The Chemical Engineering Capstone class participates in Spring Term Design Day. The following Design Problem was worked for Spring 2019

Manufacturing Facility for a Monoclonal Antibody

In 2019, the AIChE Student Design Competition problem was to design a biopharmaceutical plant to manufacture recombinant proteins used in a drug to treat advanced macular degeneration (AMD). The proteins are to be produced in Escherichia coli fermentations as intracellular “inclusion bodies”—protein aggregates about half a micron in size. After the fermentation, the E. coli cells are to be ruptured, and the inclusion bodies art to be recovered

by centrifugation. Finally, the inclusion bodies are to be transported to another facility, where they will be dissolved, and the protein components will be self-assembled into a monoclonal antibody that is biosimilar to the AMD drug Ranibizumab (trade name Lucentis). This antibody inhibits angiogenesis in the retina and thereby prevents the excessive blood-vessel growth that damages retinal function in AMD patients.

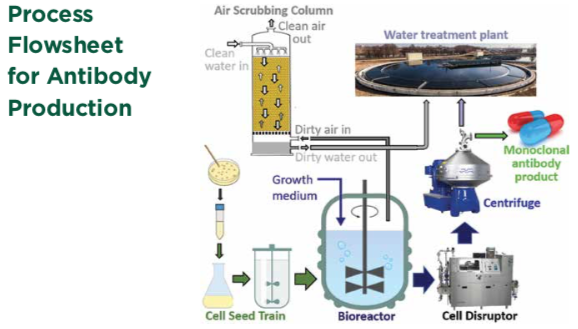

A simplified process flowsheet to produce the inclusion bodies is shown below. A seed train will be used to grow enough recombinant E. coli cell culture to inoculate the 6,000 L fermentor (about 5% by volume). To achieve a high final cell density and intracellular inclusion-body concentration, additional liquid growth medium is added, and air is sparged into the bioreactor. After the fermentation, the cells are mechanically ruptured to release the inclusion bodies, which are then recovered using a centrifuge and shipped. To protect the environment, an air-scrubbing column is used to remove H2S gas produced by the cells, and a wastewater-treatment process is used to remove cell debris and other contaminants.

AIChE Design Competition problems like this one require students to integrate a broad range of chemical engineering skills as they develop a process flowsheet; design and estimate costs of process equipment; incorporate strategies for heat and mass integration; follow environmental, health, and safety guidelines; develop mathematical models describing equipment performance; use process- simulation software (e.g., ASPEN) to predict the effect of key independent variables on overall plant performance, and then integrate economic models (e.g., discounted cash flow rate of return) with ASPEN simulations to analyze and optimize plant profitability.

AIChE problems provide only a modest amount of details, requiring students to apply strategies typical of real-world designs: conduct project-specific research, use experience- based engineering heuristics (i.e., rules of thumb), make reasonable engineering assumptions, and assess accuracy of the designs.