ChE Process Design and Optimization

Course Description

The Chemical Engineering Program’s capstone design sequence includes Process Design and Optimization I and

II (433 and 434, respectively). In these courses, students integrate content from earlier courses to solve complex, open-ended design problems. As the students progress through CHE 433, completion of their assignments requires increasingly more effort, initiative, knowledge, and individual responsibility. In CHE 434, students typically design an entire commercial-scale chemical plant and perform detailed economic analyses to assess and optimize the plant’s profitability.

For over 50 years, MSU’s CHE 434 students have worked intensively for one to two months solving the annual American Institute of Chemical Engineering (AIChE) Student Design Competition problem. CHE 434 uses these realistic, industry-based problems to enhance chemical engineering students’ capstone design experience for three reasons: 1) the AIChE problems provide real-world, open-ended design experiences typical of what students are likely to face after graduation; 2) the AIChE problems require students to do self-directed, active learning, including project-specific independent research, to solve the problem; and 3) the AIChE problems serve as a national benchmark for MSU’s Chemical Engineering students to demonstrate excellence in their professional skills.

As the Chemical Engineering program’s contribution to the College of Engineering’s Design Day, several CHE 434 students typically present posters describing their solutions to the current year’s AIChE Student Design Competition problem. Names and pictures of this year’s presenters are provided at the end of this article.

2024 Design Competition Problem: “Power to Gas”

The Power to Gas chemical process to be designed in this year’s AIChE Student Design Competition problem uses renewable energy to generate a sustainable fuel-gas supply while keeping greenhouse gas emissions in check. Some existing renewable power sources (e.g., solar and wind) have significant disadvantages. For example, the amount of electricity they produce is dependent on the availability of sunlight and wind, respectively, making it difficult to reliably match the power generation rate to the demand. Moreover, when the generation rate exceeds the demand, storage of the excess electricity in batteries is not cost-effective.

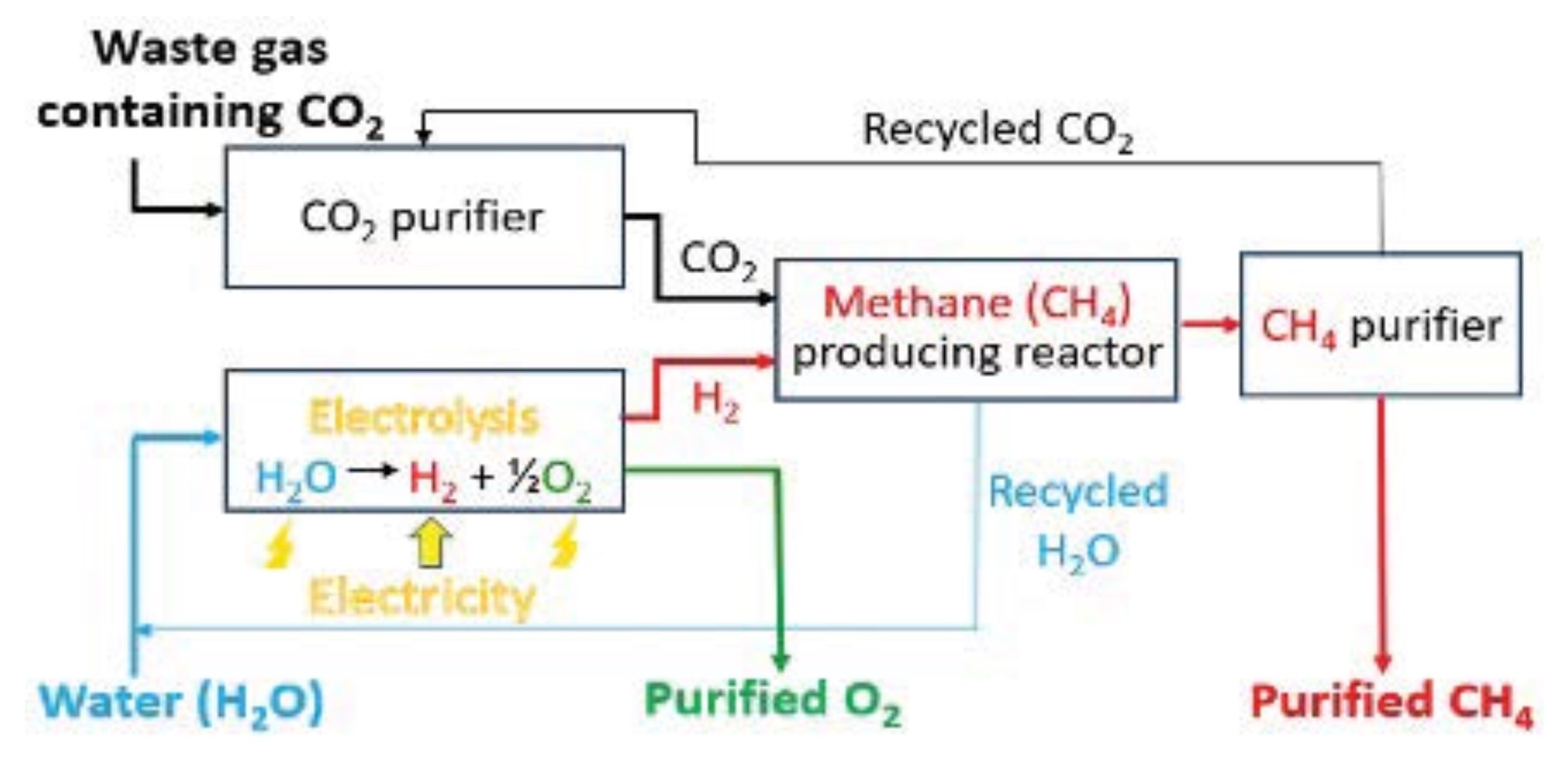

This year’s AIChE problem addresses this issue by using excess electrical energy to generate fuel gases, such as hydrogen (H2) and methane (CH4), which can be compressed and stored cost-effectively for use whenever needed. A simplified flow diagram for the Power to Gas process is shown in Fig. 1. Excess electricity would first be used to split water into H2 and O2 gases, and then the H2 would be reacted with the greenhouse gas carbon dioxide (CO2) to produce CH4. The CO2 consumed would be derived from a waste-gas stream that would otherwise be released into the atmosphere. That way, the Power to Gas process would be carbon neutral.

CHE 434 students use a multi-step process to design and optimize a chemical plant. In the first step, they perform hand calculations to estimate the performance and size of the major required pieces of industrial equipment (e.g., reactors, condensers, and distillation columns).

In the second step, they refine their estimates of equipment size and performance using a commercial computer-aided- design (CAD) program (e.g., ASPEN). The CAD programs are able to solve large systems of equations simultaneously. Finally, the students optimize the chemical plant’s profitability using detailed economic calculations that account for changes in the value of money over time (e.g., inflation). The resulting discounted cash flow rate of return value calculated for the optimized process would be used by a company to assess whether to make a large investment in the designed production plant.

After completing their designs, CHE 434 students prepare professional-quality written reports up to 50 pages long. These reports include details of the manufacturing plant’s equipment, operating conditions, personnel needs, capital investment, fixed costs, capital costs, and a detailed economic analysis. The reports are graded based on both their technical quality and their communication effectiveness. Because decisions on major capital investments (e.g., building a new production plant) are made by stakeholders having diverse academic backgrounds, the reports are expected to be understandable by a wide range of audiences.

Student Poster Presenters on Design Day

The nature of Chemical Engineering students’ capstone design experience does not lend itself well to small-scale, hands-on models for Design Day demonstrations. Chemical Engineering seniors’ Design Day contribution consists of presenting a lay- level poster of their design solution to the AIChE Design Competition problem and discussing with prospective students, current students, parents, and others the nature and advantages of careers in Chemical Engineering. This year’s poster presenters are listed and shown below. Individual presenters are Matt Skulski, Lauren Petrie, Kendra Fowler, Jenny Lane, Amjad Mashmoushi, and Bran Codlin (not shown). Two-person team presenters are Yanni Williams and Paige Pilarski, Zoe Linko and Megan Giltmier, Sean Reid and Mohamed Mohamed, and Justin Hamlin and Mason Razz.