Applied Materials: Commodity Hedging Program

Asahi Kasei Plastics North America: Line Capacity & Rebalancing Dashboard

BASF: Herbicide Data Vizualization and Forecasting

bp: Identify Best Approach to Buying Emerging Technology

bp: Identify Top Suppliers’ Carbon Emission Data

Bell Flight: Supplier Risk Analysis and Prediction Model

Caterpillar: End-to-End Kit Process Optimization

Caterpillar: Kit Assembly Automation

Caterpillar: Small Part Distribution Optimization

Clarience Technologies: Strategic Sourcing

Dow Inc: Replicating Supply Chain Inventories and Policies

General Motors: Supplier Risk Assessment and Key Risk Indicators

Genpact: Improving Supply Chain Processes

Guardian Glass: Stock Level Optimization Tool

Intel: Common Items Bulk Buy Strategy

Intel: Consolidated Shipping Project

RPM Freight Systems: Reducing the Carbon Footprint

RPM Freight Systems: Capacity Aggregation

RPM Freight Systems: Streamlining the Home Delivery & Pick-Up Processes

RENK: Best-in-Class Key Performance Indicators

RENK: Purchase Order Compliance Package Process

Rockwell Automation: Warehouse Manufacturing and Bin Optimization

SNACKWERKS: Single Station Automation Project

Tenneco: Cost Modeling and Verification in the Global Automotive Aftermarket

Applied Materials: Commodity Hedging Program

Applied Materials is a corporation that specializes in supplying manufacturing equipment for semiconductor companies. The commodity hedging program for Applied Materials focused on developing a tool that can protect the company’s margins and provide suggestions on pricing strategy based on timing and external factors that affect cost. By using research on best-known methods (BKM) for sourcing various raw materials as well as pricing trends, the team condensed the data to create a tool to predict pricing trends in Microsoft Excel and Tableau.

The project was based on developing a management approach of raw materials that consisted of aluminum, copper, and hot rolled steel/cold rolled steel. By looking at pricing trends and connecting them with relevant events (geo-political, fiscal, and more), direct links were drawn and used to draw conclusions on the reasoning behind why prices fluctuate. With the help of regression analysis, the team linked certain causal evidence for pricing which would later be useful for predicting best times to secure base prices on materials. The team researched BKMs that automotive and aerospace companies use for procurement of raw materials and used this information to provide suggestions to Applied Materials. This research was the foundation for a compilation of the findings to create a price prediction tool for Applied Materials’ sourced raw materials. By using research from past years’ pricing, the tool will give rough estimates for future pricing and aid the procurement team in purchasing decisions moving forward.

Ultimately, this project will help Applied Materials with their decision-making regarding sourcing strategy. This way, the company will be able to secure base prices at times in the year that are optimized by solidifying purchase dates and prices for the year. These saved resources can be reinvested into improving other aspects of the supply chain for both short and long-term benefits.

Michigan State University

Team Members (left to right)

Mackenzie Haw

Davison, Michigan

Jacqueline Fayad

Troy, Michigan

Bruce Chen

Shaanxi, China

Sydney Lintol

Clarkston, Michigan

Shuting Zhao

Shenzhen, China

Applied Materials

Project Sponsors

Scott Cornelius

Santa Clara, California

Jacob Klenda

Santa Clara, California

Brad Olson

Santa Clara, California

Teaching Assistant

Ishaan Anand

Asahi Kasei Plastics North America: Line Capacity & Rebalancing Dashboard

Asahi Kasei Plastics North America is a leading manufacturer of innovative, high performance, engineered polymers and advanced polypropylene compounds. These high-performance plastic compounds can be found in most segments of life. With roots in the automotive industry, on average about 11 pounds of plastics on cars today are sourced from Asahi Kasei Plastics. It can also be found in various other segments: pool and spa, industrial, furniture, housing, construction and many more.

Asahi Kasei Plastics has partnered with Michigan State University on a line capacity and rebalancing dashboard. Asahi Kasei has ten manufacturing lines at their Fowlerville, Michigan plant and three at their Athens, Alabama plant, all producing plastic compounds. Different materials are produced on different lines, and some materials can be produced on multiple lines. The planning team for Asahi Kasei Plastics takes monthly forecasts, purchase orders, and historical data to assign how much material needs to be produced on each line. The current COVID-19 pandemic has resulted in raw material shortages and high fluctuations in demand, which is causing frequent changeovers and unplanned downtime in the plants. As a result, Asahi Kasei is often in shortage of supply or has excess inventory.

To solve these issues, we created a dashboard that visually displays a 12-month window of supply and demand for each plant that can filter down by line, plant, month, and week. This will allow Asahi Kasei to prepare for any “what if…” scenarios and create efficiency goals per line. Our team investigated variables such as max line capacity, sales orders, and line utilization to help us throughout this semester. This dashboard was created with a stagnant data set but will be used as a template for Asahi Kasei’s planning team to connect to SAP and serve as a live dashboard following completion of our project.

Michigan State University

Team Members (left to right)

Brendan Bergeron

Grosse Pointe, Michigan

Sachi Arora

Novi, Michigan

Parker Rieth

Grosse Pointe, Michigan

Tarek Elkabbani

Hillsborough, New Jersey

Xuanyu Ji

Lianyungang, Jiangsu, China

Asahi Kasei Plastics

Project Sponsors

Jeff Bishop

Fowlerville, Michigan

Brian Broglin

Fowlerville, Michigan

Aaron Dunn

Fowlerville, Michigan

Teaching Assistant

Akash Mehrotra

BASF: Herbicide Data Vizualization and Forecasting

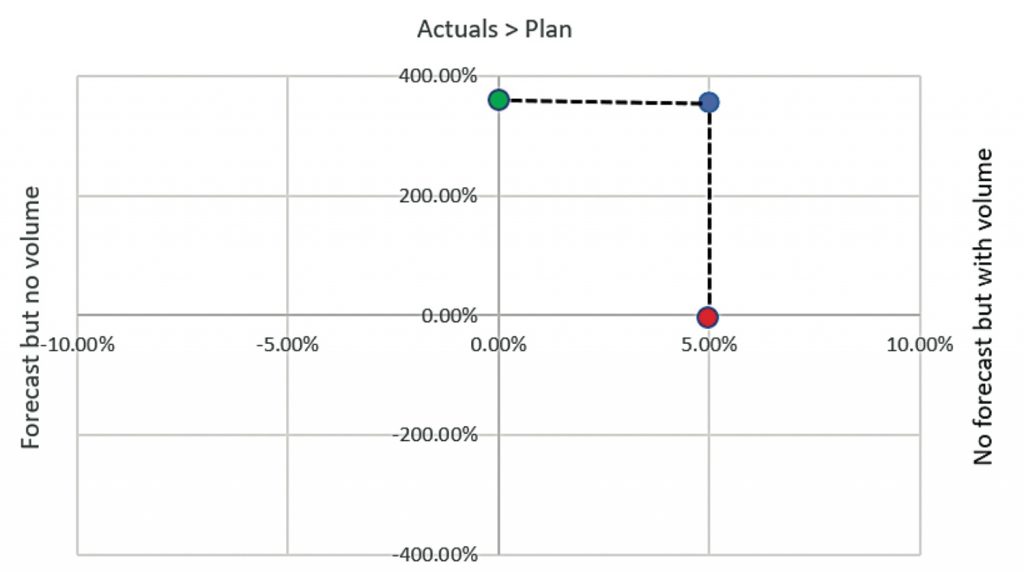

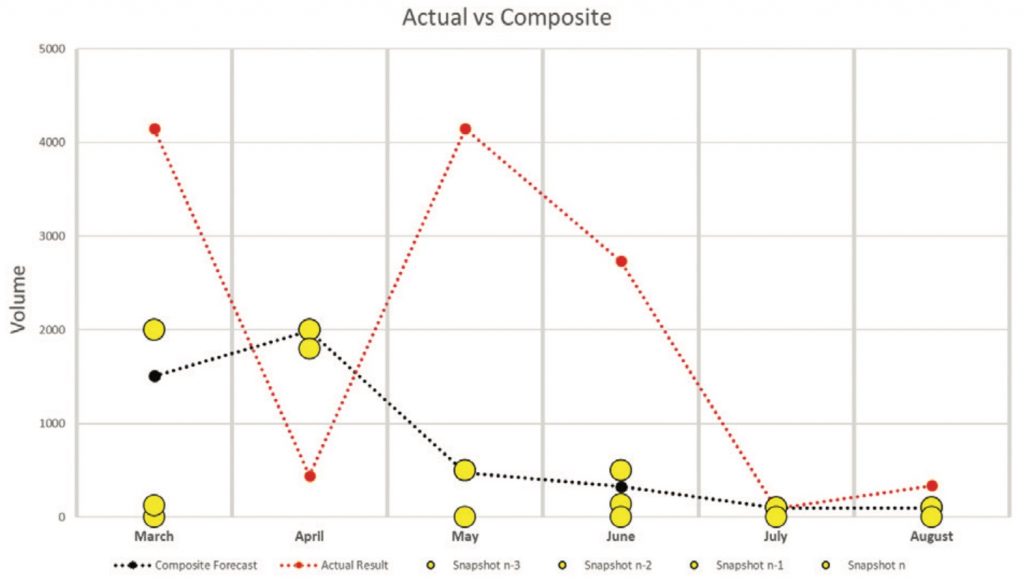

BASF is a multinational chemical company headquartered in Florham Park, New Jersey focused on innovating chemistry for the future. Because of their wide array of products, BASF is in many different industries spanning from agriculture and health to consumer goods and transportation. By combining economic success with environmental protection and social responsibility, BASF’s agrichemical business has made a name in the world’s top 10. BASF has been providing the agriculture industry with weed control solutions to help not only with yields and quality, but also resistance management. In this strong market, BASF is seeking a fresh perspective on current herbicide forecasting techniques and how to gain an orderly and concise plan for future sales.

Our team was tasked with evaluating forecasting behaviors through data processing and visualization techniques to support BASF’s journey to build improved forecast management. The outputs will be used to discover forecast tendencies, such as over or under forecasts and the extent of discrepancy. We worked to develop user-friendly data visualizations tools that can summarize and consolidate findings at SKU and category level in different time frames (month, season, year). Through a coupling of data-driven insights made accessible through data visualization, MSU and BASF teams will successfully see the effectiveness and weaknesses of the current forecasting methods, the first step into the development of new and improved forecasting techniques.

Michigan State University

Team Members (left to right)

Jessica Laze

Troy, Michigan

Emme Darkowski

Brighton, Michigan

Brennan Parks

Troy, Michigan

Sammy Powers

Commerce, Michigan

Jessica Mo

Johnson City, Tennessee

BASF

Project Sponsors

Matthew Bloom

Portland, Oregon

Greg Dibble

Durham, North Carolina

Teaching Assistant

Ishaan Anand

bp: Identify Best Approach to Buying Emerging Technology

bp, a multinational company, is headquartered in London, England. bp has been one of the world’s largest oil and gas companies since 1910. Now also regarded as an energy company, bp recognizes the impact emerging technology can have on operations and sustainability.

bp defines a robot as a machine capable of carrying out a complex series of actions automatically. The increasing use of robotics has opportunities to improve safety, increase efficiency, and drive sustainability. bp currently utilizes machine hardware, robots that perform work independently, and service robots, robots that perform a service via drone or in person. A majority of the robots currently used in bp include quadrupeds, telecommunication robots, cleaning robots, and marine robots. Demand and deployment of robotics at bp are both fragmented and decentralized; there is currently no standard way of buying and leasing robots internally.

Our team is conducting a fiscal analysis comparing buying, leasing, and contracting these robots to give bp a recommendation for bp’s future state. The team is also presenting a Porter’s Five Forces analysis of the market landscape characteristics and key suppliers of the robotics market. A more informed analysis of the suppliers in the global market of robotics will be used to help bp source strategically and therefore improve their competitive positioning in the energy industry.

With the robotics industry evolving rapidly, bp is looking to explore new opportunities by partnering with companies that provide innovative opportunities to maintain a competitive advantage. Our team is researching and presenting interesting ventures that will become influential in the upcoming years of robotics and will help improve bp’s overall strategic positioning in their industry. Additionally, we are conducting a SWOT analysis to determine the benefits and risks of engaging in new enterprises.

Michigan State University

Team Members (left to right)

Yucen Chen

Taicang, China

Gillian Tibbetts

Ann Arbor, Michigan

Ryan Spencer

Detroit, Michigan

Larissa Diarra

Ann Arbor, Michigan

Sana Ansari

Canton, Michigan

bp

Project Sponsors

Umama Qureishy

Houston, Texas

Nikita Sejpal

Ashford, United Kingdom

Teaching Assistant

Jose Naime

bp: Identify Top Suppliers’ Carbon Emission Data

bp is a multinational oil company that is headquartered in London, England. Since 1908, when oil was discovered in Persia, bp has been one of the world leaders in the global energy industry. bp continued to grow over the next century while more oil was found worldwide, and they have now massed a workforce of over 14,000 employees. Along with their company growth, their supply chain has rapidly developed to over 46,000 suppliers over 60 different countries. This causes bp to have a large global footprint at a scope 3 level, and therefore they have developed a net zero carbon emissions goal by 2050.

In pursuit of this goal, our team worked with bp’s Digital and Talent Procurement team to identify top suppliers and their alignment with the net zero ambition. After identifying a comprehensive list of suppliers in collaboration with category leads within bp, the MSU team honed in on fifteen suppliers to begin data collection over a two-week sprint. Through research into each supplier’s published sustainability report and collaborative discussions with each supplier, we compiled carbon emission data used to establish a carbon baseline, breakout data by Scope 1, 2, and 3, and identify emissions specifically attributed to bp. This baseline will be used to track each supplier’s progress with reducing carbon emissions. In addition, the team looked into how frequently suppliers measured and reported these metrics.

Our team also collected information regarding the largest sources of carbon emissions within the suppliers’ supply chains, current initiatives to reduce their global footprint, and milestones along the way to reaching their carbon reduction goals. These metrics provided bp with clarity on how they align with their supply base on aspirations to become environmentally sustainable and identified areas that needed more focus. The data collected by our team will be used to create a central dashboard within bp to assess the overall carbon impact of the company on an ongoing basis.

Michigan State University

Team Members (left to right)

Ishani Misra

Northville, Michigan

Nicole Dastmalchi

Novi, Michigan

Christopher Jakiel

Caledonia, Michigan

Brett Lanski

Romeo, Michigan

Nick Tullemans

Eden Prairie, Minnesota

bp

Project Sponsors

Bryan Adcock

Houston, Texas

Nikita Sejpal

Ashford, United Kingdom

Kathleen Silverman

Houston, Texas

Teaching Assistant

Ishaan Anand

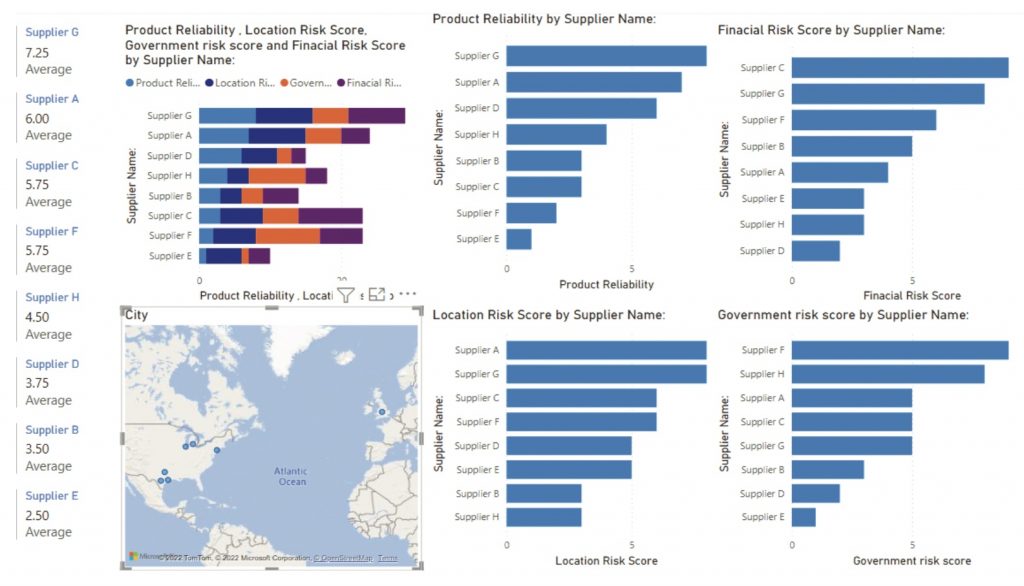

Bell Flight: Supplier Risk Analysis and Prediction Model

The Covid-19 pandemic created unprecedented logistic issues, especially regarding supply chain security and supplier reliability. Prior to the pandemic, Bell Flight did not have a system in place to analyze individual supplier information and predict the overall security of suppliers. This issue resulted in the loss of several of Bell Flight’s suppliers. To prevent an event like this in the future, Bell Flight has partnered with our team to develop a comprehensive risk analysis and management model.

The model will allow Bell Flight to see the comprehensive risk status of their suppliers. This tool will be used to analyze potential risk factors pertaining to suppliers, provide an overall risk score for each supplier and prescribe actions to mitigate negative impacts to the company’s supply chain. Data for individual suppliers is broken down into a collection of categories. Coefficients associated with risk factors are then assigned to each category using the data envelopment analysis method. The coefficient values are used to calculate the risk score for a particular metric and combined in the overall risk score of a supplier. The processed data will be displayed through a dashboard, providing Bell Flight with a high-level overview of the company’s suppliers, along with the capability to pinpoint specific risk factors that are contributing the most to a supplier’s overall risk score.

Bell Flight does not have a system to analyze the risk of their suppliers. The tool developed by our team focuses on calculating the overall risk of individual suppliers by utilizing multiple individual risk factors that are identified as potential threats to Bell Flight. The benefits include the early identification of high-risk suppliers along with mitigation strategies. This allows Bell Flight to act preemptively by either locating a new supplier or working with the current supplier to mitigate risk and improve reliability.

Michigan State University

Team Members (left to right)

Brendan Driscoll

Whitmore Lake, Michigan

Jason Spilko

Macomb, Michigan

Hunter Smith

Rochester Hills, Michigan

Tommy Pritchett

Midland, Michigan

Bell Flight

Project Sponsors

Danny Spivey

Fort Worth, Texas

Matt Sticksel

Fort Worth, Texas

Scott Willie

Fort Worth, Texas

Teaching Assistant

Sneha Abhyankar

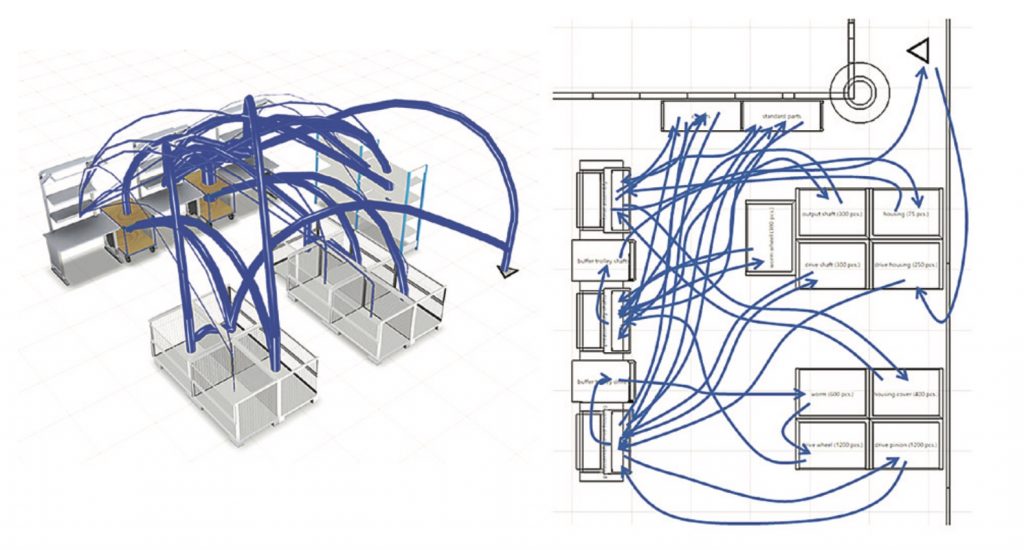

Caterpillar: End-to-End Kit Process Optimization

Caterpillar is a leading manufacturer of construction and mining equipment, highway diesel and natural gas engines, industrial gas turbines, and diesel-electric locomotives. To provide additional value to customers, Caterpillar assembles aftermarket service kits for their products. This allows the customer to purchase an entire kit for their service needs rather than tediously buy all the necessary parts individually.

Caterpillar is partnered with Michigan State University to improve the assembly process of such kits within Caterpillar’s Midwest Logistics Center, located in Champaign, Illinois. Further, it is hoped that investigation into the kitting process will help to reduce downtime and the reliance on labor in an increasingly competitive labor market. The kitting process primarily consists of a manual operation with the use of several heat sealers, autobaggers, and both line and pack station style assembly.

Provided data includes aftermarket kit demand, packaging data for each kit, and a CAD drawing of the current facility layout. Our team plans to focus on three major areas of investigation: organizing part storage via a zoning system; reducing the overuse and subsequent downtime of autobaggers by strategically grouping parts within a kit; and improving process flow via layout change.

To establish the zoning system, we will use the kit demand data to better prioritize storage and reduce physical labor. Kit parts will be zoned based on their demand volumes. Additionally, the team has divided the kitting data equally to establish a sub-kitting system and other grouping parameters. This grouping will result in a reduction of autobags per kit. Finally, given the CAD drawing, we will investigate various layouts and utilize the Arena simulation tool to test their effectiveness.

Implementing these changes will allow Caterpillar to optimize their end-to-end kitting process in a realistic, simple, and efficient manner.

Michigan State University

Team Members (left to right)

Nicholas Caldwell

Chicago, Illinois

Isabella Cueny

Troy, Michigan

Sara Fusco

Plymouth, Michigan

Allie Percy

Troy, Michigan

Matthew Ginter

Walled Lake, Michigan

Caterpillar

Project Sponsors

Brian Uerkwitz

Lafayette, Indiana

Teaching Assistant

Sneha Abhyankar

Caterpillar: Kit Assembly Automation

Caterpillar is one of the world’s leading manufacturers of construction and mining equipment, engines, turbines, and locomotives. The company’s Product Support and Logistics Division assembles engine gasket repair kits that dealers order to support maintenance and repair of equipment in the field. On the main production line, there are 25 different kits of various demand that share 64 consistent part numbers. The parts are organized in drawers on the shelves above the line, and the full process of assembling these kits currently takes seven full-time employees to operate, with an average of 590 kits per day.

The sponsor is looking to incorporate some automation into the current kit assembly process in order to improve efficiency and lower labor costs. Our team has been tasked with finding creative solutions and opportunities to integrate automation which can then be presented to Caterpillar’s upper management. The goal is to propose equipment and processes, along with other relevant deliverables, to automate the assembly in order to maximize the reduction of the manual labor component and to increase productivity.

By calculating the cost of integration and through the implementation of various robotics, we have developed a floor plan that not only automates this current assembly kit process, but increases both productivity and efficiency as well. Our plan is set to take the place of the current manual setup and will provide Caterpillar the necessary tools it needs to better meet the demand of its customers.

Michigan State University

Team Members (left to right)

Maddie McDonough

Kennett Square, Pennsylvania

Sara Fan

Grand Rapids, Michigan

Ashley Binsfeld

Plymouth, Michigan

Jianing Wu

Shanghai, China

Colin Klein

Coldwater, Michigan

Caterpillar

Project Sponsors

Austin Ortiz

Morton, Illinois

Teaching Assistant

Ishaan Anand

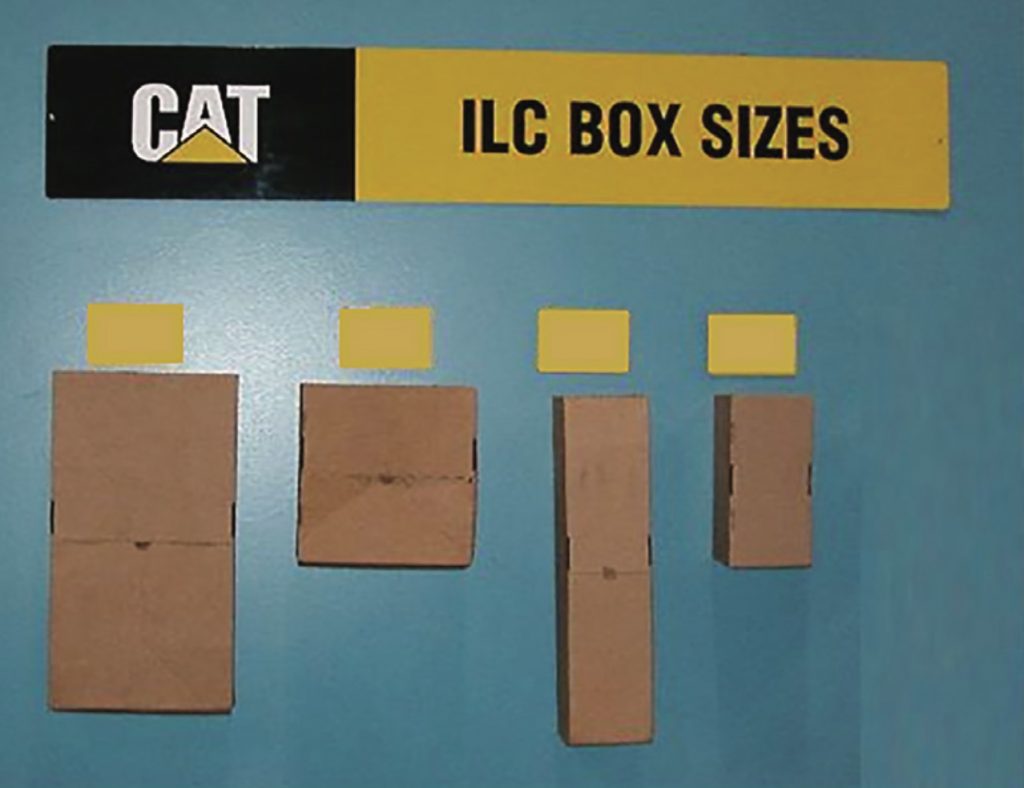

Caterpillar: Small Part Distribution Optimization

Caterpillar is an American Fortune 100 company that is a leader in manufacturing construction equipment. This project is based on Caterpillar’s ability to distribute and store common parts used in assembly lines across the globe. The Caterpillar Manufacturing Parts Nodes (MPN) Network uses a cardboard box as the main method and the goal is to determine if there is another method to use for distribution and storage. Typical parts stored in these boxes are nuts, bolts, and seals. Pieces per box can range from 2 to 10,000. The box quantities are determined by size and usage of each part. Currently, some boxes are packed completely full, while others are 90% empty. These boxes still take up the same amount of space, regardless of how many parts are in the box. This project will evaluate if a box is the optimal storage and distribution method for all common parts and investigate ways to reduce overall space requirements for the warehouse and/or the assembly line.

The opportunity our team is focusing on for this project is finding a more efficient way to store parts that do not utilize the entire box capacity. The parts that do not utilize the entire box and are not used frequently could be moved to a bin storage system, freeing up space on the gravity runs to store more frequently used parts. This would in turn reduce overall space requirements for the warehouse, and potentially the assembly line, while also decreasing transportation costs by reducing shipments of regularly used parts. With fewer orders, there could also be a decrease in the labor needed to fill orders and stock warehouse shelving.

Michigan State University

Team Members (left to right)

Rob Miller

Waterford, Michigan

Alena DeLong

Brighton, Michigan

Hassan Bennouna

Ann Arbor, Michigan

Kate Currier

Bloomfield Hills, Michigan

Neel Sopariwala

Surat, India

Caterpillar

Project Sponsors

Laura Cronkleton

Morton, Illinois

Teaching Assistant

Jose Naime

Clarience Technologies: Strategic Sourcing

Clarience Technologies LLC, owns a variety of brands within the transportation industry, which aims to provide customers with maximum visibility. Formerly Truck-Lite Holdings, the name was changed to Clarience Technologies, which is a combination of the words clarity and science. The organization known as Truck- Lite is now within Clarience Technologies’ family of brands. Brand subsidiaries include companies like RIGID, which makes high-end light attachments such as light bars on Jeeps. Other company brands include Echo, specializing in the production of emergency amber lighting, and Code 3, which produces the red and blue emergency lights used by firetrucks and police cars. Clarience Technologies prides itself as a leader in transportation visibility. It is not surprising that each of the company’s subsidiaries is number one in its market.

Clarience Technologies is looking for options closer to final manufacturing sites to source components. The Covid-19 pandemic has led to an increase in freight prices and lead times. Tariffs and political tensions have inflated costs throughout the supply chain as well. In addition, the visibility of certain products is very limited. By sourcing major components closer to final manufacturing sites, visibility should increase throughout the supply chain.

Our team is responsible for building a business case related to sourcing components to reduce costs and increase supply chain visibility. To achieve this, the team will contact a list of suppliers provided by Clarience to send Request For Quote. The commodities included in this Request For Quote are wire harnesses and diecasts. The business case provided will include a recommendation of suppliers that are capable of achieving Clarience’s goals.

Michigan State University

Team Members (left to right)

Gabby Aprilliano

Novi, Michigan

Meghan Sullivan

Plymouth, Michigan

Zach Rang

Naperville, Illinois

Jacob Spadafore

East Lansing, Michigan

Gage Warzecha

Oxford, Michigan

Clarience Technologies

Project Sponsors

James Heichel

Southfield, Michigan

Kevin Krause

Southfield, Michigan

Benjamin Lee

Southfield, Michigan

David McKean

Southfield, Michigan

Jeff Parmerlee

Southfield, Michigan

Teaching Assistant

Akash Mehrotra

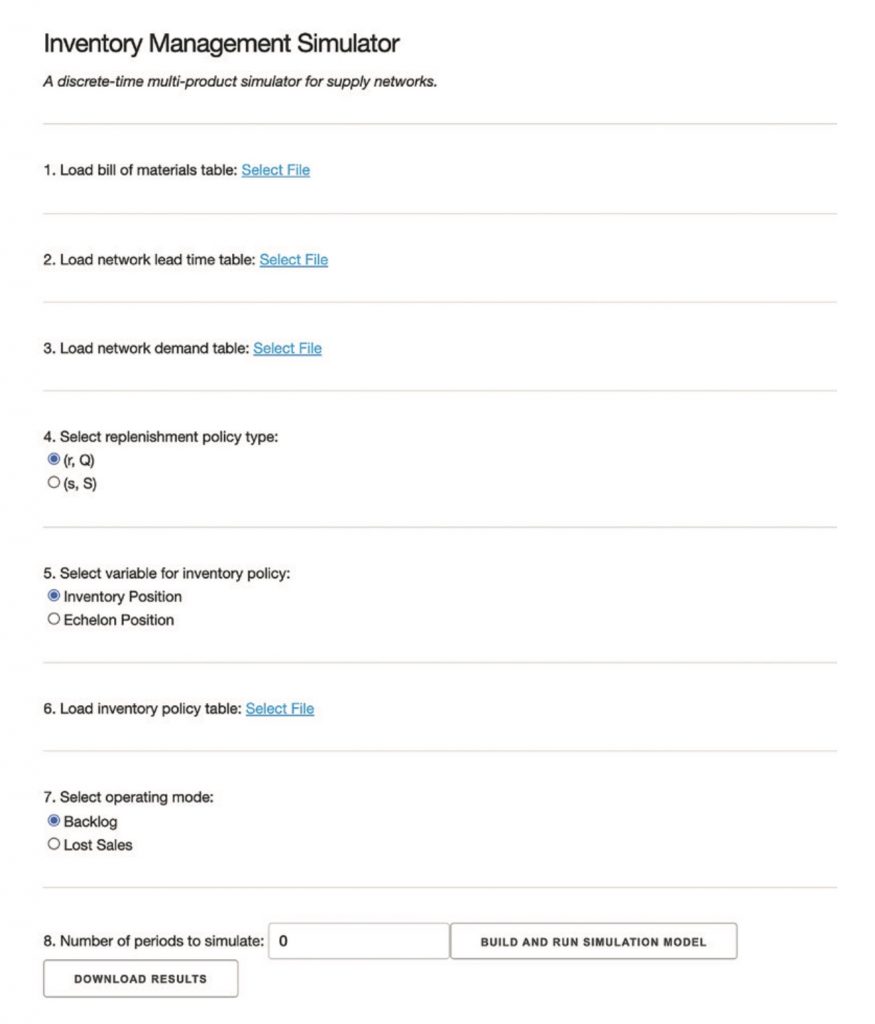

Dow Inc: Replicating Supply Chain Inventories and Policies

Founded in 1897 by chemist Herbert Dow, after he discovered how to extract bromine from the ground, Dow started selling bleach and potassium bromide. Since then, Dow has grown to become the most innovative, inclusive, and sustainable materials science company, with a purpose to deliver sustainable solutions for the future of the world. Operating in 31 countries with 106 manufacturing sites and over 35,000 employees, Dow is a global powerhouse in their industries. From supplying chemicals to plastics to agricultural products, Dow produced about $39 billion in sales in 2020.

Dow has provided the amazing opportunity to replicate supply chain networks for inventory simulation and policy design. The data which Dow supplies will be run through a newly designed supply chain simulation system coded with Julia, a new coding language. This provides the team opportunities to learn about Dow’s supply chain policies, automate network building, and to explore replenishment policies. With these opportunities Dow is providing, it specifically focuses on learning about inventory management policies, data interpretation and cleanup, and echelon structured inventory strategies.

The work and reflection that goes into the inventory simulation and policy design will undoubtedly improve the overall efficiency of the supply chain network for Dow’s inventory. Inputs into the simulation, such as the bill of materials, Replenishment Policy type, lead timetables, and the inventory policy will help in analyzing and proctoring the continuous changes in market demand, inventory levels, total pipeline, and many more, which are paramount to the businesses operation. Also, we will be able to locate best reorder points for product inventories as well as identify best policies and strategies for inventory management for certain products, which will be deemed a very useful and crucial supply chain tactic for Dow.

Michigan State University

Team Members (left to right)

Taman Mukkatira

Farmington Hills, Michigan

Ryan Jorgensen

Trenton, Michigan

Matis Butlevics

Grand Rapids, Michigan

Jason Wenner

Novi, Michigan

Aagosh Chaudhary

Bhopal, India

Dow Inc.

Project Sponsors

Kyle Harshbarger

Midland, Michigan

Hector Perez Parra

Pittsburgh, Pennsylvania

Jacob Templet

Midland, Michigan

Teaching Assistant

Jose Naime

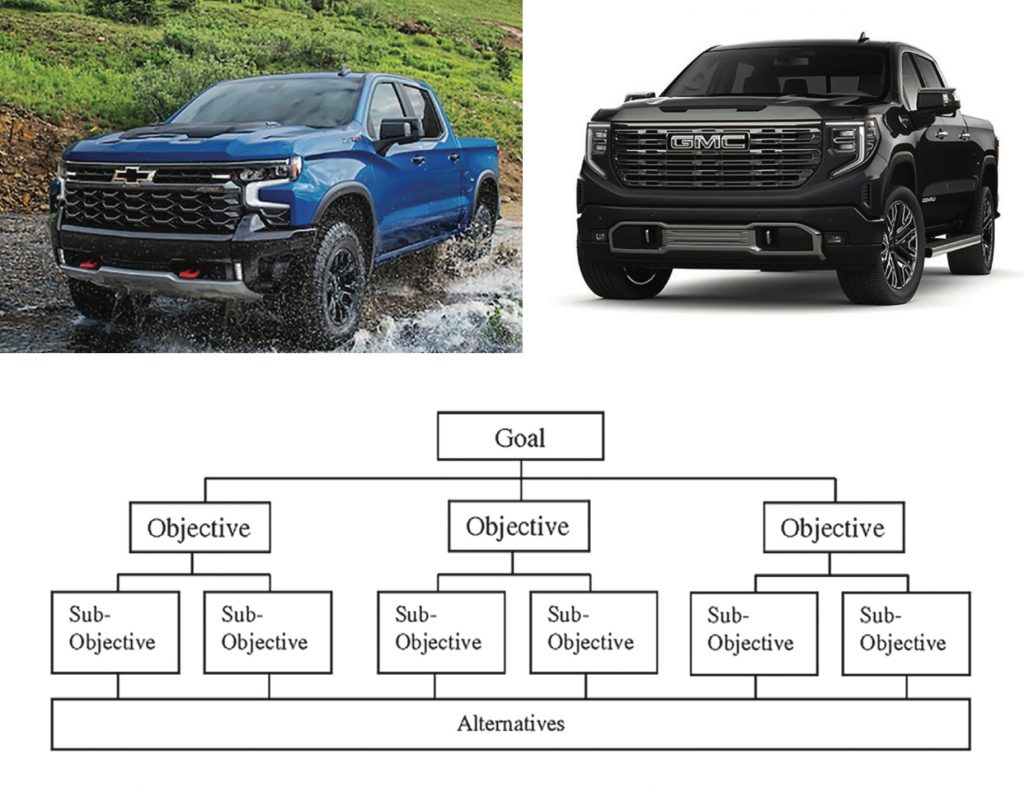

General Motors: Supplier Risk Assessment and Key Risk Indicators

General Motors has tasked our team to develop inferences about their supply chain. These inferences are to be developed from key risk indicators within their supply chain that our team will further discover, analyze, and explain from quantitative metrics. To create a cohesive analysis of General Motors’ supply chain, the team will focus on models exclusively produced and sold in North America. Specifically, the focus of this project is on the supply chain related risks for two of General Motors’ highest selling vehicles, the Chevrolet Silverado and GMC Sierra half-ton pickup trucks. Within these two models, the team will be identifying primary risk drivers in the supply chain network through the quantitative analysis of different variables, such as an Analytical Hierarchy Process model. These different variables will be broken down into three specific sectors. The first will pertain to COVID-19 and how the global pandemic could further impact the General Motors supply chain network. Next, the team will research the lead times, delays, reasons for delay, etc. between the manufacturing facilities and the dealerships to understand the logistical risks that are involved in the production of these two vehicles. Finally, the team will dive into the production and plant operations for each vehicle to determine impediments potentially associated in the making of these pickup trucks. Overall, the overarching goal is to present General Motors with a visual representation of these key risk indicators, and their corresponding metrics. In turn, these metrics and key risk indicators will help General Motors on their supply chain resiliency journey and drive meaningful change throughout the enterprise.

Michigan State University

Team Members (left to right)

Nick Howard

Troy, Michigan

Evan Leslie

South Lyon, Michigan

Roenik Master

Canton, Michigan

Ben Luci

St. Charles, Illinois

Mariana Merandi

Shelby Township, Michigan

General Motors

Project Sponsors

Hilary Pietila

Warren, Michigan

Teaching Assistant

Sneha Abhyankar

Genpact: Improving Supply Chain Processes

Genpact, based out of New York, NY, is a global professional services firm focused on business transformation. Founded in 2005, Genpact currently has over 80,000 employees in more than 25 countries working to solve supply chain issues in multiple industries.

Genpact’s client, acting under the alias, “G-Mart,” has pervasive problems throughout its supply chain resulting in higher costs and client satisfaction issues. G-Mart’s issues stem from a lack of inventory level visibility. There have also been issues with merchandising, rising costs, stockouts, port congestion, transportation capacity issues, siloed operations, and other supply chain operations. As these concerns continue, customer service and satisfaction are suffering tremendously. To address these issues, our team has decided to focus on reforming G-Mart’s current supply chain processes. This will create a more cohesive flow in the organization’s procedures, which will address issues such as the siloed operations and capacity limitations, as well as many other supply chain issues.

Our team developed new procedures for the company, as well as cost savings analyses to mitigate new supply and capacity planning issues. We also constructed a roadmap to help G-Mart execute initiatives that implement the new strategies in both qualitative and quantitative approaches. The scope of the project is to stabilize G-Mart’s supply chain by executing improved operational processes. The results of the processes and roadmap being implemented will improve demand planning in order to improve all supply chain operations. Increased supply chain functionality will improve the forecasting of demand for customers and increase customer satisfaction. Once this roadmap has been implemented, G-Mart will have a highly responsive and well-planned supply chain that will be able to handle fluctuating demand from customers. This approach will improve supply chain operations for the company and will increase customer satisfaction in the long run.

Michigan State University

Team Members (left to right)

Kevin Adams

Battle Creek, Michigan

Kyle Hanlon

Grand Rapids, Michigan

Molly Dunlap

Birmingham, Michigan

Michael Conniff

Northville, Michigan

Lynsey Davison

Grand Rapids, Michigan

Jack Downs

Farmington Hills, Michigan

Genpact

Project Sponsors

Jesse Davidson

Falls Church, Virginia

Jeff Kazanow

Atlanta, Georgia

John Richardson

Little Rock, Arizona

Perryn Stewart

Charlotte, North Carolina

Austin Todd

Falls Church, Virginia

Teaching Assistant

Ishaan Anand

Guardian Glass: Stock Level Optimization Tool

Guardian Glass is one branch of the globally expansive Guardian Industries. Guardian Glass is a privately held glass manufacturer headquartered in Auburn Hills, Michigan. They manufacture approximately 500 km of float glass each day for commercial, residential, and automotive applications. With more than 160 countries served across five continents, they are one of the world leaders in glass production.

Guardian Glass has completed some of the most spectacular buildings in the world while maintaining a zero net energy consumption, notably, the VISA Headquarters in Dubai; Le Cristallin in Boulogne-Billancourt, France; and the Bioengineering Research Facility at Michigan State University.

Managing and evaluating necessary inventory is only a fraction of the work done at Guardian’s plant in Carleton, Michigan. However, it is one of the most important tasks for their success. For this project, the team was tasked with developing an automated tool that enables real-time calculations and evaluation of min and max stock levels. Our team will also create a statistical method to determine which products should be used as “ make-to-stock.”

The analysis will consider historical sales data and consumption data to provide insight into how Guardian should be stocking different SKUs across manufacturing facilities. Production cycles and variability will also be factored. The intent is to update inventory levels based on future demand. This tool is one that hopefully will impact not only Guardian’s plant in Carleton, but also their worldwide facilities.

The tool will be easily adaptable to integrate with a future ERP and will be an input for Guardian’s scheduling and planning processes. A visual representation of the data, created in PowerBI, will also be constructed as a secondary element of the tool. This project will reduce Guardian’s working capital, identify opportunities for SKU rationalization, and enable them to better serve clientele.costs for both the supplier and the buyer should be minimized.

Michigan State University

Team Members (left to right)

Riley Fisher

Birmingham, Michigan

Sarah Littlefield

Beverly Hills, Michigan

Ana Starks

Grand Rapids, Michigan

Logan Susalla

Sterling Heights, Michigan

Hannah Schecklman

Appleton, Wisconsin

Natalie Burt

Pleasant Ridge, Michigan

Guardian Glass

Project Sponsors

Rachel Gibson

Auburn Hills, Michigan

Vivian Schramm

Auburn Hills, Michigan

Nick Seeley

Auburn Hills, Michigan

Teaching Assistant

Jose Naime

Intel: Common Items Bulk Buy Strategy

Intel is an American multinational corporation and technology company headquartered in Santa Clara, California. Aside from being the world’s largest semiconductor chip manufacturer by revenue, Intel also manufactures and supplies microprocessors, motherboard chipsets, and other processing components for computer manufacturers like Dell, Lenovo, and HP. With technology advancing at an exponential rate along with the crippling effects of Covid-19 on the semiconductor industry, Intel is looking for inventory solutions to close the gap between supply and demand.

Intel has a subset of Tier 2 suppliers who provide ancillary equipment in alignment with production equipment installation. Often, these Tier 2 suppliers provide several common items across multiple OEM production machine sets. Our team has been given past, present, and future purchasing data for one production facility. Intel has tasked our team with evaluating the commonalities of items across OEM production machine sets to identify significant correlation. Further, we are expected to propose Common Items Bulk Buy Forecasting and Hedging based upon machine sets with the greatest commonality, longest lead time, and most often late tender from the supplier.

Our team will use methods including but not limited to Economic Order Quantity, ABC categorization of inventory, and Excel models and analysis. Once commonalities have been identified, we will use Tableau to graphically display their data and findings to the company. The displays will include interactive dashboards that Intel will be able to utilize in the present and future. We will identify the best dates and optimum quantities to purchase parts, with the goal of improving Intel’s purchasing efficiency and reducing inventory costs.

Michigan State University

Team Members (left to right)

Mackenzie Rampy

Fenton, Michigan

Rachel Hamilton

Wyandotte, Michigan

Jack Metzger

Taylor, Michigan

Nick Ansted

New Baltimore, Michigan

Johnny Bean

Novi, Michigan

Gage Chittenden

Canton, Michigan

Intel

Project Sponsors

Beth Adkison Chandler, Arizona

Erik Hertzler Chandler, Arizona

Teaching Assistant

Sneha Abhyankar

Intel: Consolidated Shipping Project

Intel is a driver of innovation across industries in creating world- changing technology. Intel has been one of the world leaders in computer technology since its founding in 1968. As an industry leader, Intel seeks to optimize and increase efficiency throughout its business model to meet customer needs. Shipping efficiency is critical to meeting those needs.

Intel has encountered a similar problem that many other companies are facing during the COVID-19 pandemic. The worldwide shipping shortage and ever-growing lead times have had a negative impact on the production and efficiency of Intel’s shipping. Shipping container costs have risen 300% per container and lead times have gone from 30 to 100 days for ocean shipping. To combat these growing costs and lead times, Intel plans to consolidate shipping transactions and lower the number of shipping containers needed to transport their capital goods from suppliers to Intel factories.

Intel has tasked our team with looking into the future of Intel shipping through 2026 to lower shipping costs. This was done by creating processes and procedures for consolidating shipments from multiple suppliers in the same geographical areas within similar time zones, as well as similar shipped-to and shipped-from locations. We conducted exploratory and predictive analyses on transaction data through Excel, Tableau, and Data Studio to find which strategy fits Intel’s shipping best.

Our end goal is to propose a consolidation strategy to Intel that will lower ocean shipping costs through 2026 and can be used for future Intel shipments. We intend to present a thorough consolidation program as well as a cost analysis to demonstrate the savings the program will provide.

Michigan State University

Team Members (left to right)

Ryan Flint

Midland, Michigan

Dan Brandolino

Elmhurst, Illinois

Alexis Whiteman

Midland, Michigan

Brooke Popour

New Baltimore, Michigan

Ashlynn Biondo

Rochester Hills,Michigan

Intel

Project Sponsors

Erik Hertzler

Lansing, Michigan

Teaching Assistant

Ishaan Anand

RPM Freight Systems: Reducing the Carbon Footprint

For this project, RPM asked our team to attack the biggest issues facing the company as well as the environment, CO2 emissions. The importance of reducing CO2 emissions has been brought to light for a while now but as far as for a logistics company, where they own none of the vehicles and only oversee them, this has never been done before.

Since RPM does not own any of the vehicles that are transporting the cargo, our team must find a creative solution to solve this. Before reducing any of the emissions, we must get a baseline of RPM’s CO2 emissions to calculate a feasible reduction. Gathering data from the sponsor as well as educated assumptions, our team will be able to estimate the emissions released from trucks for a given trip, as well as the yearly emissions released.

One of the many ideas we came up with was to team up with a company specializing in offsetting emissions and process some of the payments to drivers through them. This would provide the company with some reductions in the total emissions they produce, as well as making the world more sustainable for generations to come.

Michigan State University

Team Members (left to right)

John Hryciuk

Grosse Pointe, Michigan

Klyon Govender

Rochester Hills, Michigan

Rylee Manriquez

Lake Orion, Michigan

Sara Ortisi

Shelby Township, Michigan

Megan Schwartz

Marietta, Georgia

RPM

Project Sponsors

Rick Grubb

Royal Oak, Michigan

Brad Janer

Royal Oak, Michigan

Frank Soehnge

Royal Oak, Michigan

Teaching Assistant

Jose Naime

RPM Freight Systems: Capacity Aggregation

RPM Freight Systems is a logistics company that specializes in freight and finished vehicle transportation. They currently have over 2000 customers and partner with more than 30,000 carriers.

RPM is currently looking to identify industry-preferred communication methods in order to employ standard communication processes between RPM and carriers, as well as optimize carrier capacity. Our team has been working with RPM and researching the carriers’ current methods of communication to gain perspective on which methods are currently being utilized and how they can be improved.

Communication plays a vital role in how and with whom RPM does business. Inconsistencies in communication methods are a problem across the logistics industry, and RPM is looking to identify which communication method carriers prefer to use across the board. One of the first steps of this project was the creation of surveys that would gather various perspectives from both external carriers as well as RPM’s employees. Using survey data from carriers around their communication obstacles and successes, we are conducting an analysis of different methods to allow RPM to reach as many carriers as possible and ultimately optimize carrier capacity.

By finding a method of communication that is preferred by carriers, RPM will be able to create stronger relationships with those carriers. As a result of stronger relationships, RPM will be able to become a preferred shipper in the industry.

Michigan State University

Team Members (left to right)

Antonio Vushaj

Cape Coral, Florida

Emily Fischer

Canton, Michigan

Noelle Rogalski

Plymouth, Michigan

Carson Burroughs

Romeo, Michigan

RPM

Project Sponsors

Brian Husman

Royal Oak, Michigan

Navnik Shivadas

Royal Oak, Michigan

Teaching Assistant

Sneha Abhyankar

RPM Freight Systems: Streamlining the Home Delivery & Pick-Up Processes

RPM Freight Systems (RPM), founded in 2012, is one of the fastest-growing private logistics companies in North America. The company operates as one of the nation’s top quality logistics brokerages and facilitates on-demand transportation services for businesses that are experiencing unexpected insufficiencies. RPM has a large transportation network of freight systems partnering with 30,000+ carriers across the United States and Eastern Europe. Currently, RPM transports 30,000+ automobile units a month and is looking to expand upon that market.

With auto-manufacturers adopting e-commerce automobile sales, and the direct delivery to consumer market growing, RPM is seeking to capitalize on the home delivery and pickup of vehicles using their vast logistics network. Our team is tasked with developing an in-depth market study of the home delivery and pick-up processes to further aid RPM’s goals.

In order to generate an impactful project for RPM, the team delivered various reports including cost analysis breakdowns, quantitative and qualitative data, Porter’s Five Forces models, market research reports, SWOT analysis reports, and other market measures. With these reports, we provided a data driven breakdown of RPM’s competitive position to enter this direct-to- consumer car market, as well as generated a measurable standard from which RPM can gauge their market opportunities alongside customer satisfaction and areas of vulnerability.

By applying the best market practices outlined in this project, the company will be able to effectively utilize their current model of operations and capitalize on the supply chain of the growing online auto retail market.

Michigan State University

Team Members (left to right)

Jordan Guske

New Baltimore, Michigan

Maddie Guter

Ridgefield, Connecticut

Hope McMullen

Livonia, Michigan

Brittney Schelling

Grand Rapids, Michigan

Justin Thomas

Sterling Heights, Michigan

RPM

Project Sponsors

Navnik Shivadas

Royal Oak, Michigan

Teaching Assistant

Akash Mehrotra

RENK: Best-in-Class Key Performance Indicators

RENK was founded in 1873 by Johann Julius Renk, who started as a trainee mechanic and ended as a pioneer in the industrial age through development of revolutionary drive technology. RENK started as a production company producing wheel gears and quickly made it into the military scene as World War II started. The company gained notoriety for building the first reversing gear units for marine applications and achieved a record for building the fastest gear in the world. RENK has continued to evolve and is a military contractor performing on the global market.

Today RENK America is a leading global supplier of best-in- class mobility solutions. They specifically work with military combat vehicles to manufacture engines and transmissions for tanks. This project helps define and elevate key performance indicators based on importance and supply chain best practices in the industry. As a company that is continually evolving, these indicators are being tracked through internal reporting and Sisense, a data analytics software that helps visualize and organize data.

Utilizing Sisense has been an integral part of visualizing RENK’s KPIs and providing a user-friendly dashboard to key stakeholders. Sisense serves as a central database for RENK’s KPIs and firm information and then utilizes visualizations to tell a story with this information. Through both automatic uploads from their ERP and manual entries from Excel, this dashboard incorporates critical reports into Sisense and provides RENK with a centralized dashboard that offers transparency to the procurement team. The final dashboard shows the procurement team the most critical information which will affect their day-to-day operations, offering direction for their work in the immediate future. In turn, this information can be used to increase throughput, reduce costs, and improve execution.

Michigan State University

Team Members (left to right)

Valerie White

Livonia, Michigan

Courtney Faurot

Chicago, Illinois

Alex Beger

Shelby Township, Michigan

Ben Samson

Macomb, Michigan

Chris DeClercq

Shelby Township, Michigan

RENK

Project Sponsors

Chris Brown

Muskegon, Michgian

Chase Kloka

Muskegon, Michigan

Jeff Langois

Muskegon, Michigan

Tanner Myers

Muskegon, Michigan

Teaching Assistant

Akash Mehrotra

RENK: Purchase Order Compliance Package Process

RENK is a worldwide company that leads manufacturing in the production of defense vehicle transmissions and components. Due to its involvement in federal vehicle production, the purchase order process at RENK is heavily documented and time- consuming, requiring a “package” of paperwork documenting the process in detail. It involves many variables which, due to the detail required, increases the possibility of error with every step.

Our team was asked to decrease risk throughout the purchasing process by simplifying it. We first took a trip to RENK’s location in Muskegon, diving firsthand into the process. This allowed us to determine the thoroughness needed, as well as the excessive complication of the problem. Following this, we worked on their deliverable; a simplifying tool for RENK to implement in their everyday work.

By combining experience learned in classes, as well as researching current purchasing process innovations, our team collaboratively created a tool to improve the efficiency of the purchase order compliance package creation process at RENK. The tool included using Microsoft Excel to combine all documentation into one checklist, which could easily be edited and summarized.

Throughout the semester, we made progress in streamlining the purchase order compliance package creation process, reducing time requirements for buyers, and cutting costs for RENK. Our team delivered a smart checklist to provide a concise template for the purchase order package creation system and provide a foundation for further improvements to the purchasing process.

Michigan State University

Team Members (left to right)

Cole Gibbs

Bloomfield Hills, Michigan

Kory Ernster

Novi, Michigan

Addison Dunham

Leslie, Michigan

Maggie Lear

St. Joseph, Michigan

RENK

Project Sponsors

Sarah Batchelder

Muskegon, Michigan

Rick Douglas

Muskegon, Michigan

Chase Kloka

Muskegon, Michigan

Ryan Norwood

Muskegon, Michigan

Mark Zelek

Muskegon, Michigan

Teaching Assistant

Akash Mehrotra

Rockwell Automation: Warehouse Manufacturing and Bin Optimization

Founded in 1903, Rockwell Automation is a Fortune 500 company headquartered in Milwaukee, Wisconsin. The company’s mission is to improve the quality of life by making the world more productive and sustainable by providing industrial automation and digital transformation.

Rockwell is facing warehouse utilization issues in its Mequon plant due to a lack of efficiency with the company’s internal material movement and tracking metrics. This results in unnecessary downtime, lost profit and/or late shipments. Our team was tasked to build an inventory movement tracking platform under the preferred Power BI program. This tool is user-friendly and can be easily understood by Rockwell’s employees. To create this, we analyzed warehouse movement data and investigated the warehouse layout to enhance the overall efficiency of its product movement. Rockwell’s SAP and ERP system data are not involved in this project.

Another aspect of this project is optimizing bin storage within the Mequon plant. Because the warehouse is on the smaller side, it is important that every bit of storage is being used. Within the team’s created system, any product that has not been used in a certain time will be recognized and potentially relocated to the larger plant in Milwaukee.

With our finalized project, Rockwell is able to improve distribution routes and reduce its production downtime in the Mequon warehouse. Reducing its downtime benefits the company by distributing more of its products to their customers as well as saving time and energy within the plant.

Michigan State University

Team Members (left to right)

Julia Wallace

Fraser, Michigan

Viktoria Mihailovic

Sterling Heights, Michigan

Olivia Gongos

Rochester, Michigan

Joe Zhou

Chongqing, China

Donny Hernandez

Grand Rapids, Michigan

Rockwell Automation

Project Sponsors

Carrie Haver

Mequon, Wisconsin

Alex Roadt

Mequon, Wisconsin

Brandon Spires

Mayfield Heights, Ohio

Teaching Assistant

Akash Mehrotra

SNACKWERKS: Single Station Automation Project

Snackwerks is a contract food manufacturing company devoted to producing high quality products, upholding strong safety standards, and maintaining lean processing lines. Providing an exceptional, first-class experience to all customers is Snackwerks’ number one goal.

To produce with maximum efficiency, maintain customer satisfaction, and increase profitability, Snackwerks must reevaluate their manufacturing practices. Currently, the snack packaging process at Snackwerks is done completely manually. This mundane and routine process is utilizing scarce human resources and preventing higher order work from being done elsewhere in the plant. For throughput to match demand rate and to increase efficiency of the assembly line, an automated solution is ideal. This would allow for a more consistent production process without the potential of human error.

The automated solution is to completely replace the work of two or more humans. This includes handling various pouch sizes, collection of various products into the pouch, and placing the pouch onto a conveyor for sealing. To successfully do this, proper planning and analysis must take place. This involves determining the weaknesses of the current setup, evaluating potential suppliers of automated solutions, ensuring operational and technical capacity can be met, financial analysis, and most importantly, compatibility with food safety standards. Safety is of huge concern because the production line operates three shifts a day, five days a week with interchanging products. This means it is necessary to have the ability to properly clean all machinery with ease. The success of this project will further Snackwerks’ growth as a premier contract manufacturer in the food industry.

Michigan State University

Team Members (left to right)

Daniel Miller

Ann Arbor, Michigan

Jack Gallagher

Battle Creek, Michigan

John Loch

Clarkston, Michigan

Kara Rocheleau

Northville, Michigan

Cat Jicomelli

Pittsburgh, Pennsylvania

Smithfield Foods

Project Sponsors

Dylan Clark

Battle Creek, Michigan

Jeff Grogg

Battle Creek, Michigan

Doug Rock

Battle Creek, Michigan

Teaching Assistant

Jose Naime

Tenneco: Cost Modeling and Verification in the Global Automotive Aftermarket

Tenneco became their own entity in 1999. It all started with a conglomerate consisting of six different businesses: chemicals, automotive, shipbuilding, gas transmission, farm, and construction equipment. This was until the company decided to divest in their businesses, leaving Tenneco Automotive as the remaining business of the original company. Tenneco remains strong with their original businesses and aftermarket brands due to keeping their roots with brands such as Monroe and Walker.

In 2005, Tenneco decided to rebrand their company so that they could best represent the expanding number of markets they are serving. The company had expanded their global footprint to keep up with the evolving world of automotive to become one of the first automotive suppliers to have the opportunity to work with China.

Headquartered in Lake Forest, Illinois, Tenneco has a global annual turnover of $4.4 billion and more than 19,000 employees. Tenneco is one of the world’s leading designers, manufacturers and marketers of automotive products for original equipment and provides services of high quality for aftermarket customers. By pushing advancements in global mobility, Tenneco delivers technology solutions in their four business groups, Motorparts, Performance Solutions, Clean Air, and Powertrain. These advancements are key to Tenneco’s involvement in diversifying global markets.

Tenneco’s purchasing team is enlisting the help of our team to perform a “Should – Cost” model to analyze the performance and cost of three of Tenneco’s top product lines – Spring Coils, Back Plates, and Hub Assemblies. The team has created an eRFP to help Tenneco review current suppliers, along with proposals for benchmarking with new suppliers.

Our team will be using our extensive knowledge of Excel, Tableau, PowerBI, and RStudio to enhance Tenneco’s competitive advantage and generate market share growth opportunities for the company.

Michigan State University

Team Members (left to right)

Nick Schellmat

Troy, Michigan

Samah Maaita

Canton, Michigan

Brianna Coeling

Troy, Michigan

Pookie Khounsombat

Holland, Michigan

Andrew Kim

Troy, Michigan

Not Pictured

Zihan Wang

Liuzhou, China

General Motors

Project Sponsors

Jonathan Lakin

Southfield, Michigan

Teaching Assistant

Jose Naime