ChE Process Design and Optimization

Course Description

The Chemical Engineering Program’s capstone design sequence includes Process Design and Optimization I and II (433 and 434, respectively). In these courses, students integrate content from earlier courses to complete complex, open-ended design assignments. As the students progress through CHE 433,

their assignments require increasingly more effort, initiative, knowledge and individual responsibility. In CHE 434, students typically design an entire commercial-scale chemical plant

and use detailed economic analyses to optimize the plant’s profitability.

For over 50 successive years, MSU’s CHE 434 students have worked intensively one to two months solving the annual American Institute of Chemical Engineering (AIChE) Student Design Competition problem. CHE 434 uses these realistic,

industry-based problems to enhance chemical engineering students’ capstone design experience for three reasons: 1)

the AIChE problems provide real-world, open-ended design experiences typical of what students are likely to face after graduation; 2) the AIChE problems require students to do self- directed, active learning, including project-specific research, to solve the problem; and 3) the AIChE problems serve as a national benchmark for MSU’s chemical engineering students to demonstrate excellence in their professional skills.

As the Chemical Engineering program’s contribution to Design Day, several CHE 434 students typically present posters describing their solutions to the current year’s AIChE Student Design Competition problem. Names and pictures of this year’s presenters are provided at the end of this article.

Closing Critical Gaps to Enable a Circular Economy of Plastics

This year’s AIChE Student Design Competition problem

is a complex, real-world one that requires collaboration of engineers, businesses, and governments: how to cost-effectively produce high-quality, new plastic products from recycled plastic products. The two-step chemical process involves (1) breaking down the polymers composing the recycled plastics into small molecular building blocks, and then (2) assembling the molecular building blocks into new, virgin plastics that can be shaped to form new commercial products.

This “Circular Economy of Plastics” approach has multiple dimensions of societal value. First, it addresses environmental problems associated with disposal of used plastic products. Second, it generates a diverse mix of valuable products, including new, virgin plastics and an array of oils that would otherwise have to be produced from petroleum.

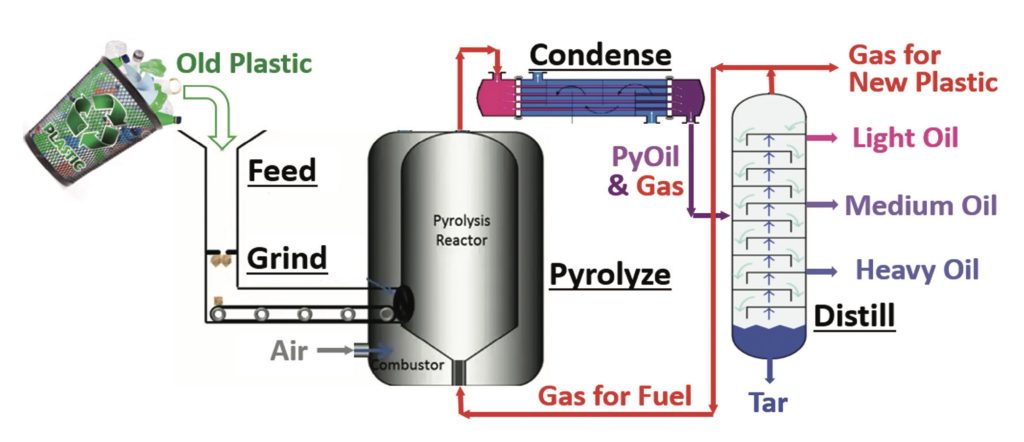

The process flowsheet for this year’s AIChE problem is shown in Figure 1. First, old plastic products are collected

and ground into small pieces. The ground plastics are fed to a pyrolysis reactor that heats them to a temperature that gasifies the plastics by breaking down the large polymer molecules that compose the plastic into a pyrolysis gas that contains a diverse mixture of smaller molecules. The pyrolysis gas is cooled in a condenser to form a pyrolysis oil (PyOil) and a reactive gas that can either be converted into new plastic products or burned as fuel to heat the pyrolysis reactor.

While the chemical reactions involved in this design challenge problem are not novel, the increased emphasis placed on producing new, virgin plastics from recycled plastics is. This problem also places an increased emphasis on having students integrate knowledge of a broad range of public health, safety, and welfare concerns, as they make informed judgments considering the impact of their engineering solutions in global, economic, environmental, and societal contexts.

CHE 434 students design a chemical plant able to meet the need specified by AIChE in a two-step process. In the first step, they perform hand calculations to estimate the performance and size of the major required pieces of industrial equipment (e.g., reactors, condensers, and distillation columns). In the second step, they refine their estimates of equipment size and performance using a commercial computer-aided-design (CAD) program (e.g., ASPEN) that is able to efficiently solve large systems of equations simultaneously.

Once students have developed a detailed CAD-based simulation of the production plant, they optimize the plant’s profitability using detailed economic calculations that account for changes in the value of money over time (inflation). The resulting discounted cashflow rate-of-return value calculated for the optimized process would be used by a company to assess whether to make a large investment in the designed production plant.

Process Flowsheet for 2022-2023 AIChE Student Design Competition Problem

After completing their designs, CHE 434 students submit professional-quality written reports up to 50 pages long. These reports include details of the manufacturing plant’s equipment, operating conditions, personnel needs, capital investment, fixed costs, capital costs, and a detailed economic analysis. The reports are graded based on both their technical quality and their communication effectiveness. Because decisions on major capital investments (e.g., building a new production plant) are made by stakeholders having diverse academic backgrounds, the reports are expected to be understandable by a wide range of audiences.

Student Poster Presenters on Design Day

The nature of Chemical Engineering students’ capstone design experience does not lend itself well to small-scale, hands-on models that are convenient for Design Day demonstrations. For that reason, Chemical Engineering seniors’ contribution

to Design Day consists of presenting a lay-level poster of their design solution to the AIChE Design Competition problem and discussing with prospective students, current students, parents, and others the nature and advantages of careers in Chemical Engineering.

Two-person Team Solution Poster Presenters at the AiChE Student Design Competition this year

Madison Melby and Harrison Ameel

James VanAntwerp

Ben Laubach

Camden Mills and Rana Elladki