The Chemical Engineering Capstone class participates in Spring Term Design Day. The following Design Problem was worked for Spring 2021.

Upgrading petroleum to higher value products

In 2021, the AIChE Student Design Competition problem related to a classic chemical-engineering challenge: how to upgrade petroleum to higher value chemical products. However, this project featured an international element, in that the plant should be designed for construction in a Middle-Eastern country. Thus, competitive design solutions had to incorporate global factors.

Students were assigned to design a plant that integrated chemical reactions and multistep separations processes to a petroleum fraction (naptha) into the value-added chemicals benzene, toluene and xylene (BTX), as well as transportation fuel (gasoline and diesel).

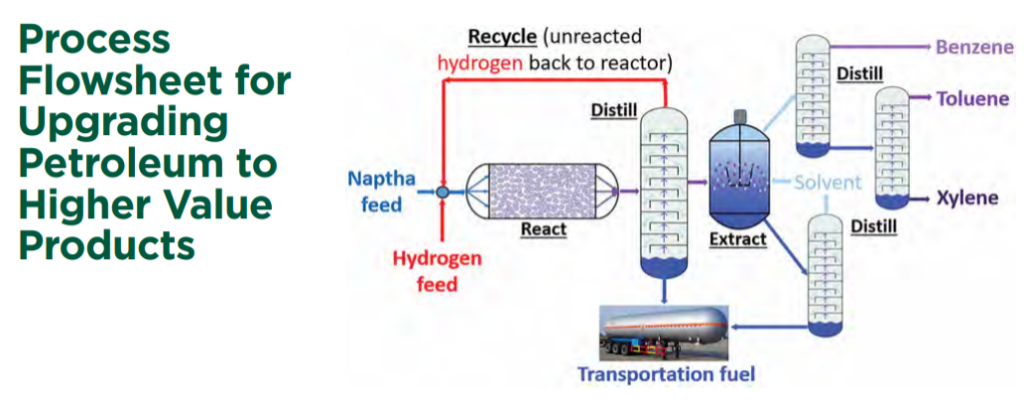

Students are allowed considerable flexibility in how the chemical plant would be laid out in these open-ended capstone design assignments. One example of a (greatly simplified) process flow sheet is shown below. The naptha and hydrogen gas would be delivered to a reactor vessel, where the naptha is converted in to a mixture of products. A distillation column is used to separate the products emerging from the reactor into three streams: (1) unreacted hydrogen gas, which is recycled to the reactor, (2) a mixture of compounds that are well suited as transportation fuel, and (3) a mixture of chemicals rich in the desired BTX products. A solvent-extraction process is then used to remove additional transportation fuel, and then three distillation columns are used separate the BTX mixture into three the final products. One column is used to recover the solvent, which is reused, the second is used to purify the benzene, and the third is used to separate the toluene from the xylene.

An important requirement of the project is a detailed economic analysis that predicts the profitability of the chemical plant. To account for changes in the value of money over time, a discounted cashflow rate of return on the company’s investment is determined. By integrating this economic analysis with a comprehensive, predictive mathematical model of the chemical plant, students can optimize their designs by determining the values of key design parameters that maximize the profit.

However, the economic optimization must be done within the constraints of multiple other factors, most notably safety and environmental compliance. Each report is required to include detailed analyses of safety and environmental risks and strategies implemented to mitigate those risks.

Each final report is required to specify details required to build and operate the plant the student designed, including the specifications for the plant’s equipment, operating conditions, personnel needs, capital investment, working capital, utilities needed, etc. While these reports have historically been allowed to be up to 225 pages long, this year, for the first time, AIChE imposed a length limit of 50 pages. This new constraint required ChE 434 students to not only be strong technically but also be able to write a report that is well-organized, clear, and concise.

For Design Day, several ChE 434 students present posters on their solutions to the AIChE Design Competition problem. Due to COVID-19 restrictions, this year the poster presentations will be given virtually, rather than in-person. The students who will present team-solution posters are shown below.