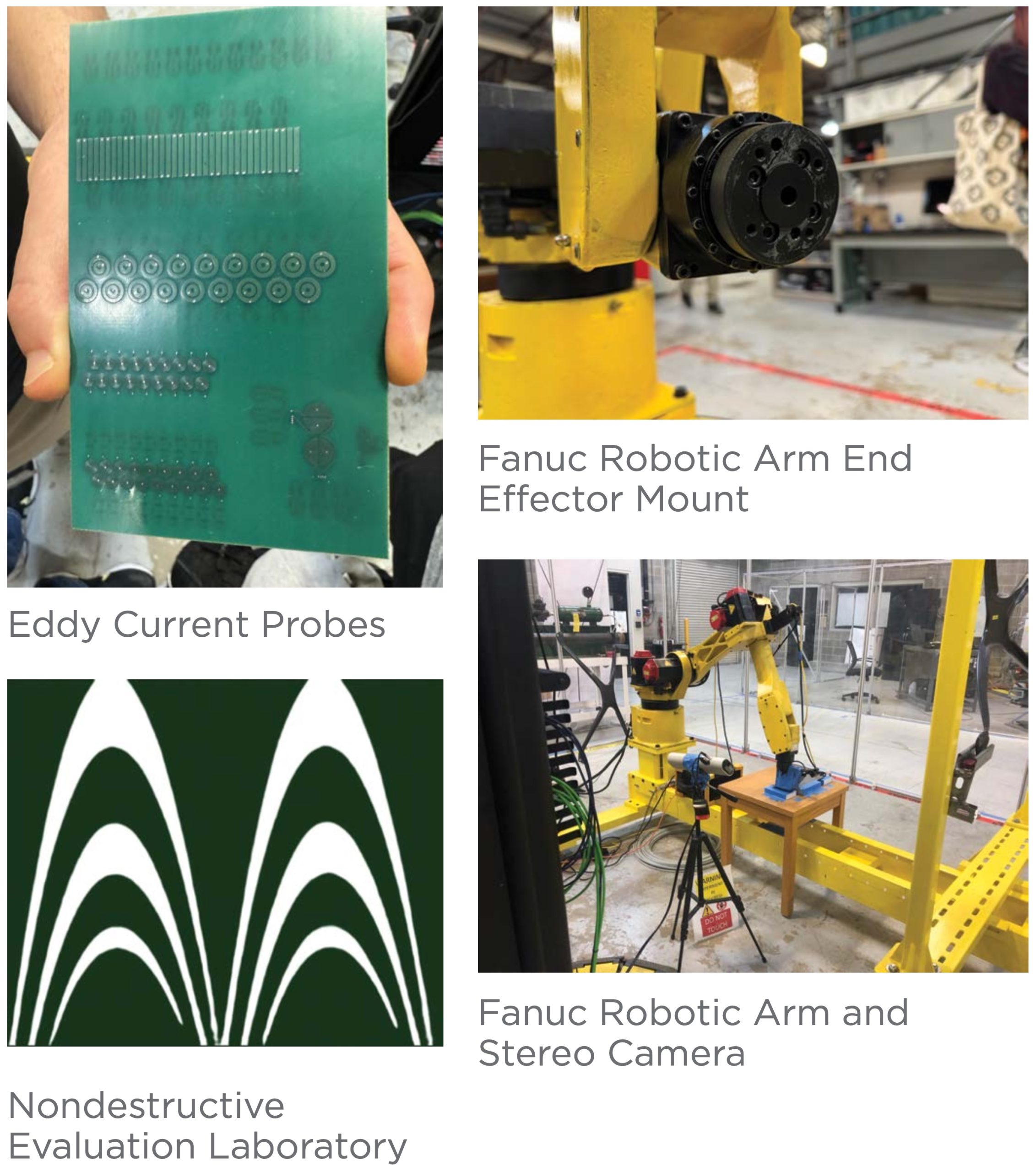

MSU Nondestructive Evaluation (NDE) Laboratory: Robotic Arm Object Reconstruction for NDE

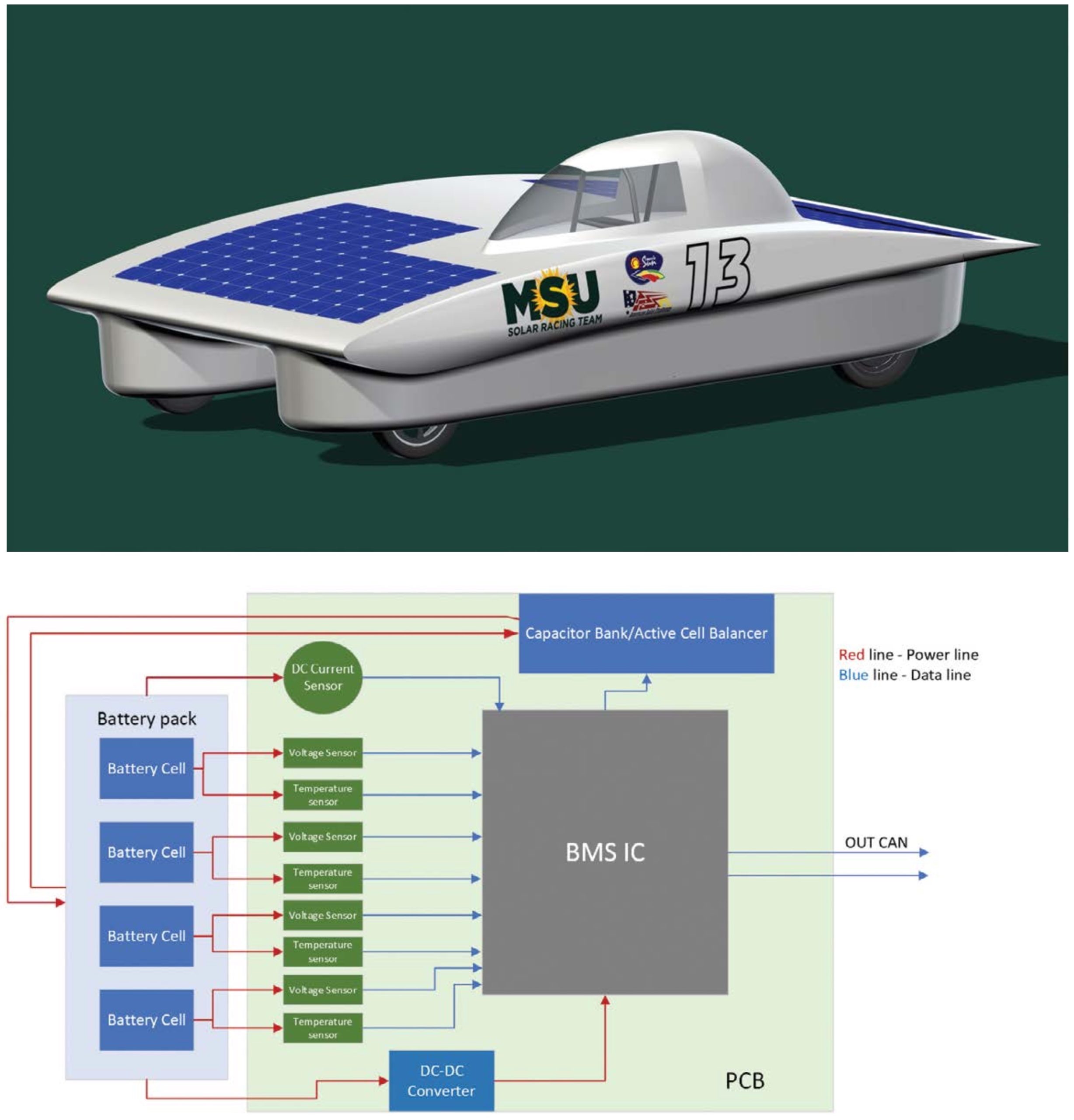

MSU Solar Racing Team: MSU Solar Car Battery Management System

MSU Solar Racing Team: Solar Car Steering Wheel Serial Communication

MSU D-CYPHER Lab: Design of Hardware-in-the-Loop Fire Simulator

MSU Department of Electrical and Computer Engineering: 24W DC-DC Converter

MSU College of Music: Feel the Music

When thinking of music in a general sense, most people think of bars with notes arranged on them to produce a melody. Though to a visually impaired individual, how would you go about describing what can be viewed? Braille notation provides a text description of what can be seen but what if there was a step further? What if there was a way to visualize music through touch?

The goal of this project is to create a 3D tactile approach to written music that overcomes limitations in Braille notation. The board is designed so that a visually impaired individual can interact with music as it was written by a composer. The board contains 3D notes that can be placed on the recessed staff lines to allow the individual to set up several measures at once. These measures play simultaneous staffs of notes with the proper duration and pitch.

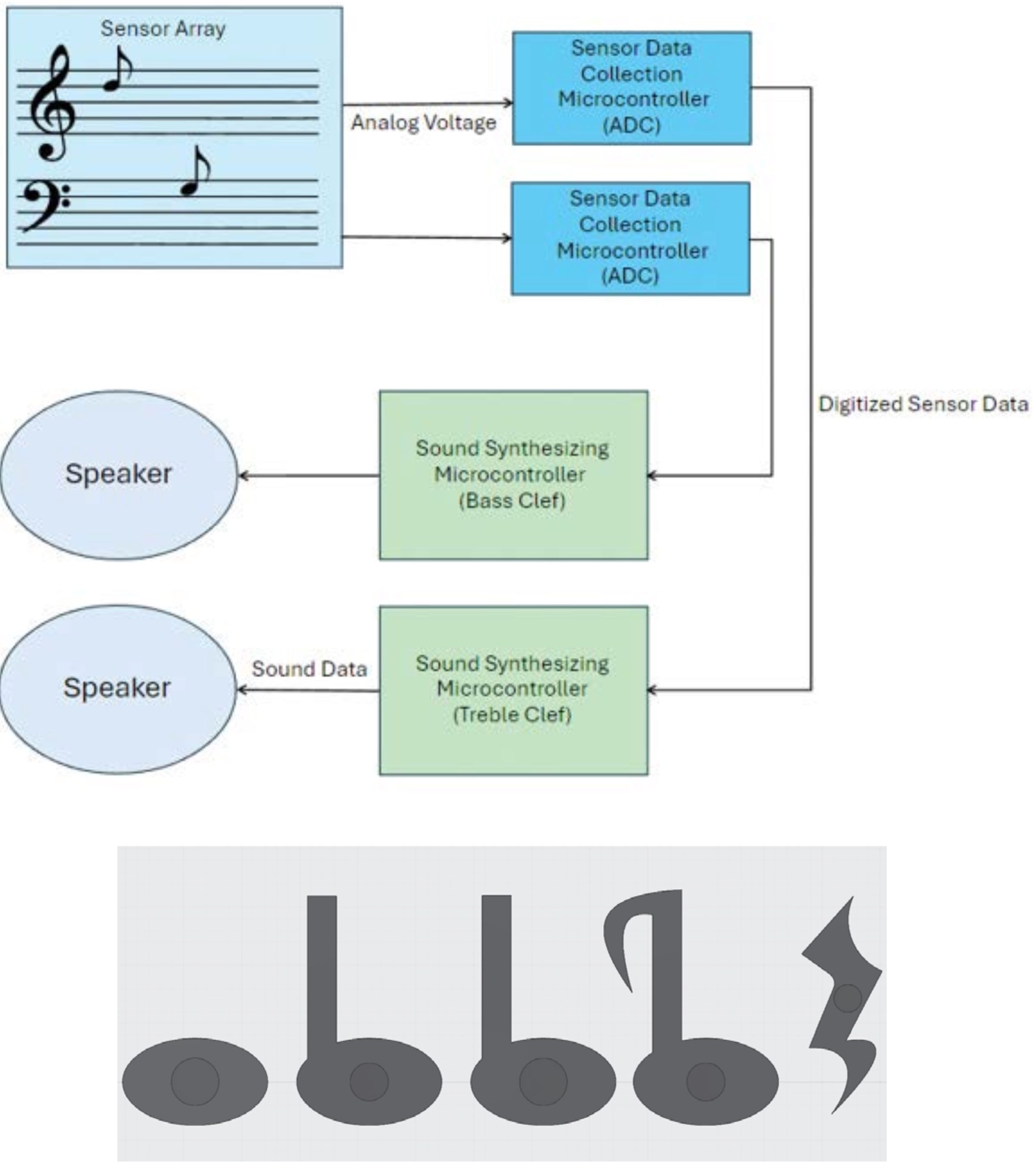

The top of the board has embedded metal plates that will react to the magnets embedded in the notes. These 3D notes can then be arranged on the top and bottom staffs on the board. Notes available to be placed on the board include eighth, quarter, half, and whole notes as well as a quarter rest (see the bottom right image).

To detect the note placement and duration, Hall effect sensors are placed just under the surface of the board near the metal plates. These Hall effect sensors change their output voltage if the magnet from a note or rest interacts with the sensor. From here, the voltages are passed through a signal processing system (see the top right image) that will ultimately end with the melody output through two separate speakers.

Michigan State University

Team Members (left to right)

Jason Ahn

Troy, Michigan

Spenser Lafferty

Commerce Township, Michigan

Maria Scannell

Plymouth, Michigan

Jason Shell

Grand Ledge, Michigan

Andrew Morgan

Grand Rapids, Michigan

MSU College of Music

Project Sponsors

Deborah Moriarty

East Lansing, Michigan

Project Facilitator

Dr. Daniel Morris

Fraunhofer USA: The Design and Fabrication of an Inkjet Printer for Selective Diamond Growth

Fraunhofer USA is a 501(c)(3) not-for-profit research and development organization that bridges the gap of academic research with industrial scaleup. In collaboration with Michigan State University is the Center Midwest Diamonds and Coatings Division, focused on diamond technologies, thin films, chemical measurements, water treatment and additive manufacturing.

One of Fraunhofer’s focuses is increasing the efficiency of diamond chip manufacturing. Currently, it consists of growing an entire silicon wafer with a diamond thin film and processing it. During the diamond patterning, the diamond needs to be removed, presenting a waste of resources, and requiring costly manufacturing equipment. Another issue is that when the diamond grows, there is internal strain causing bowing of the wafer and making it difficult to process. To overcome this, we are striving to develop a selective seeding system through using an inkjet printing device to print a diamond seeding solution directly onto the silicon wafer only where it is needed. This will take an entire step out of the original diamond development approach, which will save Fraunhofer time in the development process.

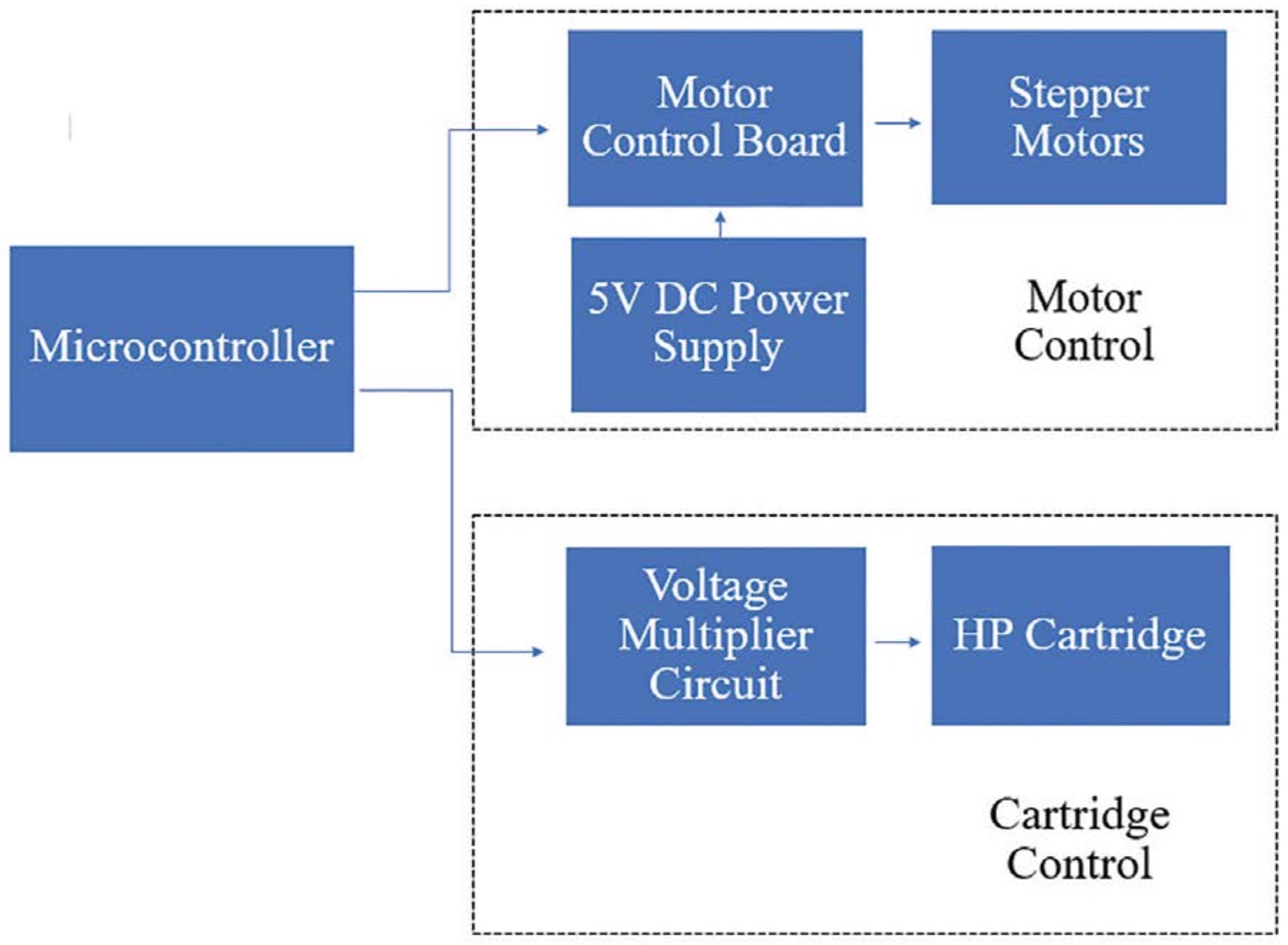

The printer can move in both the x- and y-axis directions to create the patterns and designs specified by the user. The z-direction is also implemented to enable wafers with varying thicknesses. Additionally, the user is able to interact with the printer to change the height of the nozzle. This will ensure the nozzle does not contact the wafer. If the nozzle does touch the wafer, it could create defect sites in the development process, disrupting the clean fabrication. The goal of this project is to have full control of all three axes, with an accuracy down to 30 micrometers to enhance the chip’s functionality and ensure it develops properly.

Michigan State University

Team Members (left to right)

Scott Risdon

St. Clair Shores, Michigan

Andrei Bodea

Ann Arbor, Michigan

Herminee Orzech

South Lyon, Michigan

Morgan Gates

Saginaw, Michigan

Joey Lopez

Clarkston, Michigan

Ruiqi Lu

Shanghai, China

Fraunhofer USA

Project Sponsors

James Siegenthaler

East Lansing, Michigan

Project Facilitator

Dr. Robert McGough

Wyatt’s Creative Works, LLC. Isn’t it LIFEly?

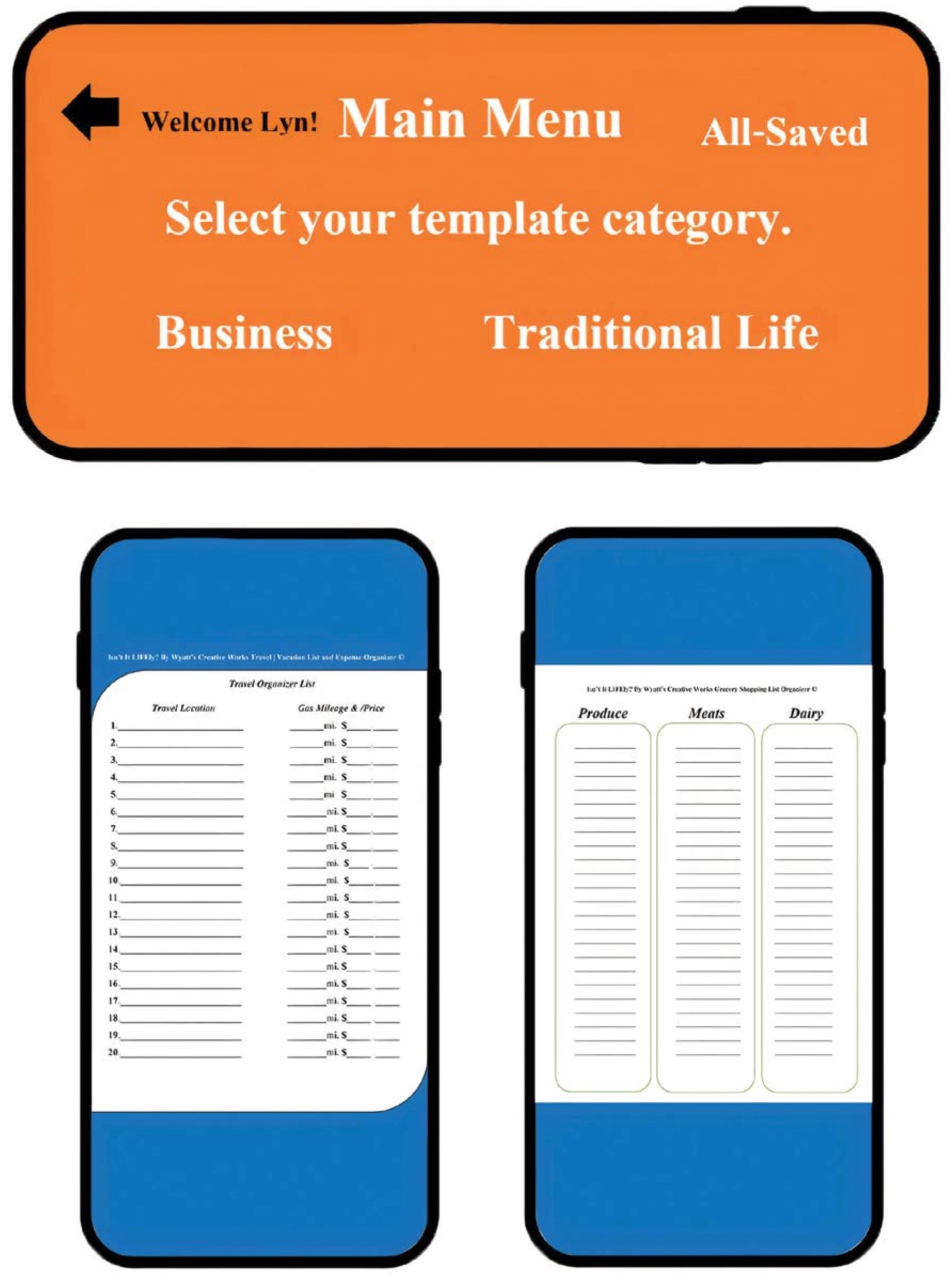

Wyatt’s Creative Works, a startup based in Grand Blanc, Michigan, is thrilled to reveal its latest venture into the digital realm with the development of a mobile application designed to improve personal and business organization. Leveraging the business’s expertise in content creation, ranging from publishing books to crafting innovative applications, we are tasked with creating a mobile application that seamlessly integrates into the daily lives of users, enhancing their ability to manage day-to-day tasks with ease and efficiency.

Our application ensures that all users’ organizational needs are covered by providing a variety of templates for notetaking and information tracking tailored to users’ diverse needs, such as managing bills and expenses to organizing grocery lists, setting agendas, and planning travel. Additionally, our application features a user-friendly toolbar equipped with drawing tools, allowing for the addition of personalized notes to any template. This customization aspect ensures that each user’s experience is unique, making their organizational tools truly their own.

To develop a mobile app for iOS and Android within our timeframe, we chose the open-source cross-development platform Flutter. Flutter utilizes the programming language Dart, which allows us to deploy mirror apps to both iOS and Android devices without needing to write in their native languages.

Data storage and authentication are handled via the backend-as-a- service product Google Firebase. Firebase integrates seamlessly with Flutter allowing for a streamlined development process and rapid prototyping, with minimal cost to the client.

Michigan State University

Team Members (left to right)

Mike Senecal

Howell, Michigan

Tim Kramer

Grand Rapids, Michigan

Bryan Malak

Walled Lake, Michigan

Adishvar Jeyaranjan

Novi, Michigan

Jayden DeVaull

Southfeild, Michigan

Wyatt’s Creative Works

Project Sponsor

Marquonda Wyatt

Grand Blanc, Michigan

Project Facilitator

Dr. Panagiotis Traganitis

Valtech Mobility – Detroit, Safety Team: Pedestrian Crossing Awareness Service

Valtech Mobility, established in 2018 through a collaboration between Volkswagen Group and Valtech GmbH, focuses on enhancing vehicle intelligence. Their new project aims to leverage technology to enhance pedestrian safety, particularly for individuals using smartphones.

Our mission is to contribute to the creation of intelligent solutions for the future of driving. We closely collaborate with Valtech to ensure that our products are not only useful but also continually improving. Imagine this scenario: individuals often remain engrossed in their phones while waiting at crosswalks. To facilitate their safe crossing, we are enhancing a smartphone app called the Smart Crosswalk Assistant. This app functions as a helpful companion, notifying users when it is safe to cross. Using the phone, the app recognizes when someone is waiting to cross, checks the traffic signals, and sends a notification to the user, indicating that it is safe to proceed. This way, even if people are engrossed in their phones, they won’t overlook the signal to cross the road. In this manner, the application serves as a benefit not only to pedestrians navigating crosswalks but also to drivers, minimizing instances of pedestrians crossing when it is not safe, thereby improving traffic flow.

Michigan State University

Team Members (left to right)

Russel Moran

Commerce Township, Michigan

Jaden Hanold

Portage, Michigan

Jason Li

Grand Rapids, Michigan

Luke Stern

Cass City, Michigan

Daniel Grembi

Sterling Heights, Michigan

Valtech Mobility – Detroit, Safety Team

Project Sponsors

Mike Bush

Detroit, Michigan

Angela Fessler

Detroit, Michigan

Project Facilitator

Dr. Jeffrey Nanzer

Texas Instruments: System for Slope Measurement with Radar

Texas Instruments (TI) has been a leader in solving sensing challenges with radar for both industrial and automotive applications. TI began working on its mm Wave radar in 2009. This project achieved its initial goal of bringing affordable sensing to automobiles. The mm Wave is equipped with a high-resolution radar and uses a lower power architecture with the ability to endure strenuous environmental conditions.

Our team sought to solve a fundamental problem using a IWR6843 radar. How do we prevent a robot from falling off a cliff or sliding down an inclined plane? Sensors such as cameras and lidar can be negatively impacted by adverse weather conditions like dense fog, smoke or rain. Radars operating at 60GHz have a larger wavelength and therefore can be more reliable in these weather conditions. Radars operate by transmitting radio waves that will reflect off a surface and then be received by the radar.

We worked to design and build a radar-based system using the IWR6834 and DCA1000 to accurately measure the slope of an inclined plane ahead. The design includes a structure to be able to modify the slope of the inclined plane ahead, a radar and a screen to display the measured slope. The design utilizes only one radar to measure a range of angles. It is mobilized by a servo to adjust its angle and find the optimal position for slope measurement. An algorithm was developed to convert the data into a slope estimate. This system can extend ahead of the robot and successfully measure the slope so a robot can avoid sliding down the slope. Our radar system provides a solution that TI can use for applications that require ground travel.

Michigan State University

Team Members (left to right)

Sterling Spaccarotella

Miami, Florida

William Nimtz

Waterford, Michigan

Megan Arnold

Sterling Heights, Michigan

Prasanth Peddireddy

Troy, Michigan

Mavrick Baho

Sterling Heights, Michigan

Texas Instruments

Project Sponsor

Anil Mani

Dallas, Texas

Project Facilitator

Dr. Premjeet Chahal

MSU Nondestructive Evaluation (NDE) Laboratory: Aerial Drone for Next Generation NDE

Nondestructive evaluation (NDE) is a field that involves detailed quantitative inspections of objects without permanently changing or damaging the structure(s) and/or object(s) of interest. NDE ensures the safety and proper functionality of critical infrastructures in the construction, energy, automotive, and aerospace industries.

The MSU NDE Laboratory focuses on designing and developing innovative sensors and monitoring systems to assess the structural integrity of various parts and components. The evaluation of parts includes internal and external flaw detection, flaw thickness measurements, and the analysis of the part or components’ material composition.

This project involves implementing a workflow for a manually controlled Autel Evo II Pro v3 aerial drone that will be mounted with a magnetic flux leakage (MFL) sensor developed by the MSU NDE Lab and a purchased Raspberry Pi.

The workflow consists of multiple stages, starting with reconstructing a computerized 3D model from 2D images of the area/ structure of interest. The 2D images will be obtained from the drone and its sensors. This is done using the open-source Meshroom software.

The data acquisition stage involves acquiring infrared imaging of the complete target structure and taking MFL readings in regions where damage is suspected. The data processing stage entails overlaying infrared imaging on top of the 3D reconstruction using the CloudCompare software.

Lastly, the evaluation of the structure will be done through statistical analysis, comparing the infrared measurements and the MFL sensor measurements. The combination of this acquired data will suggest the presence of defects, their location, and will provide accurate and detailed measurements for the suspected defects.

Michigan State University

Team Members (left to right)

Krish Chiwhane

Novi, Michigan

Yida Yang

Nanchang, China

Sara Tatreau

Grand Rapids, Michigan

Conner Grant

Ludington, Michigant

Kalyn Vanwormer

DeWitt, Michigan

Pramod Prahlada

Novi, Michigan

MSU Non-Destructive Evaluation (NDE) Laboratory

Project Sponsors

MSU Department of Electrical and Computer Engineering

East Lansing, Michigan

MSU Nondestructive Evaluation (NDE) Laboratory

East Lansing, Michigan

National Science Foundation (NSF)

Alexandria, Virginia

Project Facilitator

Dr. Shaunak Bopardikar

MSU Nondestructive Evaluation (NDE) Laboratory: Robotic Arm Object Reconstruction for NDE

The MSU Nondestructive Evaluation (NDE) Laboratory focuses on developing sensors and systems for monitoring and evaluating structural integrity of parts and components. This includes collecting data on internal or external flaws, determining the precise dimensions of components, and determining material structure and composition. Currently, one of the NDE Laboratory’s primary methods of evaluation is a robotic arm with a laser distance sensor as an end effector. The goal of this system is for any component to be able to be scanned and evaluated by the robot in the testing area. Current drawbacks with this system include limited data from the laser sensor which cannot be reliably used to help improve the robot’s scanning path, inaccuracies in the robot’s programmed vs. actual movements due to its age, and stereo camera 3D imaging not providing consistent or accurate enough data for the precision evaluations NDE Laboratory wants.

Our team has been tasked with improving upon the NDE system’s functionality by integrating a new suite of sensors into the current system. This will include an Eddy current sensor, inclinometer sensor, and the required support modules to run these sensors such as a Raspberry Pi and DAQs. The Eddy current sensor in the form of a printed circuit board (PCB) will assist in conducting more precise NDE analysis and provide mapping data that can be used to improve the robot’s scanning path. The inclinometer will be implemented to generate precise positional and angular data of the robot’s end effector in order to solve the robot’s accuracy issues adhering to its scanning path while working in conjunction with an L-GAGE Laser sensor from the previous design team.

Our goal this semester is to deliver a working NDE analysis package that satisfies or exceeds the expected improvements to the current system’s pathing and scanning capabilities without compromising any of its other functionality.

Michigan State University

Team Members (left to right)

Nicholas DePolo

Milford, Michigan

Mateusz Moczulski

Richmond, Michigan

Ileana Kueber

St. Clair Shores, Michigan

Benjamin Griffith

Grand Rapids, Michigan

Max Van Wert

Canton, Michigan

MSU Non-Destructive Evaluation (NDE) Laboratory

Project Sponsor

Ciaron Hamilton

Lansing, Michigan

Project Facilitator

Dr. Oleksii Karpenko

MSU Solar Racing Team: MSU Solar Car Battery Management System

The goal of the MSU Solar Racing Team (SRT) is to design a car that not only runs on solar power, but races long distances. This requires careful balancing of the on-board batteries to allow the car to travel fast while using as little power as possible.

A Battery Management System (BMS) can aid in the regulating of charging and discharging. Additionally, the SRT requests live voltage and temperature measurements of each battery module, as well as the current of the overall system.

These measurements of voltage, temperature, and current are used to monitor the health of the batteries. The use of these values over time can prolong their lifespan.

The picture to the right is a representation of the proposed circuit design, with power lines in red, and data lines in blue. Each battery will have a dedicated voltage and temperature sensor, and one current sensor is placed in series. All of these sensors report to the main Integrated Circuit (IC). The IC then controls a capacitor bank, instructing it how to charge and discharge.

Electric vehicles available for purchase require thousands of battery modules and in turn, require sophisticated management. As the automotive industry moves away from fossil fuels and towards alternative energy, new and innovative techniques must be developed to manage electric energy.

Michigan State University

Team Members (left to right)

Brendan Somers

Nutley, New Jersy

Anne Marie Clinger

Brighton, Michigan

Turbold Ariunbold

Ulaanbaatar, Mongolia

Ben Leising

Jackson, Michigan

Jose Moises Hernandez Lopez

Lansing, Michigan

MSU Solar Racing Team

Project Sponsor

Samuel Rabick

East Lansing, Michigan

Project Facilitator

Dr. Mauro Ettorre

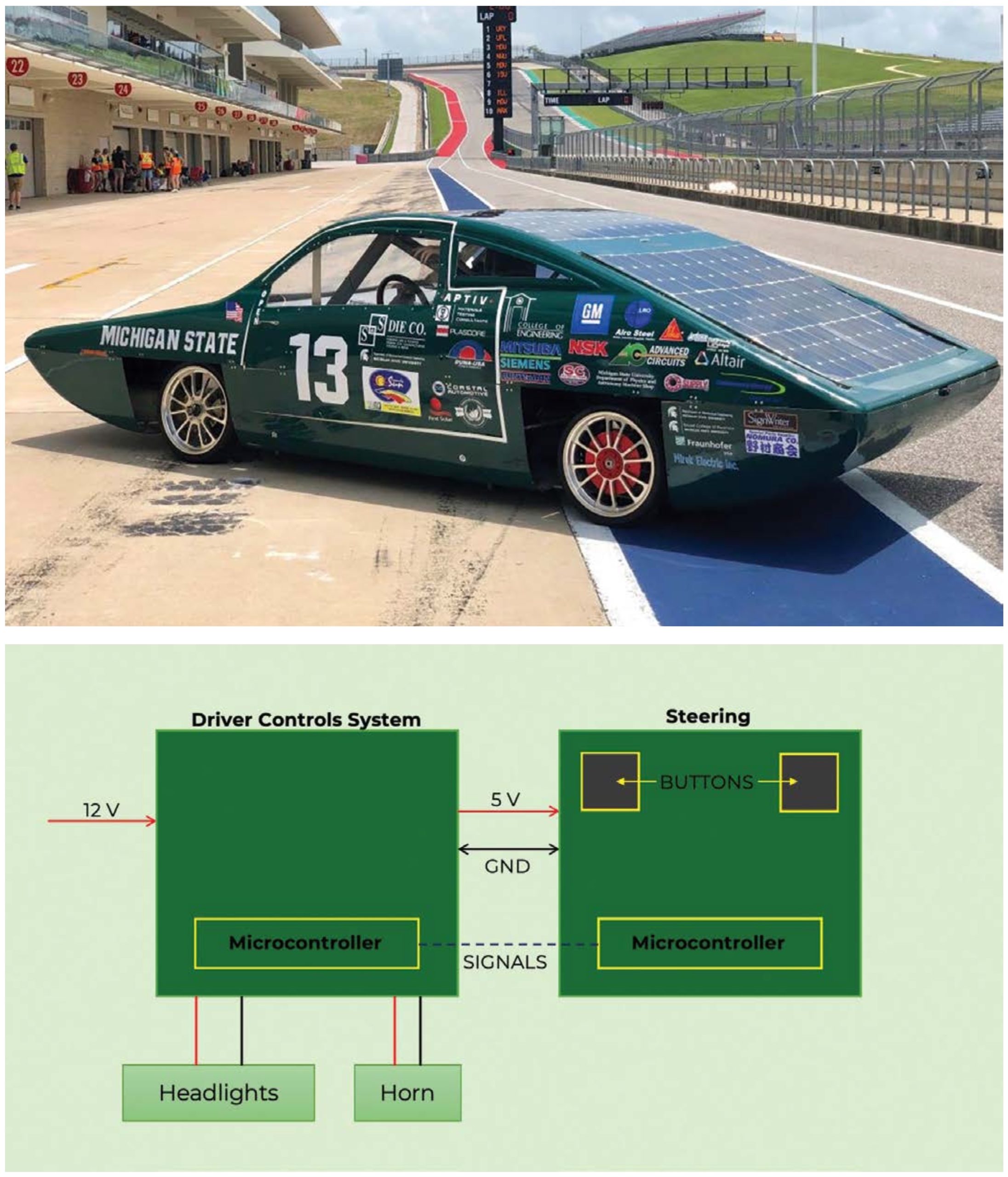

MSU Solar Racing Team: Solar Car Steering Wheel Serial Communication

The MSU Solar Racing Team is a student-led organization that focuses on designing, building, and racing a solar- powered vehicle. The team is comprised of students from many different majors, with the two biggest sub-teams being the Electrical and Mechanical Teams. Students from the Electrical Team mostly contribute by creating the printable circuit boards (PCBs) for different functions of the car and by using software to code these PCBs. Within the Electrical Team, there is the Driver Controls group which focuses on the design and integration of the Driver Controls Systems (DCS) board as well as the Steering board that serves as part of the human-machine-interface between the driver and the DCS.

Currently, the DCS board and the Steering board are connected electrically using parallel wires for each signal. As a result, there is an overwhelming number of wires being used. With the DCS board mounted inside the dash and the Steering board mounted onto the steering wheel, this makes the system more complex and adds weight once it has been integrated into the final design of the car.

To address this issue, a microcontroller can be installed onto the Steering board and serial communication can be used to send the analog signals as digital signals to the DCS board microcontroller. The new microcontroller would also replace the current Arduino Teensy 4.1. It would have low power consumption and be a low-cost option that could end up being implemented onto other boards by the team after this project is completed. The DCS microcontroller would essentially serve the same purpose as it already does, which includes controlling the inputs and outputs that make various functions of the vehicle work. These functions would include, but not be limited to, headlights, turn signals, hazards, cruise control, and horn.

Michigan State University

Team Members (left to right)

Dauan Hendley

Detroit, Michigan

Zainub Larji

Canton, Michigan

Emily Koles

Ortonville, Michigan

Varsha Rajagopalan

Dubai, United Arab Emirates

Peyton Nagher

Oxford, Michigan

MSU Solar Racing Team

Project Sponsor

Samuel Rabick

Kalamazoo, Michigan

Project Facilitator

Dr. Matthew Hodek

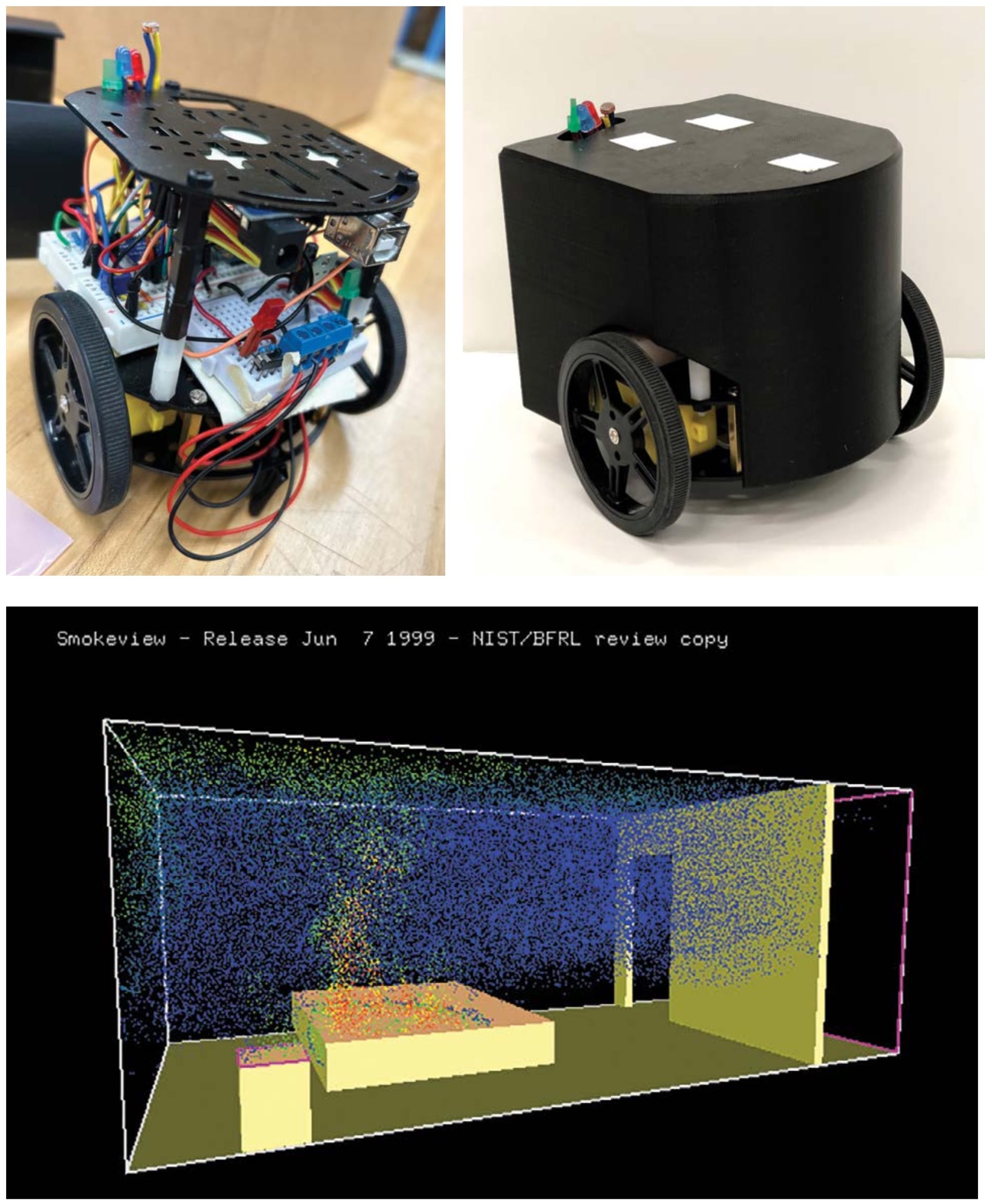

MSU D-CYPHER Lab: Design of Hardware-in-the-Loop Fire Simulator

Fire management is a serious contemporary issue. Whether it is a wildfire sparked by lightning or a housefire caused by faulty wiring, it is a tragedy for those involved and a municipal responsibility to extinguish, as swiftly and as effectively as possible.

The National Institute of Science and Technology (NIST) has created a Fire Dynamics Simulator (FDS) to model and simulate the fluid dynamics of fire and its mitigation, as well as Smokeview (SMK) to visualize these simulations. These are outstanding tools for analyzing the nature of fires and how they can be suppressed. As is, however, these tools cannot interface with real, physical robots to act out the firefighting case studies.

This is where hardware-in-the loop (HIL) comes in. HIL is a known testing method that sends signals from a controller to hardware to simulate and test software, thus making sure the controller is sending the correct signals. National Instruments describes HIL as a technique to “trick” the controller into thinking it is sending signals to a fully assembled system, even though it is only being sent to a small, simple piece of the assembled system.

By adding real-time simple robots to receive signals from the FDS simulation, our team and the D-CYPHER Lab are creating an HIL system that allows for realistic testing of different algorithms for suppressing fires. Being able to investigate simulated firefighting strategies is valuable as is it costly, ineffective, and often unfeasible to start real fires to do so otherwise.

Our team is bringing this important project to its next operational level. The goal of our project is to develop an HIL system that can interface a full team, or “swarm” of robots with the NIST FDS simulation software. Developed software will monitor physical positions of multiple robots and relate them to positions within the FDS simulation, then activate application of simulated fire retardant. Strategies to extinguish intense, multiple, or moving fires can now be explored.

Michigan State University

Team Members (left to right)

Alayna Schumaker

Canton, Michigan

Nick Fedewa

Byron Center, Michigan

Najiha Jaigirdar

Sterling Heights, Michigan

Doriana Vuljaj

Madison Heights, Michigan

MSU D-CYPHER Lab

Project Sponsor

Vaibhav Srivastava

East Lansing, Michigan

Project Facilitator

Dr. Virginia Ayres

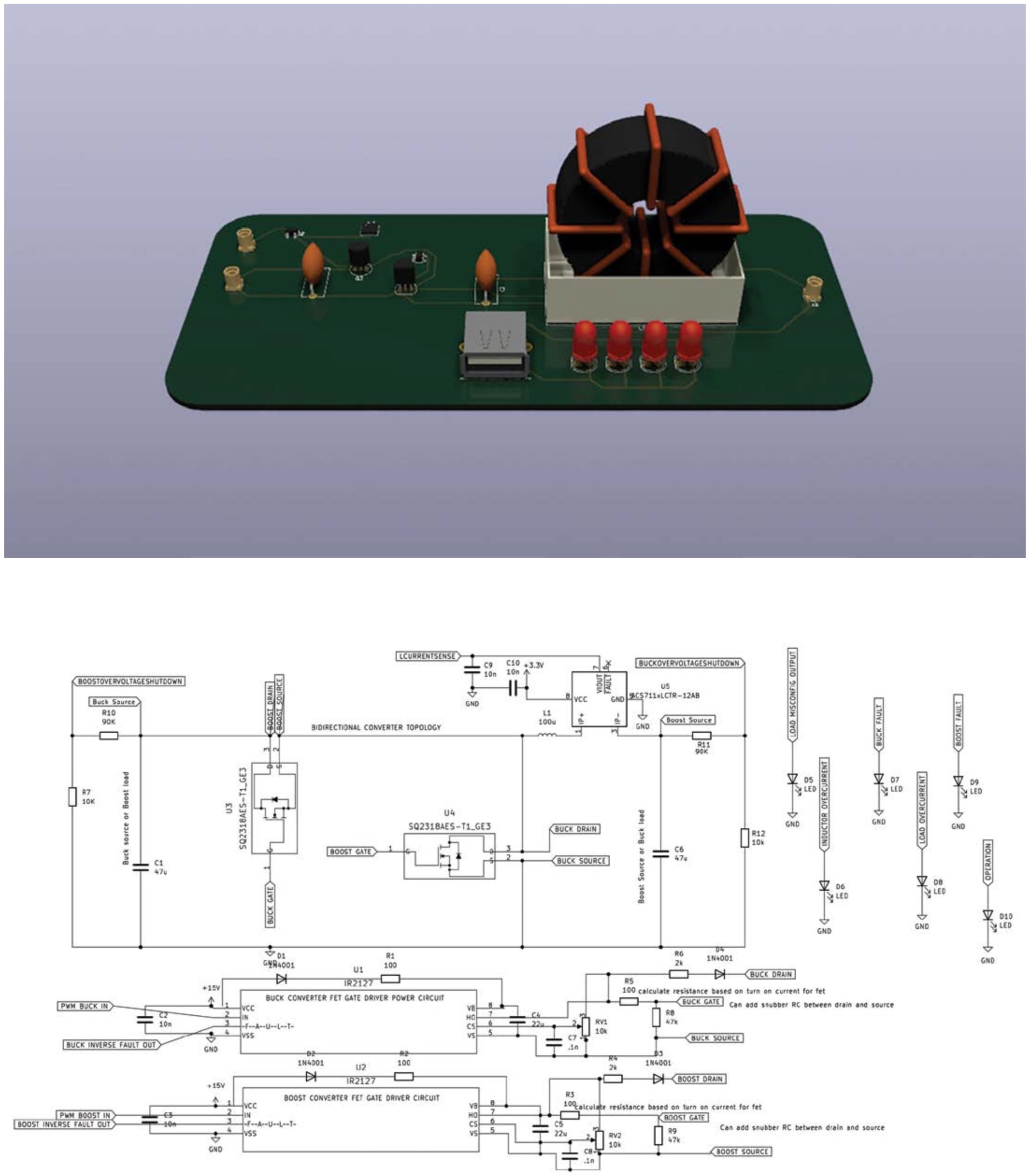

MSU Department of Electrical and Computer Engineering: 24W DC-DC Converter

Michigan State University is home to one of the top engineering programs in the state, providing a quality education to over six thousand undergraduate students every year. MSU relies on various laboratory-based learning experiences to maintain this level of academic quality, and so that students are able to see the conceptual knowledge they learn in their lectures applied in practice.

To better facilitate student learning and maintain the high academic standards here at MSU, the Department of Electrical and Computer Engineering is looking to construct a DC-DC converter to be used in various power systems labs for demonstrating and teaching buck and boost operation.

As always, safety is the first priority, especially in a laboratory setting, so the converter will have redundant overcurrent and overvoltage protections, as well as a misconfiguration shutdown, since it is highly likely for things to be assembled incorrectly.

With student learning being the main goal of the project, component accessibility is a high priority; all components will be clearly visible and labeled such that students can easily identify and interact with them. Additionally, certain signals, such as input/ output voltages, input/output currents, and inductor current, will be made easily available for display on an oscilloscope.

The physical implementation of the circuit will consist of a PCB enclosed in a 3D-printed case. Physical knobs and buttons will be used to provide user inputs alongside a software interface, which can override the physical controls when connected.

The goal of this project is to design, build, and test a 24W DC-DC converter, with a user adjustable switching frequency, that is capable of being operated in both buck and boost mode, and can accept a 12V input, with a maximum output of 24V.

Michigan State University

Team Members (left to right)

Ben Torok

Mason, Michigan

Jake Cabana

Holland, Michigan

Ben Schuchardt

Rockford, Michigan

Manan Patel

Canton, Michigan

Douglas Bombard

Rochester, Michigan

MSU Department of Electrical and Computer Engineering

Project Sponsor

Matthew Meier

East Lansing, Michigan

Project Facilitator

Dr. Woongkul Lee