We gratefully acknowledge Jim Manely and the Demmer Center for Business Transformation at Michigan State University for their guidance and assistance with our projects. We gratefully acknowledge Judy S. Jacobs, Director, Corporate & Student Relations Office, Michigan State University, Department of Supply Chain Management for her assistance in securing projects.

For information on becoming a project sponsor, please contact Dr. Laura Genik.

The Applied Engineering Sciences Capstone class is held in Spring Term only. The following were the project sponsors and projects for the Spring of 2015:

Bulk Truck Capacity Utilization Analysis

Currently Asahi transports 30% of their finished products using bulk trucks. A typical bulk truck can hold up to 48,000 lbs of material. They have a fleet of around 35 bulk trucks at their disposal. Each truck is dedicated to a family of products. With an increase in volumes over the past four years, there has been a constraint on the availability of the bulk trucks. This project did:

Currently Asahi transports 30% of their finished products using bulk trucks. A typical bulk truck can hold up to 48,000 lbs of material. They have a fleet of around 35 bulk trucks at their disposal. Each truck is dedicated to a family of products. With an increase in volumes over the past four years, there has been a constraint on the availability of the bulk trucks. This project did:

- Map the current bulk truck usage,

- Evaluate alternative options that are available in the marketplace,

- Optimize the scheduling of the bulk trucks, taking into consideration the customer demand, driver hours, transit time and other variables, and

- Propose capital investments (if necessary) to increase fleet utilization and increase customer satisfaction

Master Logistics Plan – Wyandotte, Michigan

The goal of this project is to create a new master logistics plan for the BASF Wyandotte site. The BASF Wyandotte site is one of the largest BASF sites in North America with 1,200+ employees in manufacturing, administration and Research and Development. The site has approximately 40,000 inbound shipments and 26,000 outbound shipments per year, in addition to having inbound and outbound rail shipping.

The goal of this project is to create a new master logistics plan for the BASF Wyandotte site. The BASF Wyandotte site is one of the largest BASF sites in North America with 1,200+ employees in manufacturing, administration and Research and Development. The site has approximately 40,000 inbound shipments and 26,000 outbound shipments per year, in addition to having inbound and outbound rail shipping.

The new master logistics plan will include a new truck check-in area, new security center building, new small package receipt and mailroom, new truck driver and contractor orientation center, new truck inspection rack, parking lots and existing assets on the site.

Cost Model for Utilizing Recycled Carbon Fiber in a Paper-making Process

The purpose of this project is to look at the economic value of recycled carbon fiber with uniformly dispersed matrix which has been made into random mats using wet lay, day lay or paper/mat making processes.

The purpose of this project is to look at the economic value of recycled carbon fiber with uniformly dispersed matrix which has been made into random mats using wet lay, day lay or paper/mat making processes.

Production of carbon fiber is forecasted to increase in the coming years with its applications continuing to grow in aerospace and automotive industries. With the increase in usage, the quantity of scrap carbon fiber from manufacturing and end-of-life will also increase in the coming years.

Several solutions are available to recover carbon fiber from its various forms uncured prepregs and tapes, fabrics, dry fiber to cured laminates. These solutions include pyrolysis which involves recovering the fiber through elevated temperature and in the absence of oxygen. An alternative is solvolysis which relies on chemicals at high temperature and high pressures to recover the fiber and resin.

The recovered fiber from these processes, combined with thermoplastic matrix filaments, can be used in applications such as dry lay carding and papermaking processes to make random mats which can be molded into composite parts. This team will focus on taking recycled fiber from various sources and modeling the cost of processing the fiber through these processes. The results, coupled with engineering design data, can be used to compare the mats with other materials to determine the economic position in the market.

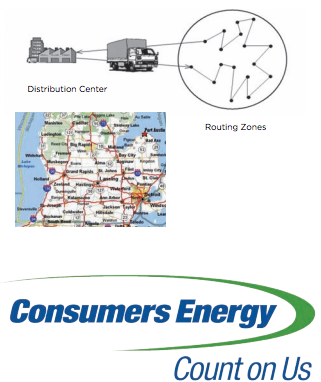

Optimizing Logistics Transportation Routing and Scheduling

Consumers Energy’s internal logistics system includes transportation routes across the State of Michigan to/from approximately 40 company sites. Routes and schedules should be evaluated to determine the most efficient and cost-effective method. This project should result in cost savings in terms of fuel, mileage, and time savings without impacting service levels. The goal is to review the entire logistics transportation network to find areas of improvement, including efficiency, reduction in waste, and optimization of services offered. In addition, the project team should review two other scenarios for cost savings opportunities resulting from the consolidation of (3) material distribution warehouses into (2) locations, as well as potential consolidation into a single distribution center.

Consumers Energy’s internal logistics system includes transportation routes across the State of Michigan to/from approximately 40 company sites. Routes and schedules should be evaluated to determine the most efficient and cost-effective method. This project should result in cost savings in terms of fuel, mileage, and time savings without impacting service levels. The goal is to review the entire logistics transportation network to find areas of improvement, including efficiency, reduction in waste, and optimization of services offered. In addition, the project team should review two other scenarios for cost savings opportunities resulting from the consolidation of (3) material distribution warehouses into (2) locations, as well as potential consolidation into a single distribution center.

Benchmarking and Market Assessment for Rear View and SurroundView Camera Systems

The impact of this project will be to increase and accelerate market knowledge for the Rear View and SurroundView Camera Systems that Continental Automotive Systems ADAS BU is developing, and by doing so, help position Continental to become a leader in supplying such systems to the NAFTA market. We hope to better understand both our competition and our customers at the end of the project. In phase 1, the team will identify key design criteria existent in the current market for both Rear View and SurroundView Camera Systems for automotive applications. In phase 2, the team should identify alternatives for product positioning for all rear and “360-degree” / SurroundView Systems. The desired result from this phase is to prioritize a development path that fits these parties. Any system architecture direction, preferences for security / safety / comfort / convenience features, and preferred new features or functions that are wanted / needed should be captured / defined.

The impact of this project will be to increase and accelerate market knowledge for the Rear View and SurroundView Camera Systems that Continental Automotive Systems ADAS BU is developing, and by doing so, help position Continental to become a leader in supplying such systems to the NAFTA market. We hope to better understand both our competition and our customers at the end of the project. In phase 1, the team will identify key design criteria existent in the current market for both Rear View and SurroundView Camera Systems for automotive applications. In phase 2, the team should identify alternatives for product positioning for all rear and “360-degree” / SurroundView Systems. The desired result from this phase is to prioritize a development path that fits these parties. Any system architecture direction, preferences for security / safety / comfort / convenience features, and preferred new features or functions that are wanted / needed should be captured / defined.

Planning Part Complexity Management in Automotive Manufacturing

Ford Motor Company is a world-class automobile manufacturing company, producing a wide range of vehicles across an extensive worldwide distribution network. Our vehicles are manufactured regionally and globally for regional sales as well as for export.

Ford Motor Company is a world-class automobile manufacturing company, producing a wide range of vehicles across an extensive worldwide distribution network. Our vehicles are manufactured regionally and globally for regional sales as well as for export.

Regional requirements (legal / manufacturing) and customer preference can drive a significant amount of complexity into component design. Exterior mirrors, for example, may feature anywhere from 40 to well over 100 different buildable combinations for one vehicle.

Where this level of complexity occurs, different manufacturing and logistics solutions are devised to handle the complexity. In-Line Vehicle Sequencing (ILVS), Batch Building, Band use of Broadcast Build systems are methodologies used within Ford and our suppliers’ plants to manage complexity.

This project seeks to create a tool that can be used to assess and define the optimal way to manage part or component complexity costs into Ford facilities from our production part supplier facilities. The goal for this tool is to identify cost savings and avoidances both in reduced component piece cost and reduced manufacturing costs at Ford adding to the bottom line.

Distribution Model for Raw Materials in the Aerospace Electronics Manufacturing Industry

Each of the seven GE Aviation electronic manufacturing sites currently has its own supply chain fulfillment model in place. GE Aviation desires to develop a standard solution for raw material fulfillment into each of these manufacturing sites. Potential solutions to this challenge could include but are not limited to: developing a distribution center model, utilizing a 3rd party logistics provider, implementing a vendor manage inventory system, or centralizing the Sourcing function. GE Aviation would like this project to include a benchmarking exercise of the best in class organizations in electronics fulfillment. The new model must allow GE Aviation to reduce overhead costs at each site, leverage increased spend volume, improve inventory turns, and allow for a higher on-time delivery performance to each of the GE Aviation sites.

Each of the seven GE Aviation electronic manufacturing sites currently has its own supply chain fulfillment model in place. GE Aviation desires to develop a standard solution for raw material fulfillment into each of these manufacturing sites. Potential solutions to this challenge could include but are not limited to: developing a distribution center model, utilizing a 3rd party logistics provider, implementing a vendor manage inventory system, or centralizing the Sourcing function. GE Aviation would like this project to include a benchmarking exercise of the best in class organizations in electronics fulfillment. The new model must allow GE Aviation to reduce overhead costs at each site, leverage increased spend volume, improve inventory turns, and allow for a higher on-time delivery performance to each of the GE Aviation sites.

Customer Service Process for Recycling and Surplus Department

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

This project team will work directly with MSU Sustainability’s recycling and surplus department with regard to customer service. The department has begun to develop a customer service program, responding to the university’s directive to provide exceptional customer service to all customers. The project will work to create a system that not only tracks customer service but also works on methods to report those results to internal and external audiences, interprets findings, and works for continuous improvement.

This project team will work directly with MSU Sustainability’s recycling and surplus department with regard to customer service. The department has begun to develop a customer service program, responding to the university’s directive to provide exceptional customer service to all customers. The project will work to create a system that not only tracks customer service but also works on methods to report those results to internal and external audiences, interprets findings, and works for continuous improvement.

Spartan Treasure Hunt – Finding Energy Efficiency through Occupant Engagement

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

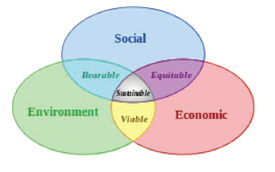

The Spartan Treasure Hunt (STH) project is to create a process to measure the ROI of our Spartan Treasure Hunt program which is focused on energy efficiency and occupant engagement. The project team will learn about the project, understand the intended outcomes and work to develop a process by which MSU can measure the economic, energy, and social impacts. This project will work to answer the questions: “Is the investment in the project worth the outcome? Is the expense of both time and money generating valuable results?”

The Spartan Treasure Hunt (STH) project is to create a process to measure the ROI of our Spartan Treasure Hunt program which is focused on energy efficiency and occupant engagement. The project team will learn about the project, understand the intended outcomes and work to develop a process by which MSU can measure the economic, energy, and social impacts. This project will work to answer the questions: “Is the investment in the project worth the outcome? Is the expense of both time and money generating valuable results?”

Spartan Treasure Hunt – Finding Energy Efficiency through Occupant Engagement

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

The goal of this project is to analyze plug load for campus office spaces and construct an ideal workspace that can provide the maximum amount of energy and cost savings. The result of the project should be a recommendation on how to implement and equip energy efficient office space.

The goal of this project is to analyze plug load for campus office spaces and construct an ideal workspace that can provide the maximum amount of energy and cost savings. The result of the project should be a recommendation on how to implement and equip energy efficient office space.

Customer Service Continuous Improvement for Recycling and Surplus Department

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

This project team will work directly with MSU Sustainability’s recycling and surplus department with regard to customer service. The department has begun to develop a customer service program, responding to the university’s directive to provide exceptional customer service to all customers. The project will work to create a continuous improvement process on customer service.

This project team will work directly with MSU Sustainability’s recycling and surplus department with regard to customer service. The department has begun to develop a customer service program, responding to the university’s directive to provide exceptional customer service to all customers. The project will work to create a continuous improvement process on customer service.

Optimization of Water Usage on Campus through Data Collection and Analysis

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

The project focuses on research into data collection and reporting methods of water usage on campus, as well as developing a process by which to collect and share that water usage and quality data. Deliverables include recommendation of key metrics that we should use to analyze the water system.

The project focuses on research into data collection and reporting methods of water usage on campus, as well as developing a process by which to collect and share that water usage and quality data. Deliverables include recommendation of key metrics that we should use to analyze the water system.

Spartan Treasure Hunt – Finding Energy Efficiency through Occupant Engagement

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

MSU Sustainability values student interaction, creating a positive student experience, offering opportunities for students to gain real-world experience and access to professional staff, creating a connection to academic departments, and approaching projects from a student-focused perspective.

The Spartan Treasure Hunt (STH) is to create a process to measure the ROI of our Spartan Treasure Hunt program which is focused on energy efficiency and occupant engagement. The project team will learn about the project, understand the intended outcomes and work to develop a process by which MSU can measure the economic, energy, and social impacts. This project will work to answer the questions: “Is the investment in the project worth the outcome? Is the expense of both time and money generating valuable results?”

The Spartan Treasure Hunt (STH) is to create a process to measure the ROI of our Spartan Treasure Hunt program which is focused on energy efficiency and occupant engagement. The project team will learn about the project, understand the intended outcomes and work to develop a process by which MSU can measure the economic, energy, and social impacts. This project will work to answer the questions: “Is the investment in the project worth the outcome? Is the expense of both time and money generating valuable results?”