One goal of the MSU Mechanical Engineering Program is to educate engineers who are prepared to lead, create, and innovate as their professional or graduate careers evolve. The Mechanical Engineering Design Program is the key element of the curriculum that supports this goal. There are five required design courses in the program which provide our students with eight hands-on, team-based, ‘design, test and build’ projects, and numerous opportunities to practice and refine their written, oral, poster, and video presentation skills. The Design Program in Mechanical Engineering has attracted national recognition on many occasions and helps to distinguish the ME program as one of the best in the country.

For information on becoming a project sponsor, please contact Jim Lang.

The following were the project sponsors and projects for Spring 2019:

MSU Solar Racing Team: Feasibility of a Titanium Solar Car Chassis

The Michigan State University Solar Racing team is a student-led organization that designs and builds full-sized solar electric vehicles. Beginning in fall of 2017, the team started designing a two-person solar car to compete in the cruiser class of the 2020 American Solar Challenge. Currently, the design phase is finished and the construction of the car is almost complete. The current car, Aurora, is designed with a steel tube chassis that adheres to the regulations and specifications of the American Solar Challenge.

Our team was asked to conduct a feasibility analysis of producing a titanium chassis for a solar vehicle. To achieve this goal, the current steel tube chassis was considered as a benchmark for analyzing the benefits of titanium. We have created an extensive 3-dimensional model of a new titanium chassis that fits into the body of the Aurora. A cost analysis and a finite element analysis were conducted for the newly designed chassis. A manufacturing plan was created so this chassis could potentially be implemented into Aurora’s body. All regulations from the American Solar Challenge were considered and designed for this new chassis. The success of this study will provide insight for the benefits and drawbacks of incorporating titanium rather than steel into a car chassis.

MSU Adaptive Sports & Recreation Club: Hand-Cycle Propulsion Adapter

The MSU Adaptive Sports and Recreation Club is a registered student organization that serves as a free program open to athletes with physical disabilities, able-bodied volunteers, and residents of the greater East Lansing community. The club strives to promote the physical health, social behavior, and psychological wellness of its members. This is achieved by providing recreational activity opportunities to individuals with physical disabilities by ensuring a wide variety of quality wheelchair and adaptive sport equipment and facilities.

Our team was asked to design a hand-cycle propulsion adapter that enables the rider to have increased control over speed and direction. The intended users of the propulsion adapter are those with limited use of lower limbs, as well as asymmetry between their dominant and non-dominant sides. The design needs to accommodate limited strength and range of motion. In order to do this, the propulsion and steering need to be two separate functions that are easily accessible and limit discomfort to the users. These two functions must also be interchangeable depending on which arm the rider prefers to use. It is important that this product provide a level of security and safety, which in addition to functionality, is the reason many members feel the product is unusable.

ArcelorMittal: Steel Coil Stretch Wrap Machine

ArcelorMittal is a steel and mining company that is one of the top suppliers of steel products for major markets such as construction, appliances, automotive, and packaging. With its nearly 200,000 employees across 60 countries, ArcelorMittal produces 113 million tons of crude steel per year. They are the largest producer of steel in North and South America and one of the largest producers of iron ore in the world. ArcelorMittal’s headquarters is located in Luxembourg, and they operate six steelmaking plants located within the Midwest United States.

Our team has designed a standalone process line for the wrapping of multiple steel coils for a shipping warehouse at the Burns Harbor, Indiana facility. The design includes a stretch wrap machine and a conveyor system that replaces the need for operators to manually wrap the steel coils. In doing so, the new system decreases the ergonomic issues related to manually wrapping the coils, as well as reducing the number of operators needed in the warehouse per shift. The system works alongside the overhead crane in the warehouse to prepare the coils before they are shipped to customers.

Ingersoll Rand – Trane: Indoor CSAA Unit Shipping Protection

Ingersoll Rand provides products, services, and solutions to improve the quality and comfort of air in homes and buildings across the globe, as well as to transport and protect food and perishables. An important aspect of transporting such valuable equipment is protection from rain, debris, and other factors that come from moving individual CSAA indoor units to homes and businesses. Because CSAA indoor units are shipped on open flatbed trucks, are not painted, are often shipped with openings and open ends, and shipped with various control and electrical boxes mounted to the outside of the units, shipping protection covers are used to protect the units before they are sealed and secured for transportation. The current design involves integrating hexacomb panels with house-made support brackets and corner boards to create a protected environment for each unit to be safely transported without being damaged or compromised.

Our team’s project was to model, build, and test a revised design based on the existing shipping panels used to protect air handling units during transport. The panels will be used in conjunction with plastic wrapping to keep wind, rain, and debris from damaging the air handlers. This design will also be able to be scaled accordingly to fit other sizes of CSAA indoor units. The goal of the new design is to reduce weight and decrease costs while retaining the durability and weatherproofing protection of the previous iteration. The new prototype was tested in real shipments between various Kentucky plants to ensure a successful solution. With the new design, Ingersoll Rand will be able to reduce costs while maintaining their confidence in the shipping containers to protect the valuable cargo.

Swagelok: Custom Solutions Fixture Design

Swagelok, headquartered in Solon, Ohio, is a global fluid system component supplier that offers a variety of fluid transport and sealing components as well as custom assemblies for its customers. Known for producing a variety of fluid and gas transport products, Swagelok additionally offers metal tubing for custom fluid system assemblies. In order to uphold their values of quality, customer focus, and continuous improvement, Swagelok is interested in optimizing their current tube handling processes. Their current methods of cutting and deburring tubing, while feasible, can be improved to increase Swagelok’s productivity.

Our team focused on the improvement of Swagelok’s processes for measuring, cutting, moving, and deburring metal tubing. The current cutting process involves inefficient handling and creates burrs which must be removed by hand. The designed solution for Swagelok must provide a loading station nearby for cutting and deburring the tube. It must also provide a method to measure the stainless-steel tubing with increased precision. The inefficient process of deburring by hand must be replaced with a safe, easy-to-use, mechanized, and ergonomic device that will increase the speed of the deburring process. Furthermore, the deburring device must align with the cutting process to streamline the product flow. With the implementation of these components in their cutting and deburring processes, there will be an increase in efficiency and productivity while also providing both physical and environmental improvements at Swagelok.

USS Battleship New Jersey: Modeling Steering & Propulsion Systems

The USS New Jersey is an Iowa-class battleship in the United States Navy that was commissioned 4 different times between 1943 and 1991. The New Jersey was among the last battleships ordered for service by the United States government. The USS New Jersey participated in World War II, the Korean War, the Vietnam War, and the Lebanese Civil War and is the most decorated Battleship in the U.S. Navy. In 1991, the USS New Jersey was decommissioned for the final time and became a museum ship in Camden, New Jersey. The USS New Jersey still serves as a museum ship to this day, with the goal of restoring, preserving, exhibiting, and interpreting the history of the ship to visitors.

Our team was tasked with demonstrating the ship’s propulsion and steering system to museum guests. The Battleship New Jersey Museum is currently in the process of opening up the boiler and engine rooms for tours and would like to display the massive size and power of the propellers and steering system to guests. Our team developed a virtual reality representation of the underwater exterior of the USS New Jersey. This VR tour allows museum guests to see the enormous size of the propulsion and steering system in a manner that is not possible though physical models. This project greatly enhances the visitor experience at the museum, providing guests of all ages with an exciting view of the underwater area of the ship.

MSU Department of Mechanical Engineering: Device to Prep Exams for Electronic Scanning

Michigan State University is a public research university located in East Lansing, Michigan. There are over 5,000 students enrolled in the College of Engineering, most of whom will be taking examinations each semester. One specific area needing improvement is the device currently used to prepare exams to be scanned. In attempts to incorporate technology into the classroom, exams are scanned and sent directly to students. Before scanning the exams, the staples must be removed. The current protocol is to remove the staples from the exams by using a paper cutter to slice off the corners containing the staples. The paper cutter used is capable of only slicing about 10 sheets of paper at a time. Also, the blade is exposed, which makes this a tedious, potentially dangerous, and time-consuming process.

Our team designed and manufactured multiple devices to remove the staples, to improve upon the current method. These devices will be used by different departments within the College of Engineering. The focus was to design devices that are relatively safe, efficient, and easy to operate. The devices must also be durable enough to withstand ~10,000 exams per semester. With the new devices, teaching assistants and professors can reallocate the time spent removing staples to grading and returning the exams more quickly.

Michigan AgrAbility: Folding Tractor Step Overlay

AgrAbility was established at both the national and regional level by the 1990 Farm Bill to assist agricultural workers who are in need of services and networking. Every division of AgrAbility is partnered with both a land grant university and a nonprofit organization. The goal is to supply aid to those who are disabled. These disabilities include spinal cord injuries, amputations, hearing impairments, and arthritis. The 2012 Census of Agriculture estimates that over 1,900 farm workers per year in Michigan are in need of AgrAbility’s services. Through the services that are provided to rural communities across the nation, living conditions are improved and independence is returned to those farm workers.

Our team has created an attachable extension step that aids a local farmer struggling with severe arthritis. This extension step reduces strain on the farmer’s knees, while providing easier access to the tractor on a daily basis. During operation, the tractor step is stowed in a position that interferes neither with the ground nor with its surroundings. This position also allows operators that do not require assistance to use the steps normally. The newly developed design will improve the local farmer’s ability to perform daily tasks and prolong his work life.

McLaren Greater Lansing: Rehabilitation Services Leg Press

McLaren Health Care, headquartered in Grand Blanc, Michigan, is a diverse health care network dedicated to quality and evidence-based patient care. The McLaren system includes 14 hospitals, ambulatory surgery centers, imaging centers, and a primary and specialty care physician network. McLaren’s Greater Lansing rehabilitation and therapy services is a sector focused on treating both the most complex and most common conditions relating to illness and injury. Restoring function to patients who have had surgery, suffered an injury, have chronic pain or are in various forms of recovery are all goals of McLaren’s physical rehabilitation and therapy services. McLaren’s approach to treatment involves many aspects, but strengthening is often a focus for many of their patients. For lower body strengthening, the leg press currently used by McLaren maxes out on using 30% of a person’s body weight for resistance. Once a patient has progressed past that point, the next option is to use full body weight.

Our team has created two possible designs for a brand new Leg Press, both of which are able to bridge the gap between the 30-100% body weight range. The designs constructed focus heavily on keeping the user’s body stationary, thereby easing the process of getting in and out of the device. Delivering McLaren multiple designs allows it to choose the option best suited for its needs. The success of this project will improve the quality of care as well as helping McLaren become more of a presence in sports medicine rehabilitation.

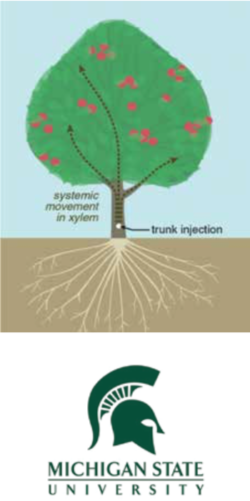

MSU MTRAC: Mechanized Plug Injection System

Trunk injection is an alternative technology for delivering pesticides into fruit trees. Trunk injection eliminates spray drift which results in unintentional coverage, reduces worker exposure, protects natural enemies, and limits the product needed to protect the crop. This technology involves drilling a hole into the tree and injecting a liquid pesticide directly into the xylem. However, this process takes too long to be economically viable for tree fruit and tree nut production. The current trunk injection method that MSU MTRAC created is a solid composite plug and mechanized injector prototype that engages trees singularly, which takes about two minutes per tree. The task is to modify the mechanized injector to function as a tractor- mounted PTO hydraulic unit for high speed orchard use.

One way to combat this limitation and improve efficiency is to design a “magazine” that can hold multiple pods in order to decrease the loading time, and overall injection time. The most efficient method is a mechanical injection system that attaches to a tractor and uses mechanical force to inject the pods, while having a rotating drum magazine for the pods that are controlled by a motor. This decreases loading time as well as having a relatively light injection system that is easily maneuvered between trees. To reduce the time required for each tree, instead of using a single injector, using multiple injectors will be explored in the initial design. This will reduce injection time and could help counteract the force of injection.

MSU Department of Theatre: Theatre Deck Winch

The MSU Theatre Department hosts play productions held at the Wharton Center and is responsible for not only the cast and crew but also the creation of set pieces. These set pieces can weigh up to 3,000 pounds. During a production, these set pieces can be moved either manually or by a deck winch. A deck winch eliminates the need for manual labor and automates the set moving process. Deck winches are widely used throughout the theatre industry. The MSU Theatre Department currently has a deck winch, however it is heavy, cumbersome and horizontal, making it difficult to transport.

The MSU team focused on designing a system that is easier to transport without disassembly. To do this, the team used lighter materials for the frame and designed the winch to operate with a vertical design, as most modern designs are. With a lightweight frame and vertical standing, the winch system can be easily loaded and transported via dolly. Besides the lightweight and vertical design, the winch meets a number of parameters. The winch can pull set pieces at a pace of three feet per second and has a maximum pulling force of 2,500 pounds. To ensure rigidity of the frame, the frame parts are welded together and the system is anchored to the floor via lag bolts.

Fiat Chrysler Automobiles: Seat Bracket

Fiat Chrysler Automobiles, an Italian and American multinational corporation, is one of the largest automakers in the world, with headquarters located in London. Fiat Chrysler Automobiles operations include design, engineering, manufacturing, distribution and sales of automobiles and light commercial vehicles, engines, transmission systems, automotive-related components, metallurgical products, and production systems.

Our team focused on investigating the use of additive manufacturing techniques for car seat brackets to replace the traditional method of manufacturing for a low-volume production. Additive manufacturing includes technologies such as sheet lamination, and directed energy deposition. At the same time, the seat bracket structure is regulated by the global regulatory requirements such as FMVSS, CMVSS, and ECE R17. After considering the cost of each of the additive manufacturing technologies, global regulatory requirements, loadings and material properties, we decided to seek an optimized result that includes the specific low-volume manufacturing method, material, structure optimization and the overall cost that will result in the highest performance and lowest cost and complexity.

Fiat Chrysler Automobiles: Automated Goniometeter

Fiat Chrysler Automobiles is a global supplier of OEM automotive components. FCA’s System and Components EE Lab is tasked with validating the performance of next generation automotive displays. To ensure displays perform at a level that will meet rising customer expectations, extensive testing is done. In direct sunlight many electronic displays will exhibit problems with reflection; thus, it is important to be able to measure reflection accurately.

This project focuses on developing a Goniometer for display and lens material reflection measurement. The goniometer allows the user the ability to position light sources and measurement sensors relative to a DUT (device under test), such as an electronic display or lens. The device allows for rapid and accurate measurements of display and lens reflection at any angle relevant to the position of a display in a vehicle environment. The device is accurate to one degree of arc, allowing repeatable test setup and consistent measurements. The success of this project could have an impact on the quantity and quality of reflection testing at FCA as well as vehicle display end- user satisfaction

National Superconducting Cyclotron Laboratory: LaBr Detector, Half Ball NERO, DSSD Detector

The National Superconducting Cyclotron Laboratory (NSCL) is a national user facility with the mission to allow scientists to make scientific discoveries about the inner workings of atoms and their role in the universe.

The designed decay station, shown on the right, needs to accommodate multiple detector arrays in a flexible and modular system with the ability to measure all possible nuclear decay paths of rare isotopes produced at NSCL. The project design and development of variations to the support frame are to be used in nuclear physics experiments at NSCL. Our project was further divided into three sub-projects.

Project one was the Lanthanum Bromide detector mounting where a mounting system was designed to support LaBr detectors and complete various tasks.

Project two was to create a mounting system, which was designed to suspend the DSSD detector and target mount.

The final project was the half-ball with NERO detector. This allowed access to the inner components of other detectors surrounding the LaBr detectors.

US Environmental Protection Agency: PHEV Smart Charger

The United States Environmental Protection Agency is responsible for setting emission standards for the entire transportation industry. Currently, the EPA is researching ways of documenting and reducing the carbon footprint of electric vehicles. With the facilities currently available, they can accurately track the power draw that EV chargers demand from the power grid. However, in addition, the EPA would also like to test the impact of temperature on power consumption during charging.

Our team was tasked with creating and developing a “smart adaptor” attachment for Level 2 AC high-voltage (HV) charging stations used both indoors and out in the field. The purpose of the device is to record charging data, including voltage and current drawn. It also includes a temperature sensor that measures the outdoor conditions while plugged into the vehicle. The device stores the data on an SD card to be post-processed after the charging is complete. The design of the dongle is low profile, interfaces with all plug-in hybrid vehicles, and supports the weight of the charger while plugged in. It also adheres to the design standards set by SAE document J1772, which outlines the overall function, interface conditions between car and charger, and necessary insulation required for all HV charging equipment. As designed, the charger attachment should allow the EPA to accurately record, log, and compare charging power statistics and weather data during charging.

Heartwood School/Ingham ISD: Therapeutic Mechanical Pony Enhancements

Heartwood School is a center-based school serving students throughout Ingham County. The school assists students ages 3-26 with cognitive and physical impairments and autism spectrum disorders. Heartwood School places an emphasis on its specialized curriculum by incorporating the MOVE program in order to improve the quality of life of affected individuals by allowing them to become more independent through innovative techniques and exercises. One of these is therapeutic horseback riding, which was previously developed by a Mechanical Engineering capstone team in Spring 2017. Therapeutic horseback riding allows the students to develop core and lower back strength, which are crucial for stability and motor control. Having an aesthetically pleasing design allows the students to express their imagination, making it feel less like a routine exercise and more like a horseback ride.

Our team was asked to improve the previous design with structural, storage, and visual upgrades. To improve the structure, the support system was made more rigid, allowing for greater loads. For improving storage, a modular design was implemented, together with improvements for transportability. For visual improvement, the horse was made more realistic with cosmetic upgrades and sound effects. These upgrades allow for a long-lasting design capable of withstanding wear and tear, allowing the students a more realistic and enjoyable therapeutic horseback riding session.

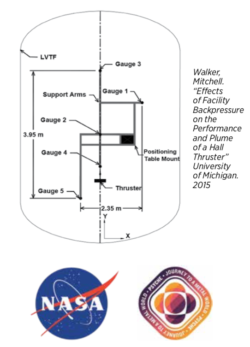

NASA/Arizona State University: Neutral Flux Prob Traversing Mechanism

Psyche is the name of a metal-rich asteroid orbiting the sun between Mars and Jupiter. It is also the name of the NASA mission, led by Arizona State University to visit this asteroid. The spacecraft will launch in 2022 and will utilize solar-electric Hall Effect Thrusters (HETs) in order to reach the asteroid in 2026. A HET is a type of ion thruster that accelerates propellant with electrons in an electric field, then neutralizes these ions as they exit the thruster.

Our team worked in collaboration with an Electrical Engineering capstone team to design and create a neutral flux probe capable of moving throughout the HET test chamber. The ECE group was responsible for creating the neutral flux probe, while our team designed a traversing mechanism that would move the probe around the test chamber. The design of the traversing mechanism had numerous challenges that were overcome throughout the design process. Some of the design constraints are as follows: the weight and dimensions of the neutral flux probe, the dimensions of the test chamber, and the time needed to obtain an accurate test sample. We were able to overcome all of the challenges and constraints and design a traversing mechanism capable of moving the ECE group’s neutral flux probe throughout the test chamber.

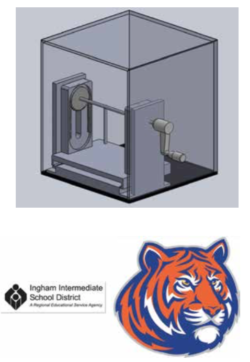

Heartwood School/Ingham ISD: Single Motion Stamp Press

Heartwood School is a local school that services students with moderate to severe cognitive impairments, severe multiple impairments, and autism spectrum disorders. The students attending Heartwood School, from ages 16 through 26, learn skills that center around transitioning to life after school, including cooking, cleaning, money management, and self- determination. One activity that has become popular and has helped with this goal is the process of making and selling cards using rubber stamps. This can be difficult for some students depending on their particular impairment.

Our team was asked to make this process easier and simpler for all students by using a single motion method that incorporates a hand crank similar to a hand-pedal bike. The objectives were met by creating a simple process, including an adjustable crank for students with differing physical impairments, allowing easy portability that doesn’t compromise mobility while in use, and above all ensures the safety of the students at all times.

MSU Baja Racing Team: Custom Brake Calipers & Validation

The MSU Baja Racing Team is an official SAE Collegiate Design Team that designs, builds, and races an off-road vehicle each academic year. The team is student-led and provides an opportunity for engineers to develop hands- on experience in design and manufacturing. The team travels around the country each year to participate in three official Baja SAE competitions where the cars compete in dynamic events and a four-hour endurance race. The cars are also judged on the design, cost, and a sales pitch. To improve overall placement, more custom parts are optimized and validated to bring a better car to competition every year.

Our team focused on the design and implementation of custom brake calipers for the 2019 Baja car. The calipers were designed to provide better braking than the Wilwood PS1 calipers that the team has employed for the past ten years. The calipers were designed to provide enough braking force and prevent any brake fluid leaks that could lead to a loss in pressure. They were manufactured on a Haas CNC using 7075 aluminum to provide a light and strong product. One set of brake calipers was manufactured and assembled on the car. The MSU Baja Team’s engine dynamometer was modified, and an additional caliper was added to perform a full brake study. Data were collected on brake fade along with brake pad and rotor wear. The new calipers and validation will help the team pass brake check and earn it design points at the competitions this year.

MSU Entomology: Quick Connection System for Solid Set Canopy Delivery System

The solid set canopy delivery system (SSCDS) is a distributed network of micro-sprayers in fruit crop canopies that are fed by a pumping system that is located outside of orchards. This system has been created to help farmers across the world reduce drift and waste, limit exposure to the chemicals, and reduce labor. Unlike the conventional tractor-based system, this system helps create a safer working environment and protect surrounding crops and environments.

To improve the current SSCDS, our team was asked to develop an integrated quick connect system. This connector will make it easier for the pumping system to be attached to the sprayers and will be capable of withstanding the application and environmental conditions which are present in an orchard.

The connector will have a male part that will always be attached to the pump’s tubing and a female part attached to the tubing out in the field. This connector will need to be a slip coupling that is both water and airtight. The connector also needs to be able to dry lock. These three requirements are the most important in designing the coupling because together they provide the safest connector for the user and the environment.

Salt Yoga: Yoga Tone Yoga Belt

Toni Thomas, the owner of Salt Yoga in East Lansing, Michigan, is looking to revolutionize the yoga industry. The grand opening of her studio is this Spring 2019, and she is looking for ways to bring in new customers and challenge her existing clients. Her studio offers a certain brand of hot yoga that involves halo therapy. Halo therapy is a dry salt therapy that aids in general wellness by removing toxicity from the respiratory system while also invigorating the body with increased lung capacity and oxygen intake. She conceived of the Yoga Tone Yoga Belt to add resistance and increase the challenge of a typical salt yoga session.

Our design team brought the idea to fruition and developed the prototype starting from the customer needs identified by Ms. Thomas. The team identified materials that were compatible with the hot yoga environment, which can be warmer than 90 °F with high humidity. The team used biomechanical analysis to determine the resistance bands needed. The fixture points and attachment methods were developed empirically. The result should be compatible with a variety of body sizes and abilities of the yoga practitioners. Our team designed the belt to integrate smoothly into the workout without inhibiting required motions or causing discomfort at the attachment points. The design incorporated a modular philosophy so that the bands, belt, and wrist and ankle straps can be cleaned or replaced as required.

MSU Department of Theatre: Revolving Stage Turntable

The Michigan State University Department of Theatre offers MSU students many academic courses and degree programs from acting to production design. The department also produces a wide range of different theatrical productions every season and often designs and builds its own sets for the shows.

The department is interested in having a large revolving turntable stage piece designed. The turntable would be driven by a friction drive motor and be variable in size from 12 to 24 feet in diameter with 6-foot increments. The surface of the turntable must allow for the customizable attachment of sets anywhere on its surface. In addition, the entire assembly must be simple and lightweight enough for two people to assemble in a few hours using few tools. The Department of Theatre requires the ability to run electrical power from the stage to the turntable to allow for set lighting. The turntable must be able to rotate at a maximum rate of 30 degrees per second angular speed and a minimum rate of 1 degree per second.

This lightweight adjustable turntable stage piece will expand the capabilities of the MSU Department of Theatre and allow for many interesting and versatile stage designs. The Departments of Mechanical Engineering and Theatre will both benefit from a closer relationship encouraging future collaboration.

McLaren Greater Lansing: Rehabilitation Gym Adjustable Car

McLaren Greater Lansing is the leader in hospital, medical, and healthcare for Lansing and surrounding areas. McLaren’s services include patient rehabilitation centers for cardiology, pulmonary, sports medicine, and physical and occupational therapy. Physical and occupational therapy are critical for patients who have undergone total knee replacement or total hip replacement to adjust to everyday life with new limitations. A new McLaren hospital facility is in the process of being built adjacent to Michigan State University and is slated to open in 2021.

Our team designed a rehabilitation car for patients undergoing occupational therapy at McLaren Hospital. The car will emulate a realistic car environment in which patients can practice safe transfers while remaining in the hospital. To accommodate the variety of vehicles used by rehabilitation patients, the car will be height-adjustable and include a retractable running board. This project will aid in the transition from therapy to everyday life for patients in the rehabilitation gym of the new McLaren facility.

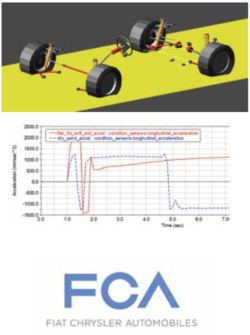

Fiat Chrysler Automobiles: Multi-Body Simulation of Tire/Soft Soil Interface

Fiat Chrysler Automobiles (FCA) designs, engineers, manufactures, and sells vehicles and related parts and services, components, and production systems worldwide through 159 manufacturing facilities, 87 R&D centers, and dealers and distributors in more than 140 countries. Its brands include Abarth, Alfa Romeo, Chrysler, Dodge, Fiat, Fiat Professional, Jeep, Lancia, Ram, Maserati, and Mopar – the parts and service brand.

Our team focused on construction of a full-vehicle multi-body simulation model, in particular to understand the behavior of an interface between a vehicle tire and a soft sand/loose soil road profile. Tire parameters, including normal tire load, vertical stiffness, damping, and rolling resistance were considered. In addition, various vehicle maneuvers within straight-line and open-loop steering events were used as testing maneuvers in the simulation. Such simulation and vehicle dynamics studies were completed with ADAMS/Car provided by MSC Software. The project primarily focused on using multi- body simulation software rather than other conventional Finite Element Method-based simulation software on tire and soil interface analysis. This offers simplicity and new insight into vehicle dynamics analysis on off-road simulations.

MSU Recycling Center: Automated Recycling Collection

Environmental sustainability is the ability to meet the needs of present and future generations. The Michigan State University Recycling Center is responsible for helping MSU become an environmentally sustainable campus. The primary responsibility of the recycling center is to maintain the recycling bins around MSU. Currently, there are 200 recycling bins set up throughout campus. During football season, the number of bins increases to 800. Managing all of these bins can be challenging.

Twice weekly, a two-person team travels to monitor all of the bins. During these travels, most of the bins are found to be less than 50% full and do not need emptying. This results in multiple costs: increased labor, increased required materials, and increased carbon dioxide emissions are a few examples.

Continuing last semester’s project, our team focused on designing and creating a device that could measure the fullness of each recycling bin and send the results to a database each morning for analysis. Because there is a surplus of recycling on home football game days, our team also focused on each device having the ability to be programmed in order to alter minor issues such as how many times the fullness is read, change of location, and GPS tracking. The success of this project will save the university money and resources, as well as help to make campus run more efficiently.

Gerdau Special Steel North America: Heat Treat Furnace Rolls

Gerdau Special Steel North America is an engineered bar producer headquartered in Jackson, Michigan with world-class steel manufacturing mills in Jackson, Michigan, Monroe, Michigan, and Fort Smith, Arkansas, as well as metal processing facilities in Huntington, Indiana. Gerdau steel mills takes 100% scrap steel, and melts, casts, and rolls it into round bars. Those bars are then sent through value added processing, including heat treatment, straightening, peeling, and non- destructive testing for internal and surface quality. Due to the large number of orders processed by Gerdau Special Steel North America, roll breakdowns and maintenance have detrimental effects upon order processing time and expected furnace life.

Our team was asked to investigate both material and design factors with respect to roll breaks in Gerdau’s STC batch furnaces and to recommend changes to either design, material, or both, that will result in fewer breaks and longer operational life. Our team utilized Altair Inspire and ANSYS Finite Element Analysis (FEA) programs in conjunction with a material study of failed rolls to investigate the current design and to provide proposed solutions. Solutions were classified as minimal, moderate, or significant in scope to facilitate decision-making and implementation in a dynamic business environment.

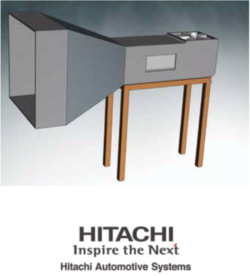

Hitachi Automotive Systems Americas Inc.: Tabletop Wind Tunnel

Hitachi Automotive Systems Americas Inc. (HIAMS) is a Tier 1 supplier of global automotive products. HIAMS manufactures and markets OE products such as engine management systems, electric powertrain systems, and drive control systems. When designing and developing electronic control units (ECUs) for the automotive industry, Hitachi must verify that the controller has the ability to reject thermal energy from the electronics to the ambient environment. Hitachi needed a method to validate the performance of prototype designs during the early development phase.

Our team was tasked with building and testing a reliable and affordable tabletop wind tunnel for ECUs. The solution requires variable control of airflow volumetric flow rate, air temperature, and a 12x12x6 test chamber. We successfully created a tabletop wind tunnel that validates the performance of laminar flow across airflow range, airflow volume and temperature in the test chamber. The solutions include instruction for use, calibration, CAD assembly, and a final BOM.

Whirlpool Corporation: Small Space Dryer

Whirlpool Corporation, headquartered in Benton Harbor, Michigan, is the world’s leading major home appliance company. Whirlpool markets products worldwide, with approximately $21 billion in annual sales, and 92,000 employees across 65 manufacturing and research facilities. The company’s global impact, combined with a commitment to innovative, sustainable and affordable solutions creates a potential for large markets and a wide range of products. The goal is not only designing for functionality but delivering an experience. While many clothes drying options are already available – ranging from storable drying racks to conventional tumble dryers – there is need for a mid-level solution that combines functionality and efficiency with usability and a positive experience.

Our team was tasked with developing a product to meet this tailored market. After defining the primary design intent and problem constraints, a systematic process was implemented to establish and compare potential solutions. Factors such as the intended customer audience and system primary functions were identified. Technical documents, such as concept selection matrices (CSM), tradeoff diagrams, and P-diagrams, aided in organizing and tracking development progress. With the frontend development completed, next steps can be taken to prototype and test the most promising solutions.

TERPHANE: New Packaging Design Development

TERPHANE is a company that designs and manufactures polyester products, such as heat sensitive films, in North and South America. The combination of TERPHANE polymer formulations and additives with a co-extrusion and stretching process, together with other special treatments (coatings, corona treatment, metallization), is designed to meet the demanding packaging and industrial needs of its customers. Since the addition of its new state-of-the-art P3 line in Brazil, TERPHANE currently produces over 38,000 tons of product per year. TERPHANE’s plant in Brazil is the only bi-oriented polyester film producer in South America, providing a full line of advanced polyester films and specialty products.

In recent years, there has been a growing demand for food deliveriy services However, in many cases, food may become cold or contaminated during transport due to long delivery times or poor handling practices. For example, it can take more than an hour to deliver food to some restaurants. The food sometimes arrives in various conditions after it has left the kitchen. Our team has been asked to design a disposable delivery box that is fully sealable, low-cost, and easy to manufacture. The design will help people get better quality takeout food. In addition, we designed and developed a prototype machine to automate the construction of the food container.