MSU Formula SAE/Tesla: Battery Management System

MSU Solar Racing Team: Active Cell Balancing Battery Management System

MSU Solar Racing Team: Field Oriented Control for Solar Motor Inverter

Our Next Energy (ONE): Battery Cell Simulator

Fraunhofer USA: Microwave Detector & Photodiode Safety Interlock

MSU Bikes Service Center: MSU Bikes Green Box

Great Lakes Crystal Technologies: Measuring Diamond NV Center Charged States

MSU IPF/Sartorius/Consumers Energy: Big Data Analysis for Efficiency in Utility Generation

Facility for Rare Isotope Beams: SRAM-based Dosimetry for Heavy Ion Detection

Facility for Rare Isotope Beams: Variable Energy Degradation Stage

Nondestructive Evaluation Laboratory/NSF: Robotic Arm Object Reconstruction for NDE

Nondestructive Evaluation Laboratory/NSF: Aerial Drone for NDE Applications

MSU Department of Electrical & Computer Engineering: Scaled Down Autonomous Bus with Self-Parking Ability

MSU Smart Microsystems Laboratory: Scaled Teleoperated Vehicle for Smart Vehicle System

MSU Smart Microsystems Laboratory: Visual Inertial Odometry For Underwater Laboratory

MSU Diamond Laboratory: Diamond Plate Thickness Measurement

MSU Department of Electrical & Computer Engineering: Wirelessly Powered Backup Camera

Michigan State Biomedical Engineering: Wind Tunnel for Molecular Communication

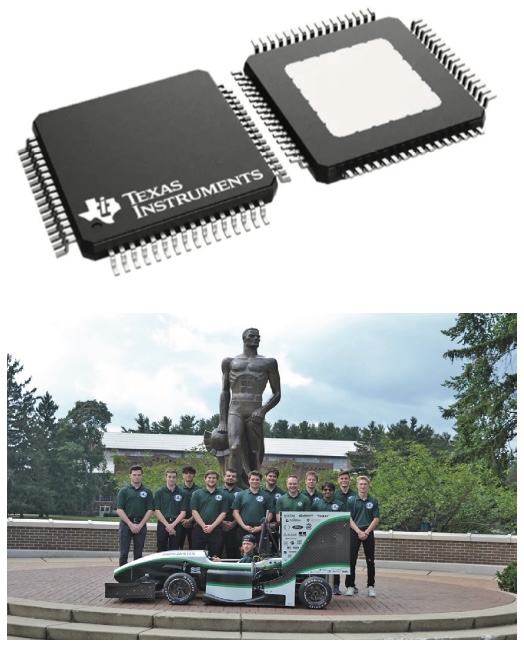

MSU Formula SAE/Tesla: Battery Management System

The global objective for this project is to assure safe operation while reducing cost and packaging issues by implementing the BMS board(s) for Michigan State University’s new Formula SAE electric racecar. The BMS board(s) design must be capable of reading sensors’ inputs, cell balancing, and being integrated into the racecar’s data acquisition system. These specific tasks include Select Battery Monitoring (BM) chip, select microcontroller, design sensor input circuitry, and design I/O needed for system integration.

To reach the objectives above, the BMS board(s) and the vehicle’s battery pack must be defined. The battery pack will consist of an assembly of Li-ion cells that will be managed from the BMS by monitoring temperature and voltage to ensure the safety of the battery cells, the vehicle, and personnel. A battery pack and sensors are components that will interact directly with the BMS board(s). The battery pack will consist of Li-ion cells used to power the vehicle’s EV powertrain. The sensors used are temperature and voltage sensors. The temperature sensors are able to measure the temperature of individual cells while the voltage sensors measure the voltage of each individual cell.

To determine if the objectives of the project have been met, testing and verification of both the hardware and control system will be conducted. Test PCBs of the BMS board(s) will be created to verify that every component is working as expected and meets the design requirements. A final board will then be created with all of the required components. When test benching is completed, the BMS can be implemented on the team’s vehicle. More testing will occur with various other sensors to ensure the battery pack and BMS are operating safely and correctly.

With the correct selection of components, effective and efficient programming, and rigorous testing, the BMS would allow the battery pack to deliver power safely.

Michigan State University

Team Members (left to right)

Yuxiang Su

Zhejiang, China

Byungchan Go

Seoul, Republic of Korea

Mason Gates

Saginaw, Michigan

Sam Evans

Frankenmuth, Michigan

Jack Wegh

Barrington, Illinois

Michael Stevenson

Highland, Michigan

MSU Formula SAE/Tesla

Project Sponsors

Gary Cloud

East Lansing, Michigan

Tianyu Ni

San Jose, California

Project Facilitator

Dr. Hayder Radha

MSU Solar Racing Team: Active Cell Balancing Battery Management System

This project’s purpose is to develop a Battery Management System, also known as a BMS for the Michigan State Solar Car Racing Team. Over the years, the Michigan State Solar Racing Team used BMS to implement passive cell balancing. In this project, one of our major goals is to include active cell balancing so that the sponsor may reap its benefits.

This project is divided into two major groups: hardware and software. The hardware aspect of this project includes the design and printing of a PCB along with the hardware needed to achieve active cell balancing and the ability to accurately read the voltage and temperature of the modules and the battery pack current. The software aspect of this project includes the ability to collect the data such as voltage, current and temperature and send that information via a control area network (CAN) line. Collected measurement will display any faults using the CAN line. Finally, the software should also be able to support active cell balancing.

Michigan State University

Team Members (left to right)

Abdullah Soofi

West Lafayette, Indiana

Howard Hu

Grand Rapids, Michigan

Gautham Kanakasabai

Canton, Michigan

Jose Garcia-Jimenez

Holland, Michigan

Mohammed Nasir

East Lansing, Michigan

Hamdan Alsaif

Baldwin, New York

MSU Solar Racing Team

Project Sponsors

Prerana Gunda

Farmington Hills, Michigan

Dashiel Matlock

Saint Joseph, Michigan

Project Facilitator

Dr. Mauro Ettorre

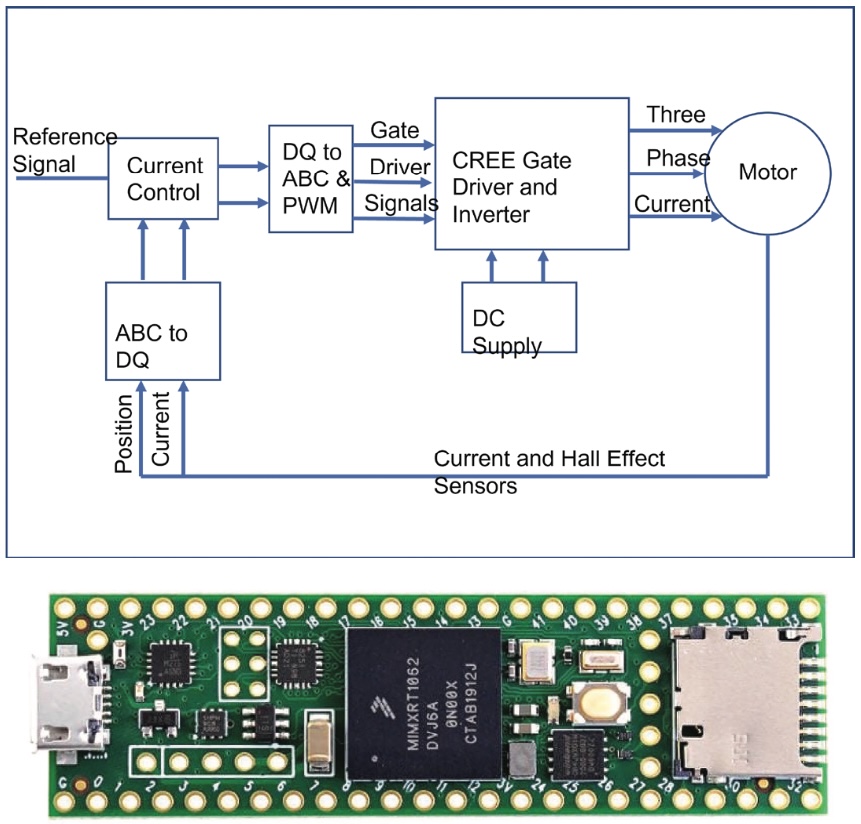

MSU Solar Racing Team: Field Oriented Control for Solar Motor Inverter

We were tasked by the MSU Solar Racing Team to design and code a Field Oriented Control (FOC) Motor Inverter for driving three-phase solar motor inverters. To do this, the team built a functional FOC code block diagram and implemented this with the Teensy Microcontroller for utilization on the Motor Inverter. The team utilized the Motor Inverter from Fall 2022, as well as various electrical components we deemed fit to use. Additional hardware that was needed was purchased by Michigan State.

The design implemented was able to run and drive a motor using the controller provided, through the application of Arduino software, resulting in our final design precisely controlling the torque output of the motor. It was also able to accurately read the phase and speed of the motor’s rotation, as well as power consumption. The final design was also created with the sizing of each component used in mind.

The Michigan State Solar Racing Team specified several requirements that our design successfully fulfilled. Aside from the major tasks outlined above, the controller was an efficient program that interfaced with the existing hardware design. Additional hardware was efficiently sized and durable enough to withstand any rugged or environmental conditions the solar car might encounter.

Michigan State University

Team Members (left to right)

Andrei Dogariu

Troy, Michigan

Henry Menigoz

Ontonagon, Michigan

Hana Yantus

Macomb, Michigan

Jason Clark

Beal City, Michigan

Mitchell LeGrave

Norway, Michigan

Kyle Heverly

Bloomfield, Michigan

MSU Solar Racing Team

Project Sponsor

Project Facilitator

Dr. Matt Meier

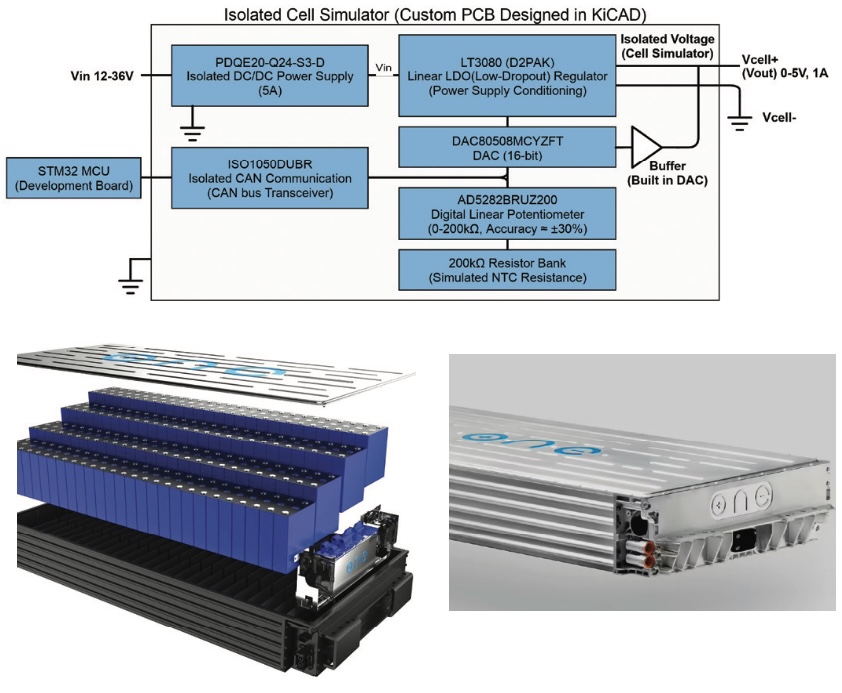

Our Next Energy (ONE): Battery Cell Simulator

Founded in 2020, Our Next Energy (ONE) is a Michigan-based energy storage technology company headquartered in Novi, Michigan. Our Next Energy seeks to accelerate the transition to sustainable vehicle electrification by engineering innovative energy storage solutions.

ONE is developing HV battery packs that use strings of Li-Ion based high-capacity cells. The high voltage battery packs can have series string cells of up to 112 cells. All designs are done in-house at ONE.

This project will focus on the design and prototype of a compact Battery Cell Simulator for ONE’s development of HV battery packs. Using a simulated battery cell is a much safer option and is required for a majority of the development efforts. It enables the team to control the output voltage of the cell to perform testing on an HV Battery Management System (BMS).

An Isolated Controller Area Network (CAN) is used due to its ability to withstand adverse conditions of the communication of the protocol. This design has an optional NTC Thermistor simulator that can be included..

This project offers test engineers a safe option for development and calibration work via an external controller for the engineers at ONE. The build and parts costs for 5x modules remained under the assigned $500 budget. The fabricated modules are designed with a focus on desired SWaP-C (Size, Weight, Power, and Cost) optimization.

Engineering practices that help us achieve our design and fabrication goals of this project are attentive design planning considerations, organization, planning, and reflection. Standards that keep us safe include diligent software testing, safe electronics handling (ESD, ventilation, eye protection), and storage protocols.

Michigan State University

Team Members (left to right)

Jiafeng, Yu

Shanghai, China

Kylie Clink

Mason, Michigan

Andy Tom

Lansing, Michigan

Kyle Neid

Belleville, Michigan

Kyle Bandes

Warren, Michigan

Garrett Feinauer

Owosso, Michigan

Our Next Energy

Project Sponsor

Ashiful Khurashi

Novi, Michigan

Project Facilitator

Dr. Virginia Ayres

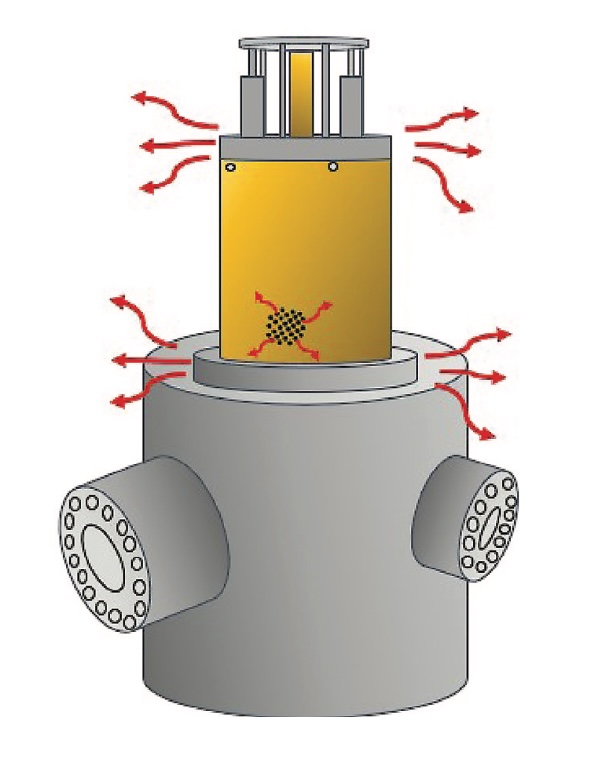

Fraunhofer USA: Microwave Detector & Photodiode Safety Interlock

The Fraunhofer USA Center for Coatings and Diamond Technologies, in partnership with Michigan State University, provides innovative R&D services based on its expertise in coating and diamond technology. The Chemical Vapor Deposition (CVD) process involves injecting a gas into a chamber while increasing the temperature. This high temperature causes a chemical reaction between the gas and substrate, resulting in a thin layer to form on the substrate. This CVD process is used by Fraunhofer for diamond growth.

Due to the high levels of electromagnetic radiation and thermal energy involved in the CVD process, safety mechanisms are essential. Exposure to low levels of microwave radiation must be regulated when working within these environments.

The objective of this project is to create a sensor system capable of measuring microwave leakage and light intensity of plasma from the CVD reactors. To address microwave leakage, an RF detector in the form of a microstrip antenna (on a PCB) will measure the leaking microwaves. A photodiode will be used to read light intensity being emitted from the plasma within the reactor. The photodiode will act as an on/off interlock for the plasma.

The information collected by the sensors will be transmitted to a microcontroller which will convert the analog readings into digital signals and will be compatible with the communication bus currently being used by the Fraunhofer team. Safety interlocks for the entire system will then be implemented by their software team.

Michigan State University

Team Members (left to right)

Sibo Peng

Nanchong, China

Blake Evans

Northville, Michigan

Connor Kempisty

Howell, Michigan

Adam Giachino

Wixom, Michigan

Abel Hunegnaw

Chesterfield, Michigan

Fraunhofer USA

Project Sponsors

Travis Couzynse

East Lansing, Michigan

Robert Rechenberg

East Lansing, Michigan

Project Facilitator

Dr. Ming Han

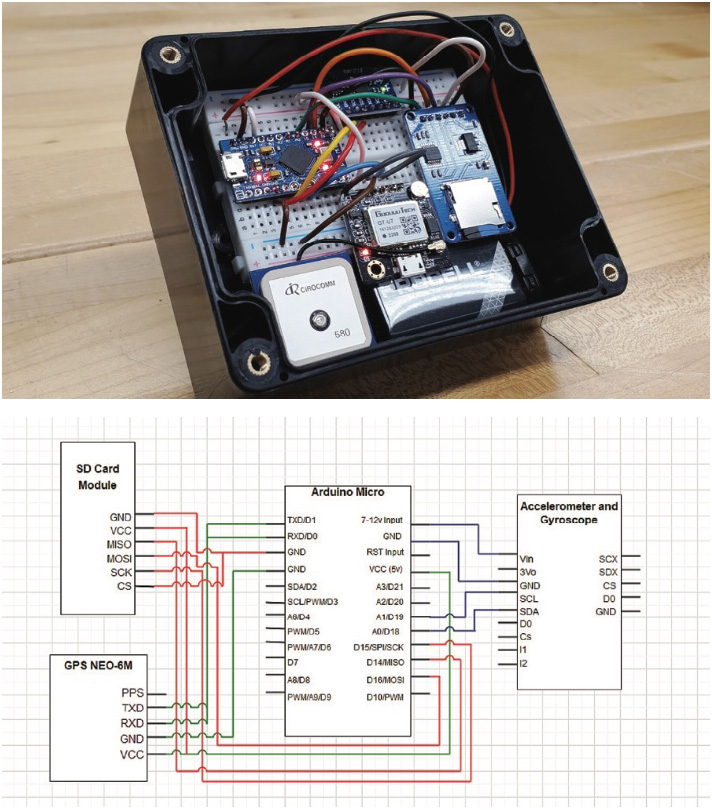

MSU Bikes Service Center: MSU Bikes Green Box

In 2003, the MSU Bikes Service Center started as a volunteer-run project dedicated to promoting the use of bikes on MSU’s campus as both an environmentally-friendly as well as physically-fulfilling mode of transportation. Later, in 2006, the organization began to receive funding from Michigan State University, leading to the opening of its current location on Farm Lane.

With Michigan State University having such a dense population and the high volume of bikes, electric scooters, and other micro-mobility modes of transportation present at any given time, many small-scale accidents occur across campus, despite the best efforts of all involved. To assist in further minimizing these accidents, our team is working with the MSU Bikes Service Center to create a device that will help detect these incidents on campus.

The MSU Bikes Green Box is a project aimed at creating small, easily mountable devices that, with the riders’ consent, can track users and inform them of their vehicle’s acceleration at any given time while in transit. The box contains an Arduino Micro microcontroller and sensors, in particular, an accelerometer, gyroscope, and GPS module, that all will provide the information required to identify both when a crash occurs and where it did occur. Furthermore, our group developed a data processing program that will properly identify different kinds of incidents such as near-miss, minor, or major accidents.

This data collection is being performed in the hopes that it can be utilized by the university to further safeguard students and faculty that choose to utilize micro-mobile devices. Our box will assist in locating accident hotspots around campus. This, in turn, can be utilized to determine what issues may be present in the area’s layout and how these issues can be used to improve bike safety.

Michigan State University

Team Members (left to right)

Kyle Heslop

Novi, Michigan

Collin Faeth

Brighton, Michigan

Andrew Merriman

Dexter, Michigan

Jake Ryba

Novi, Michigan

Karson Mientkiewicz

Allen Park, Michigan

Victor Faletti

Birmingham, Michigan

MSU Bikes Service Center

Project Sponsor

Tim Potter

East Lansing, Michigan

Project Facilitator

Dr. Sunil Chakrapani

Great Lakes Crystal Technologies: Measuring Diamond NV Center Charged States

Nitrogen-doped, lab-grown diamonds have nitrogen vacancy (NV) center point defects, in which electrons can become trapped. When these electrons relax following excitation, they emit photoluminescence (PL) intensity spikes at certain wavelengths. In our case, a 515 nm beam will excite these electrons, leading to PL intensity spikes at 575 nm and 637 nm, which correspond to NV- and NV0 centers, respectively. We can measure these PL spikes to obtain an NV-/NV0 intensity ratio. An optical set-up will be created to measure these spikes. A 515 nm laser will be directed at a diamond sample enclosed in darkness. Optical bandpass filters will filter out the incident 515 nm wavelength, as well as any background PL intensity at wavelengths other than 575 nm and 637 nm. At room temperature, background PL intensity can be quite high, leading to increased SNR, which may obscure spikes, creating a signal processing challenge. The filtered diamond response will be captured using a detector, either an ocean optical spectrometer or a CCD camera. We will then perform image analysis and signal processing on the CCD camera output to isolate intensities and determine the corresponding wavelength of light. This data will then be used to calculate NV-/NV0 intensity ratios, which will allow for the characterization of point defects on the diamond.

Michigan State University

Team Members (left to right)

Mijan Ahmad-Nizam

Grand Haven, Michigan

Maximus Sese

Utica, Michigan

Adesh Gondara

Farmington Hills, Michigan

Ryan Kunkel

Saugatuck, Michigan

Derek Luzano

Milan, Illinois

Great Lakes Crystal Technologies

Project Sponsors

Ramon Diaz

East Lansing, Michigan

Paul Quayle

East Lansing, Michigan

Project Facilitator

Dr. Qi Hua Fan

MSU IPF/Sartorius/Consumers Energy: Big Data Analysis for Efficiency in Utility Generation

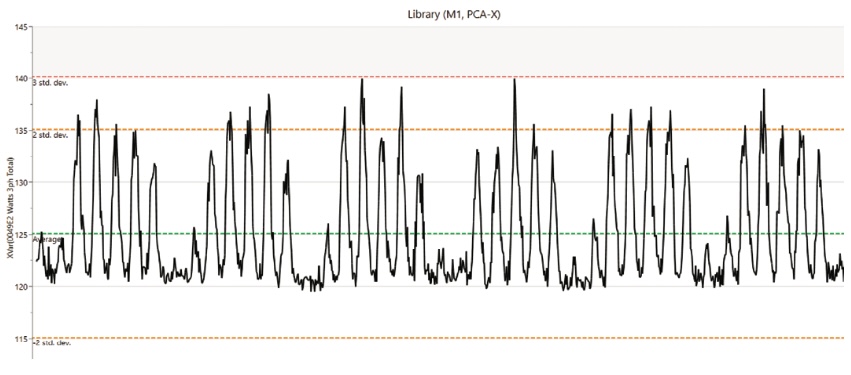

Michigan State Infrastructure Planning and Facilities has been providing power and heating for MSU through the T. B. Simon Power Plant since 1965; various other plants throughout the school’s history provided this service before the T. B Simon plant’s construction. Today almost all the power and heat used around campus is provided by this power plant’s multiple generators or other energy sources on campus, such as solar panels. Dedicated generators were initially put in place to capitalize on a byproduct of steam heating, a far safer alternative to central coal or wood stoves in buildings, and allowed power generation on top of campus-wide heating for minimal extra cost. However, as this operation has grown, so has its price. $20-$40 million is spent annually on fuel to power these generators and provide heating to Michigan State’s campus.

While there is no way to cut this entirely, the goal of this project is to lower these costs by about 1%, which, while relatively small, would save the university around a quarter of a million dollars every year. Using SIMCA, a data analysis software provided by Sartorius, as well as a data historian recording millions of data points related to power use and generation by the T. B. Simon Plant, finding inefficiencies in the delivery of power to various on- campus facilities should be possible. Variables measured by the historian will be compared and analyzed for underlying trends after Principal Components Analysis (PCA) is performed using software. Comparisons will be made through scores and loading plots, as well as finding correlations between related variables. When a trend is found, we will perform research, generate models, and suggest reasonable changes to the sponsors and university. These changes are to be tested and validated by the various qualified engineers employed by the university for the T. B. Simon plant.

Michigan State University

Team Members (left to right)

Adam Sloan

Grosse Pointe, Michigan

Tara Younessi

Northville, Michigan

Ryan Mozariwskyj

Sterling Heights, Michigan

Hunter Gendregske

Saginaw, Michigan

Cobby Baffour-Awuah

Lansdowne, Pennsylvania

MSU IPF/Sartorius/ Consumers Energy

Project Sponsors

Greg Casee

Northampton, Pennsylvania

Nathan Verhanowitz

Okemos, Michigan

Project Facilitator

Dr. Daniel Morris

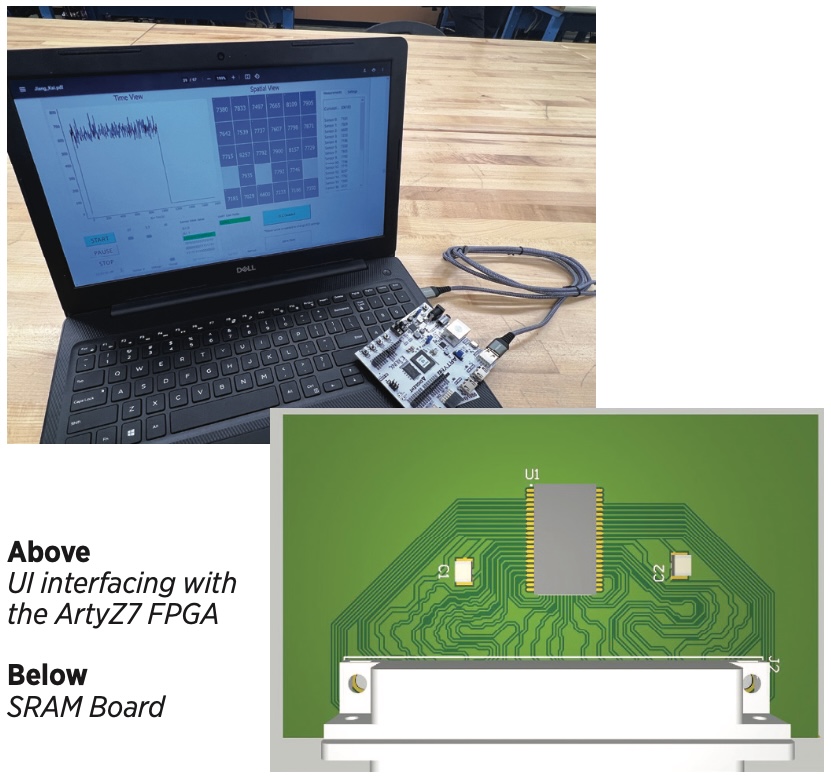

Facility for Rare Isotope Beams: SRAM-based Dosimetry for Heavy Ion Detection

In memory devices, radiation can cause soft errors in the form of bits flipping out of turn. This is called a single event upset. Studying these single event upsets can aid in many ways pertaining to technology. Understanding the causes and effects of this single event upset can help in mitigating these errors. It can also allow us to compensate for single event upsets in environments that are conducive to causing them, which is being researched by many different groups. Research has been conducted into reducing single event upsets to ensure the integrity of memory devices in environments like space or high radiation environments. However, there is another potential use of studying the effects of radiation on single event upset. Doing so can potentially enable detection of the radiation, as well as potentially measuring it based on the frequency of the upsets. This avenue of research is something that MSU’s Facility for Rare Isotope Beams (FRIB) is interested in pursuing through this project. FRIB is a world-class scientific user facility for the US Department of Energy Office of Science and is located on MSU’s campus. Due to its powerful, in-house isotope accelerator, much of the leading research surrounding radiation and heavy-ion particles has been performed at FRIB.

The main goal of the project as stated above is to develop an SRAM FPGA interface that acts as a dosimeter. For the purposes of this project, only the SRAM and FPGA are to be developed, with the testing of this interface as a dosimeter being done outside of the scope. The bulk of this project, therefore, pertains to developing an interface for the FPGA to be able to track bit flips in the SRAM, such that when the SRAM is given a set read/write cycle, the FPGA should be able to track and mark when a single event upset occurs, i.e., where the bits flip when they should not.

Michigan State University

Team Members (left to right)

Andrew Maciejewski

Northville, Michigan

Shashank Gowda

Bloomfield Hills, Michigan

Austin Fink

Lexington, Michigan

Ethan Galdikas

Northville, Michigan

Umar Hassan

Farmington Hills, Michigan

Mehdi Al Saffar

Okemos, Michigan

Facility for Rare

Isotope Beams

Project Sponsors

Scott Cogan

East Lansing, Michigan

Steven Lidia

East Lansing, Michigan

Project Facilitator

Dr. Peng Zhang

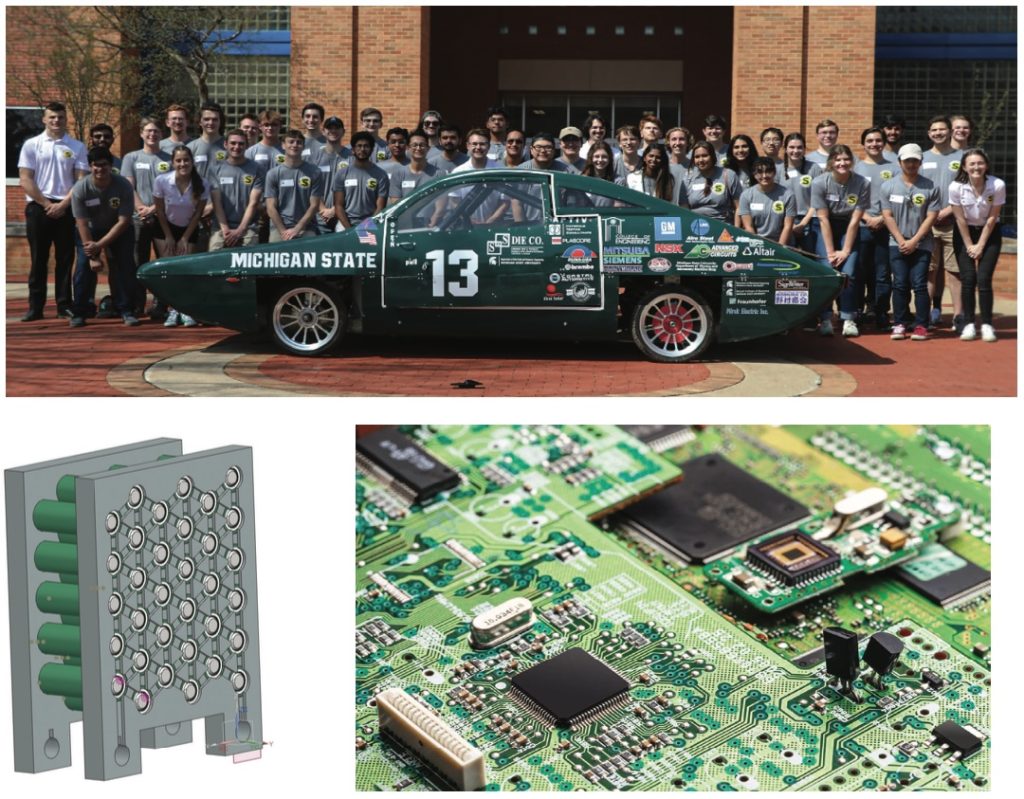

Facility for Rare Isotope Beams: Variable Energy Degradation Stage

The Facility for Rare Isotope Beams (FRIB) strives to provide users with on-time delivery of ion beams and accurate characterization of beam parameters. Linear Energy Transfer (LET) energy deposition studies must be conducted to study the impact of Single-Event Effects (SEE).

SEE occurs when a single energetic particle collides with an electronic device and causes a change to its operational threshold(s). SEE can impact space-flight-qualified electronics immensely, leading to incidents that range from annoying system responses to catastrophic system failures, for example, satellites falling out of orbit.

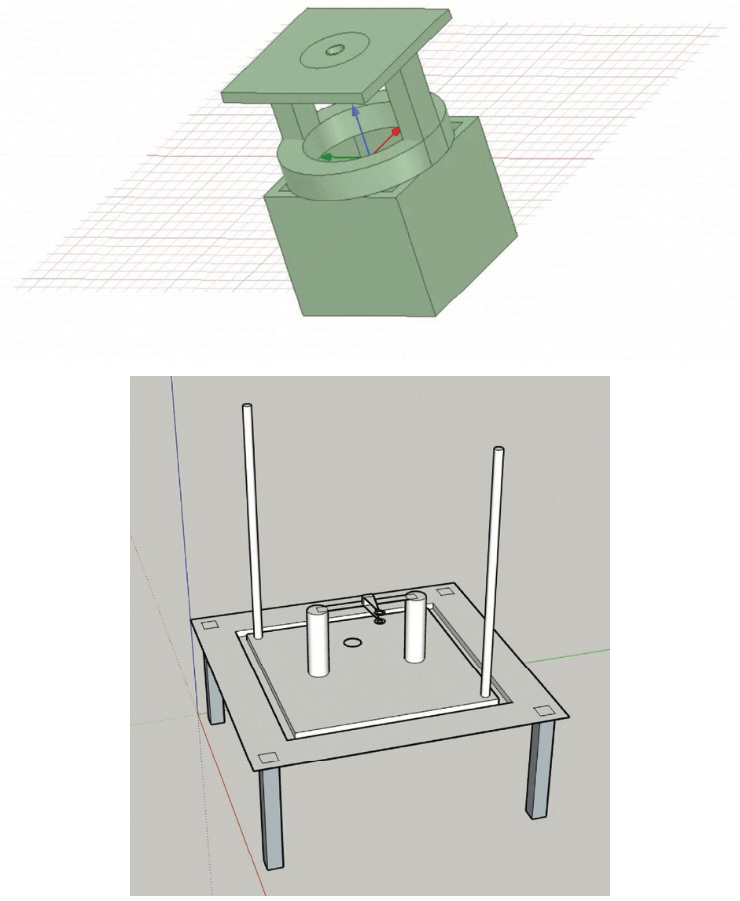

During beam path firing, controlled LET levels can be accomplished using specific thicknesses of metallic foils that degrade beam intensity until it reaches a maximum device damage threshold. An optimal device to switch between metallic foils has yet to be created.

This project is to design and build a remotely controlled, motorized stage with encoder readback to place one of several energy- degrading foils in the beam path. The stage is made of aluminum, a lightweight material. The stage contains clamps that attach to the stationary beamline stage. The stage has a sliding frame that will hold four foils, which are held in place by individual brackets. The sliding frame moves along the x-plane into four set positions and a set home position by a linear actuator. The linear actuator is controlled remotely by an Arduino. The Arduino interacts with a user interface tablet to select the foil frame position.

For this project, our goal is to test and demonstrate that the motorized stage can have movement repeatability. With the successful completion of this project, the stage will be incorporated with an existing user beamline at FRIB.

Michigan State University

Team Members (left to right)

Alex Dubinski

Canton, Michigan

Nicholas Apap

Milford, Michigan

Parfait Iradukunda

Grand Rapids, Michigan

Brooke Osterkamp

Novi, Michigan

Patrick Bates

Lincoln, Michigan

Madeline Stafford

Muskegon, Michigan

Facility for Rare

Isotope Beams

Project Sponsors

Steven Lidia

East Lansing, Michigan

Francisco Pereira de Figueiredo

East Lansing, Michigan

Abe Yeck

East Lansing, Michigan

Project Facilitator

Dr. Virginia Ayres

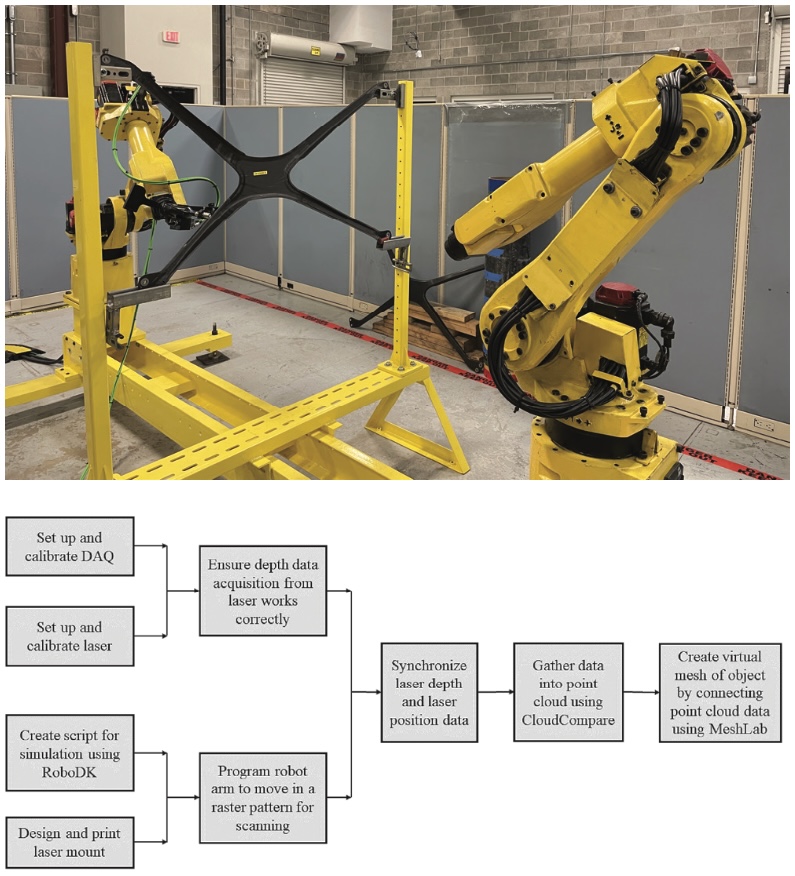

Nondestructive Evaluation Laboratory/NSF: Robotic Arm Object Reconstruction for NDE

Nondestructive evaluation (NDE) consists of using non-invasive methods to analyze the structure of critical components or structures. NDE is used in any situation where it is desirable or necessary to determine the condition or structural integrity of a part or structure without damaging or disassembly. NDE is necessary in several industries such as automotive, aerospace, civil infrastructure and power.

Nondestructive testing is accomplished with the aid of a variety of external sensors that utilize ultrasound, light, magnetic fields, eddy currents, microwaves, X-rays, etc. to evaluate the surface or subsurface of the object being evaluated. Sensors are often mounted on robotic rigs which move the sensors over the object in a 2D plane for automation and consistency. Some parts, however, have complex geometries which do not allow for simple, pre- programmed movements to scan the entire surface. When evaluating objects with these more challenging geometries, it is desirable to use a robotic arm that can maneuver the sensor in 3D space around the surface of the object.

This project is to design and implement such a system to scan and reconstruct the surface of a complex-geometry object using a robotic arm with a laser distance sensor as its end effector in order to construct a computer model of the object. Additionally, the reconstructed model can be used to generate more accurate paths for the robotic arm so sensors with stricter range requirements can be deployed for further analysis of the part.

Michigan State University

Team Members (left to right)

Franklin Lopez

Grand Rapids, Michigan

Sean Elworth

Chicago, Illinois

Gabrielle Lovett

Battle Creek, Michigan

Max Verboncoeur

Okemos, Michigan

Andy Fondaw

Rochester Hills, Michigan

Nondestructive Evaluation Laboratory/NSF

Project Sponsors

Ciaron Hamilton

East Lansing, Michigan

Oleksii Karpenko

East Lansing, Michigan

Lalita Udpa

East Lansing, Michigan

Project Facilitator

Dr. Lalita Udpa

Nondestructive Evaluation Laboratory/NSF: Aerial Drone for NDE Applications

Nondestructive evaluation (NDE) techniques are used to evaluate the integrity of critical structures in power, oil and gas, aerospace, and automotive industries. These techniques are important for detecting damage precursors and performing appropriate maintenance to ensure safe and continual operation. These techniques are realized with the help of sensor technology (ultrasound, light, eddy current, etc.) that are selected based on the material and geometry of test specimen.

The sensors that are developed in academic laboratories are often mounted on an x-y scanning gantry to generate a well-defined image of the sample defects. On a manufacturing floor, the sensors need to be mounted on a robotic scanning platform, which helps them navigate the varied situations. These robotic platforms help sensors reach places where it may be precarious for human operators to work, or even impossible due to space restrictions.

This project entails designing an aerial drone for inspecting large structures such as wind turbines, power plants, and building infrastructure. The drone will perform a series of motions, and collect a stream of 2D video, which will then be converted to a 3D model using Photogrammetry tools. Students can make use of commercially available parts like Pixhawk flight controller and suitable microcontroller for control and data acquisition.

The project will serve to advance the technology of drones in NDE applications. It will add an important capability to NDE systems, namely that of automatic scanning of larger structures with access limitations.

Michigan State University

Team Members (left to right)

Sam Gilliam

Grosse Ile, Michigan

Mitchell Youngerman

Troy, Michigan

Dan McDermott

South Lyon, Michigan

Sam Polym

Saint Joseph, Michigan

Chapin Ramseyer

Kankakee, Illinois

Jared Stross

Lake Orion, Michigan

Nondestructive Evaluation Laboratory/NSF

Project Sponsors

Ciaron Hamilton

East Lansing, Michigan

Oleksii Karpenko

East Lansing, Michigan

Project Facilitator

Dr. Lalita Udpa

MSU Department of Electrical & Computer Engineering: Scaled Down Autonomous Bus with Self-Parking Ability

Nondestructive evaluation (NDE) techniques are used to evaluate the integrity of critical structures in power, oil and gas, aerospace, and automotive industries. These techniques are important for detecting damage precursors and performing appropriate maintenance to ensure safe and continual operation. These techniques are realized with the help of sensor technology (ultrasound, light, eddy current, etc.) that are selected based on the material and geometry of test specimen.

The sensors that are developed in academic laboratories are often mounted on an x-y scanning gantry to generate a well-defined image of the sample defects. On a manufacturing floor, the sensors need to be mounted on a robotic scanning platform, which helps them navigate the varied situations. These robotic platforms help sensors reach places where it may be precarious for human operators to work, or even impossible due to space restrictions.

This project entails designing an aerial drone for inspecting large structures such as wind turbines, power plants, and building infrastructure. The drone will perform a series of motions, and collect a stream of 2D video, which will then be converted to a 3D model using Photogrammetry tools. Students can make use of commercially available parts like Pixhawk flight controller and suitable microcontroller for control and data acquisition.

The project will serve to advance the technology of drones in NDE applications. It will add an important capability to NDE systems, namely that of automatic scanning of larger structures with access limitations.

Michigan State University

Team Members (left to right)

Chris Baker

San Clemente, California

Charley Akers

South Lyon, Michigan

Brandon Cherry

Detroit, Michigan

Harry Cowan

Grosse Ile, Michigan

Maryann Kukla

Grosse Ile, Michigan

Keaton Mulcahy

Canton, Michigan

MSU Department of Electrical & Computer Engineering

Project Sponsor

Shaunak Bopardikar

East Lansing, Michigan

Project Facilitator

Dr. Vaibhav Srivstava

MSU Smart Microsystems Laboratory: Scaled Teleoperated Vehicle for Smart Vehicle System

The MSU Smart Microsystems Laboratory (SML), established in 2004, is dedicated to enabling smarter, smaller, integrated systems by modeling advanced control and design methodologies. Their research specializes in control, dynamics, robotics, and smart materials. With a current focus in autonomy, the MSU SML is dedicated to providing a solution to a safer, more reliable method of autonomous travel.

Our team has added to this effort; tasked with the job of developing a remotely human-driven scaled car to be used in a system of autonomous vehicles, all of which are aware of each other’s locations and park in the safest spot. Our vehicle is capable of being controlled and viewed from a PC over Wi-Fi, with first-person view front- and back-facing cameras for visual feedback.

With our developments, users will be able to gain knowledge of autonomous vehicles and their parking habits through a safe, simulated environment with human-like feedback. All vehicles are equipped to transmit data to a centralized computer system, where positional, velocity, and heading data are used to observe and interact with the autonomous environment.

To further simulate a human environment, the driver of our car will have a realistic first-person perspective view with a video stream of both cameras, along with an intuitive user interface to allow the driver to truly interface with a realistic driving system. Our simulation is easily expandible, with capability for a virtual reality environment through compatible cameras and a steering wheel with acceleration and deceleration pedals.

All programming was done in Python and C/C++ using the open-source Robot Operating System, ROS2 Galactic on the Linux distribution Ubuntu, with packages to support multiple IP camera transmissions.

Michigan State University

Team Members (left to right)

Fariz Azam

Okemos, Michigan

Ryan Young

Rochester, Michigan

Jack Vezmar

Marshall, Michigan

Da’Quan McClean

Lake Alfred, Florida

Christopher Braley

Midland, Michigan

MSU Smart Microsystems Laboratory

Project Sponsors

Xiaobo Tan

East Lansing, Michigan

Isaac Thompson

East Lansing, Michigan

Project Facilitator

Dr. Matt Hodek

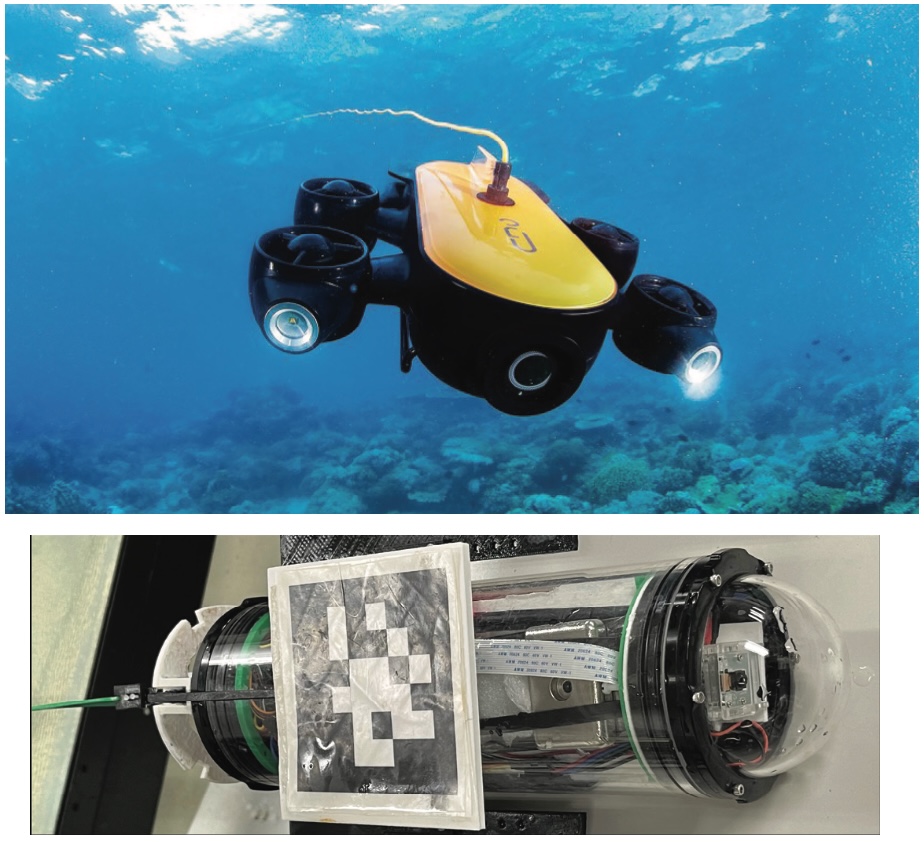

MSU Smart Microsystems Laboratory: Visual Inertial Odometry For Underwater Laboratory

Established in 2004, the MSU Smart Microsystems Lab researches the general areas of robotics, dynamics, control, mechatronics, and smart materials. The mission of the Smart Microsystems Lab is to merge advanced modeling, control, and design methodologies with materials and fabrications to enable smarter and smaller integrated systems. The focus of current research is on electroactive polymer sensors and actuators, bio-inspired underwater robots, and underwater mobile sensing.

Visual Inertial Odometry (VIO) is needed to help identify the precise location of the vehicle or device when the GPS signal is disrupted or not incorporated. This may happen when vehicles drive under bridges, or underwater robots dive in the ocean. VIO will use cameras that are built into the device to determine its position and orientation. The cameras will be used to scan the April Tags to receive the x-y coordinates. The information being analyzed will be processed within the software and a GUI will display the estimated location to the user.

Ultimately the final design will be capable of displaying a 3D model of the robot’s route error with an accuracy of 5% and a heading accuracy of 2%.

Michigan State University

Team Members (left to right)

Brian Alder

Clinton Township, Michigan

Dennis Hamilton

Howell, Michigan

Tommy Huynh

Caledonia, Michigan

Mohamed Saleh

Dearborn Heights, Michigan

Yan Yang

Guangdong, China

Letian Shi

Anhui, China

MSU Smart Microsystems Laboratory

Project Sponsors

Demetris Coleman

Birmingham, Alabama

Xiaobo Tan

Danyang, China

Project Facilitator

Dr. Selin Aviyente

MSU Diamond Laboratory: Diamond Plate Thickness Measurement

Michigan State University is home to one of the largest diamond growing facilities in the nation. This facility grows single crystal diamonds so well that special tools are needed to see the difference between one grown in the lab and one mined underground. These diamonds are being used for research with electrical components that require both a high degree of accuracy and an ohmic contact with other components. However, before being used in the components, the diamonds must be prepared accordingly.

One of the many processes involved in preparing the diamond for use is polishing the diamond so that the surface is smooth, and the diamond will maintain a solid connection with other components. In this polishing, however, a small portion of the diamond’s thickness is lost. As the quality of the diamond varies, the amount of thickness removed changes. Therefore, it is important to know how much has been removed. As the diamond is glued onto a stand before polishing, the engineers are forced to unglue the diamond plate to take any measurements. This process is tedious and adds significant time to the polishing process.

To resolve the problem, our team designed a capacitance circuit and holder, which is used to digitally display the thickness of a diamond plate. With this product, diamond plate polishers can determine how much substance is being polished off of the diamond without the need to remove the glue, measure with calipers, then repeat. Our system works as a simple device that takes a capacitance measurement of the diamond substrate and calculates the diamond plate thickness as determined by a user-input of the diamond plate area. This device will satisfy the key requirements to make this project successful. The device will measure capacitance during the polishing procedure and will be easy to move and use as needed in the lab.

Michigan State University

Team Members (left to right)

Ben Messiner

Royal Oak, Michigan

Jonathan Sparks

Jackson, Michigan

Cosmos Gyamfi

Manassas, Virginia

Surya Saravanakumar

Canton, Michigan

James Kervin

Bad Axe, Michigan

MSU Diamond Laboratory

Project Sponsor

Timothy Grotjohn

East Lansing, Michigan

Project Facilitator

Dr. Qi Hua Fan

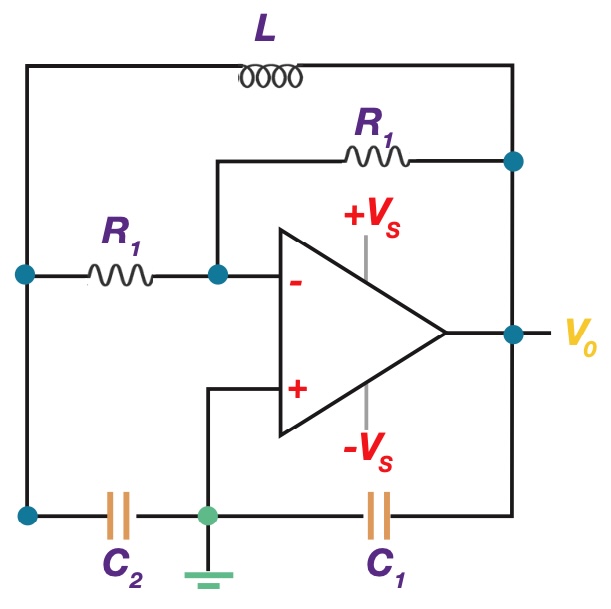

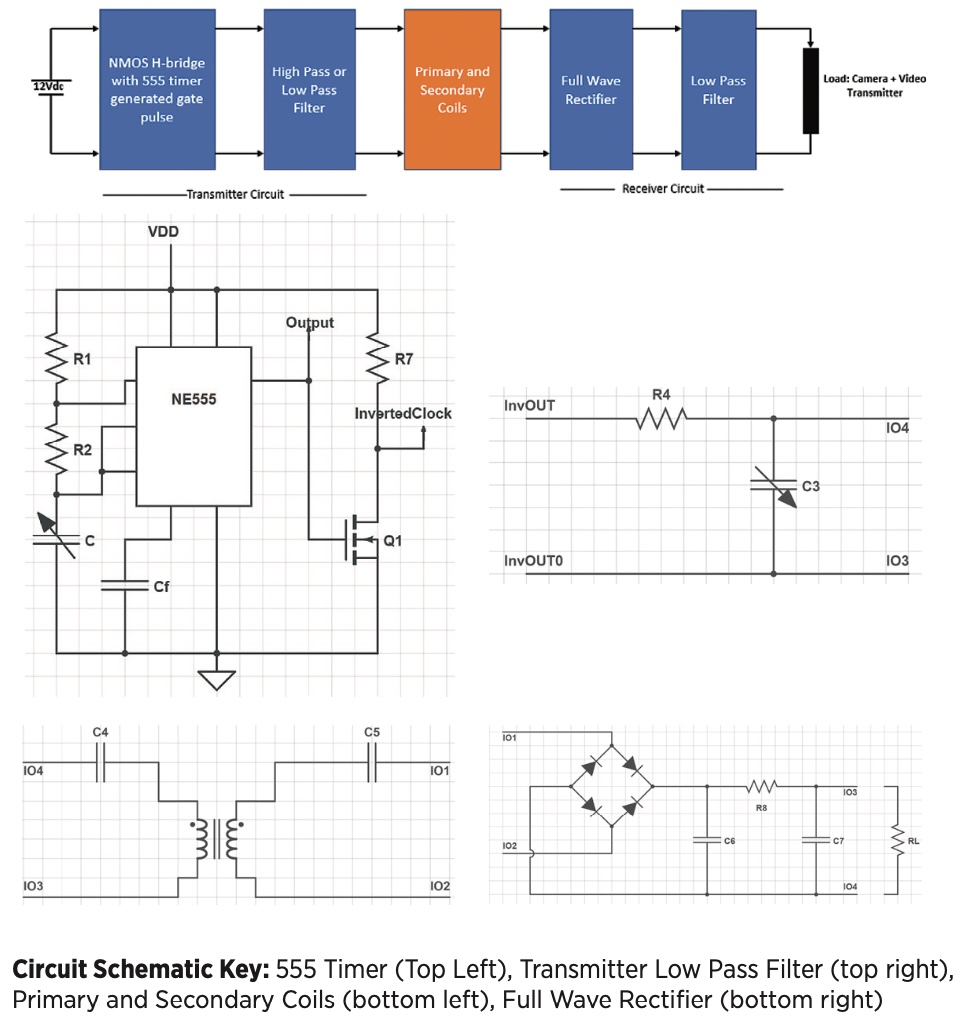

MSU Department of Electrical & Computer Engineering: Wirelessly Powered Backup Camera

Honda’s Ridgeline trucks have a known problem with the backup camera failing. The camera, which is located just above the handle for the tailgate is powered by the 12Vdc battery. The connection is made by old fashioned wire, which traverses across the hinge point of the tailgate.

For the past four years, Ridgeline trucks have been designed with a dual action tailgate. This tailgate opens in the normal manner and can also swing open sideways like a door. This extra movement causes additional stress on the cable that is responsible for delivering power to the camera and the video transmitter.

The goal of this project is to develop a wireless power transmission (WPT) system that is powered by 12Vdc and delivers 12Vdc to the load. A 12Vdc battery already exists within the Ridgeline truck which will serve as the main power source for the system. The load is made up of two components: a video camera and a video transmitter. The video camera requires 110mA and 12Vdc and the video transmitter requires 200mA at 12Vdc. This system will need to provide at least 350mA of current at 12Vdc without affecting any other electrical components in the truck.

Inductive coupling between a primary coil and a secondary coil is utilized to complete the wireless power transmission. The coils are placed in the gap between the tailgate and the truck’s taillight. Therefore, the system will only be operable when the tailgate is in the closed position.

Successful completion of this project will provide the Honda Ridgeline truck with an alternative way to deliver power to the backup camera without the need of physical wire connection. This system may even have the flexibility to be implemented into other truck models that are experiencing similar issues.

Michigan State University

Team Members (right to left)

John Slivka

Manistee, Michigan

John Paul Hanna

Farmington, Michigan

Fuad Sabit

Dhaka, Bangladesh

Prince Funwie

Farmington, Michigan

Francis Kasmikha

Farmington, Michigan

Michael Scruggs

Macomb, Michigan

MSU Department of Electrical & Computer Engineering

Project Sponsor

Tim Hogan

East Lansing, Michigan

Project Facilitator

Dr. Panagiotis Traganitis

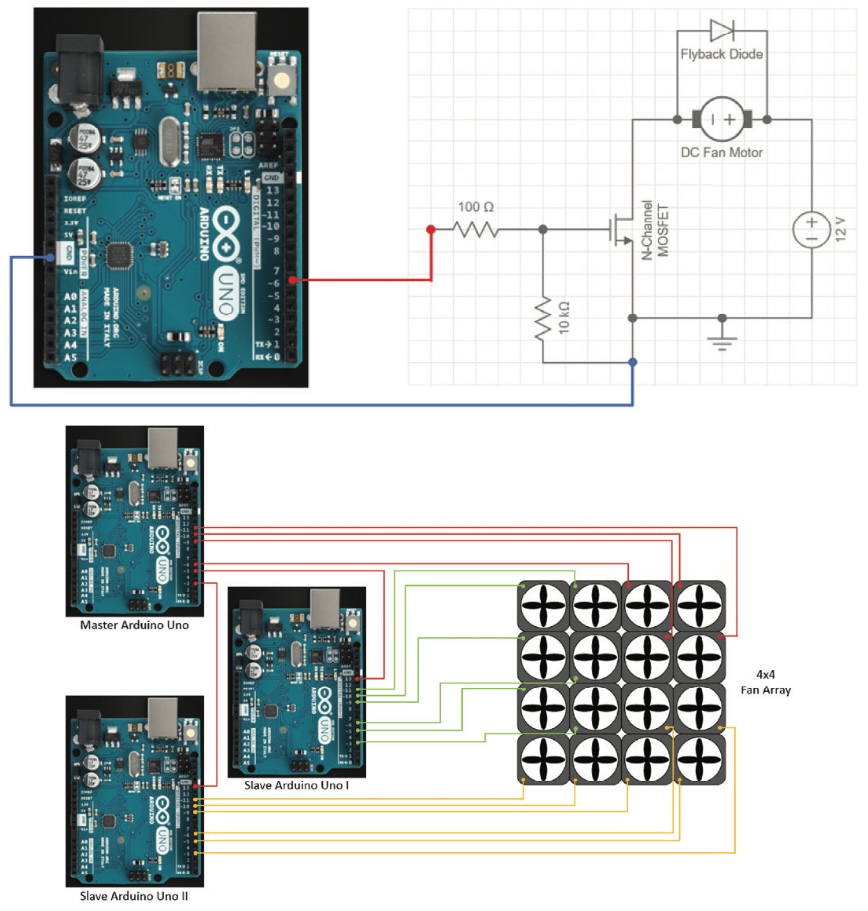

Michigan State Biomedical Engineering: Wind Tunnel for Molecular Communication

Molecular Communication is an emerging technology inspired by the molecular communication found within living organisms. This idea consists of conveying information via molecules within a controlled medium. It would potentially enable electrical devices to interface with biological cells for biomedical applications due to it being the natural way information is transported in the body on a microscale. This also would allow electrical devices to communicate with each other without the need for connecting wires, as the molecules will be able to travel through the air. One difficulty with this idea is the ability to control the direction and flow of molecules.

Our team’s goal is to design and construct a wind tunnel to allow control of the flow of molecules on the macroscale. This will be achieved by creating a 4×4 array of fans that will have three different intensity settings. By combining fans with different intensity settings, the direction airflow can be altered. This will be done using a set of Arduinos wired to the fans. Overall, the device we create will enable the user to alter the direction of airflow using a GUI that will interface with the Arduinos and change the fan’s intensities.

Michigan State University

Team Members (left to right)

Joe Kieta

Livona, Michigan

Brett Williams

Kawkawlin, Michigan

Mason Rice

Northville, Michigan

Garrett Vangilder

Davisburg, Michigan

Phong Hoang

Saline, Michigan

Alihelmael Avilés Sánchez

San Juan, Puerto Rico

Michigan State Biomedical Engineering

Project Sponsor

Bige Unluturk

East Lansing, Michigan

Project Facilitator

Dr. Robert McGough