Electrical Engineering

Projects

Electrical and Computer Engineering ECE 480 Senior Design is required of all electrical and computer engineering majors at MSU.

For information on becoming a project sponsor, please contact Gregg Motter.

The following are the project sponsors and projects for the spring of 2014:

Fitness Metrics, LLC: Sensor Technology Interface

Sensors are becoming more prevalent in our everyday lives. These sensors’ protocols can vary drastically, such as being wired, wireless, analog, or digital. One consequence of this is that viewing the data from all of these sensors at once is inconvenient.

Sensors are becoming more prevalent in our everyday lives. These sensors’ protocols can vary drastically, such as being wired, wireless, analog, or digital. One consequence of this is that viewing the data from all of these sensors at once is inconvenient.

An elegant solution to this problem is to consolidate the information from these sensors onto one platform, which can then display all of the sensors’ data in one UI. This platform consists of two components: a sensor interface (SI) to receive the sensor information, and an Android app to display the information to the user.

The SI is capable of receiving information from both wired and wireless sensors. It can also store up to 1 hour of this sensor input on an SD card. Finally, when it is connected to an Android device via Bluetooth, the SI transmits the sensor data to the app.

The Android app has several features. It lists all of the sensors that are being monitored, along with their current reading. It also allows the user to add new sensors to display. Furthermore, the app can display a graphical history of a sensor’s readings.

This platform will provide users with a convenient way to read the sensors all around them. Now, they can have all of this information in the palm of their hand.

MSU Department of ECE: Test-bed Development for Geo-location of RF Emitter

The ability to accurately detect the location of radio signals provides a wide variety of uses ranging from determining the location of a distress signal from a party or individual in need of help to locating an interfering signal that is jamming communications.

The ability to accurately detect the location of radio signals provides a wide variety of uses ranging from determining the location of a distress signal from a party or individual in need of help to locating an interfering signal that is jamming communications.

A relatively new technology known as Software Controlled Radios now exists which gives the user a wide range of options and tools for receiving radio signals. With a small, lightweight interface unit, known as a Universal Software Radio Peripheral (USRP), coupled with GPS data and a computer, one has the ability to dynamically receive a wide range of radio signals. By using software scripts to extract information from these signals, RF signal information is put into a database file. These data files can then be queried by scripts and numerical analysis software, such as IPython, to create RF signal strength diagrams and maps for a particular area.

Our project creates a test-bed which is fully functional; the field unit can operate on a battery and send gathered RF signal information back to a host computer using Wi- Fi technology. Further, we demonstrate how the radio software can be used to create helpful information in a user interface, such as: time of measurement, GPS coordinates of the antenna and strength, and approximate direction of the signal. This system will serve as a test-bed for researchers, such as the Military, to write more sophisticated algorithms to use on the captured database intelligence to a more advanced degree.

ECE Shop: Ballistic Chronograph

Ballistic Chronographs are used to measure the velocity of projectiles. Our chronograph is designed to assess the projectile mid-flight.

Ballistic Chronographs are used to measure the velocity of projectiles. Our chronograph is designed to assess the projectile mid-flight.

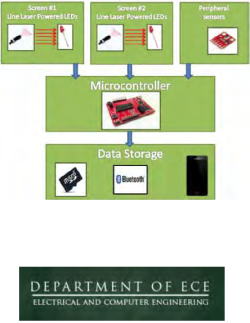

Our design incorporates two 14 inch x 14 inch square screens, creating a large detection area for the users’ convenience. Each screen consists of two line lasers and two banks of reverse-biased LEDs, creating a virtual sensing plane. When projectiles cross each screen, the line lasers are interrupted and a microcontroller detects the change in voltage across the LEDs. The most common implementation for screens use infrared sensors to do projectile detection. While infrared sensors are a working option, they are often unreliable due to changing light conditions that cause the readings to be inaccurate. Part of the project description was to investigate alternatives to infrared sensors, and explore a line laser detection scheme.

Environmental factors can influence projectile velocity. Our design will incorporate peripheral sensors to record factors such as atmospheric pressure, altitude, humidity, and temperature. These factors, as well as the projectile velocity can be displayed on an LCD screen.

Additionally, the chronograph will be saving every data set displayed on the LCD to an SD card. For convenience, all data from the chronograph will be reported back to the user over Bluetooth to an Android application where the user can monitor or save the information.

Team Members (L-R): Nicholas Mancuso, James Cracchiolo, Xuming Zhang, Madi Kassymbekov, Steve Kanitz

General Motors: Rapid Prototyping Environment: Climate Control

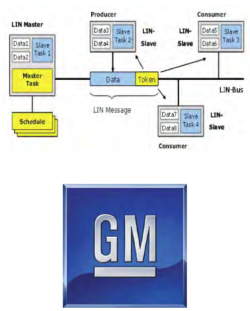

During the development of a climate control system in a vehicle, Rapid Control Prototyping (RCP) must be done in order to ensure that the optimal design is chosen. Accomplishing this is a timely task, so software is used to virtually design the system for the ease of modifying parameters in the developmental stage thus saving time and money. Due to the benefits that RCP offers, General Motors is focusing their resources into developing an RCP climate control system through the software dSPACE. This software allows for the virtual design of an Electrical Control Unit (ECU) for the handling of a real time signal communicated through a Local Interconnect Network (LIN) which then controls actuators and sensors to modulate and detect the lighting and temperature in an automobile.

During the development of a climate control system in a vehicle, Rapid Control Prototyping (RCP) must be done in order to ensure that the optimal design is chosen. Accomplishing this is a timely task, so software is used to virtually design the system for the ease of modifying parameters in the developmental stage thus saving time and money. Due to the benefits that RCP offers, General Motors is focusing their resources into developing an RCP climate control system through the software dSPACE. This software allows for the virtual design of an Electrical Control Unit (ECU) for the handling of a real time signal communicated through a Local Interconnect Network (LIN) which then controls actuators and sensors to modulate and detect the lighting and temperature in an automobile.

With the requirements for signal systems increasing, analog data transfer techniques are showing their limitations. LIN permits General Motors to transition from analog to digital communication which allows for the advanced processing of signals sent from the ECU and delivered to the actuators and sensors. This system is represented in the figure to the right with the ECU represented as the LIN Master and the actuators and sensors represented as the LIN Slaves.

After designing, implementing and testing the RCP climate control environment, the system will provide greater accuracy and control of LIN based actuators and sensors to modulate temperature, save on wiring costs, and offer the ability for real-time correction during signal acquisition.

MSU Resource Center for Persons with Disabilities: Refreshable 3D Braille Display

In an age of forever increasing digitization, issues arise with equalizing opportunities for the blind. As universities push for the adoption of new technologies such as braille printers, blind students may be left behind other students. This presents a lack of resources for blind students, especially when it comes to situations which require 3D images (e.g. 3D curves in calculus, maps, etc.). Currently, there are no existing devices that utilize a refreshable display in order to display 3D images.

In an age of forever increasing digitization, issues arise with equalizing opportunities for the blind. As universities push for the adoption of new technologies such as braille printers, blind students may be left behind other students. This presents a lack of resources for blind students, especially when it comes to situations which require 3D images (e.g. 3D curves in calculus, maps, etc.). Currently, there are no existing devices that utilize a refreshable display in order to display 3D images.

Team 5 will construct a device that will be able to receive image files, analyze and process the image in terms of color intensity, and then output these results via a 3D pin matrix display, with color intensity determining the height of each pin.

The device will feature a 64×64 pin matrix display that will be adjustable from zero to one inch. This resolution was picked so that users will be able to utilize their entire hands to feel the image, creating a more immersive experience. The pins will be held captive by independent grooved panels and will be set by a servo which moves along rails for XY axes motion. The servo will have a mechanism to convert rotational motion to Z axis motion, which will set pins to the desired height. Pins will then be “locked” into place by increasing pressure on the pins. This will all be controlled by an Arduino microcontroller.

The refreshable nature of this device means that the device has numerous practical applications with functionality that is currently unavailable in the marketplace. It will also be far less costly than the use of non-refreshable technology.

MSU Resource Center for Persons with Disabilities: Bluetooth Low Energy Beacon

The Michigan State University campus in East Lansing consists of 538 buildings spread out over 8.125 square miles. For the blind or visually-impaired members of the Michigan State community, navigating campus can be a challenging task. The Resource Center for Persons with Disabilities at Michigan State University has proposed to use a new interactive positioning interface, a Bluetooth Low Energy (BLE) beacon to assist blind people in navigating around campus.

The Michigan State University campus in East Lansing consists of 538 buildings spread out over 8.125 square miles. For the blind or visually-impaired members of the Michigan State community, navigating campus can be a challenging task. The Resource Center for Persons with Disabilities at Michigan State University has proposed to use a new interactive positioning interface, a Bluetooth Low Energy (BLE) beacon to assist blind people in navigating around campus.

With the release of iOS 7, Apple announced iBeacons, a feature that allows an iOS device to calculate its location relative to Bluetooth beacons. The MSU RCPD is looking to utilize this technology for assistive navigation by placing Bluetooth Low Energy (BLE) beacons inside building entrances and hallways. These beacons will allow iOS 7 and Android based smart phones to precisely calculate their position inside a building.

This project’s focus is to develop a low-cost Bluetooth Low Energy beacon compatible with Apple’s iBeacon technology. The beacons broadcast a unique identifier allowing the receiver to triangulate its position based on the known locations of the beacons. Bluetooth Low Energy-enabled Android and iOS devices will be able to detect the beacons, calculate distance from the beacons based on the received signal strength, and display notifications and navigation information based on their location. Text-to-speech functionality built into both iOS and Android is used to read the navigation information aloud.

MSU Solar Car Team: Battery Management System

Our design team is tasked to build a battery management system for the Michigan State University Solar Car Team. The Solar Car team is one of the newest racing teams at Michigan State. In the past years the solar car has had issues with many components. A way to improve the car is to create a customizable battery management system.

Our design team is tasked to build a battery management system for the Michigan State University Solar Car Team. The Solar Car team is one of the newest racing teams at Michigan State. In the past years the solar car has had issues with many components. A way to improve the car is to create a customizable battery management system.

A battery management system (BMS) is an electronically controlled system that manages rechargeable battery cells. The system protects the battery cells by monitoring the voltage, the current, and the temperature of the battery cells. When any of these measurements falls outside the specified design limits, the BMS will take corrective actions to ensure system stability and safety. The basic design of our system can be seen modeled in CAD on the right.

A customized battery management system is one of the most important aspects of a solar car. Batteries contain a large amount of energy, and any sort of problem with the batteries can have disastrous consequences. Problems with the voltage, current, and temperature of the batteries can destroy the batteries and need to be controlled in order to be safe. By using sensors, battery balancing, and an emergency cut-off switch, the driver of the car can be sure that any problems will be handled properly, and that the battery packs will be safe from any failures.

Team Members (L-R): Gerald Saumier, Matthew Gilbert-Eyres, Michael Burch, Auez Ryskhanov, Albert Ware

MSU Resource Center for Persons with Disabilities: Accessible Tactile Graphic Printer

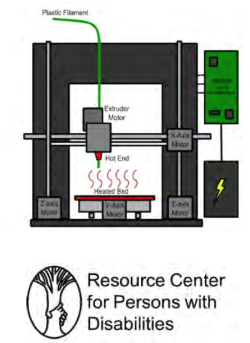

Tactile graphics and Braille are essential components to making education accessible to the visually impaired. The Resource Center for Persons with Disabilities (RCPD) on MSU’s campus currently preserves two tactile graphic embossers that produce pictures, charts and drawings to assist blind students in their studies. The downfall to these embossers however, is that the images that it produces are quite frail and are eventually pressed down after repeated use, which in turn makes it difficult for a blind student to identify the image. Thus, the team was assigned the responsibility of designing a specialty printer that can be used to produce tactile graphics and maps for blind users/students at MSU. If successful, a duplicate design will be created for a school for the blind in India. This designed tactile graphic printer should produce more durable images and cost significantly less.

Tactile graphics and Braille are essential components to making education accessible to the visually impaired. The Resource Center for Persons with Disabilities (RCPD) on MSU’s campus currently preserves two tactile graphic embossers that produce pictures, charts and drawings to assist blind students in their studies. The downfall to these embossers however, is that the images that it produces are quite frail and are eventually pressed down after repeated use, which in turn makes it difficult for a blind student to identify the image. Thus, the team was assigned the responsibility of designing a specialty printer that can be used to produce tactile graphics and maps for blind users/students at MSU. If successful, a duplicate design will be created for a school for the blind in India. This designed tactile graphic printer should produce more durable images and cost significantly less.

Stephen Blosser of the RCPD, along with the team, proposed the idea of designing a 3D printer in order to address these concerns. The image will be created using a Computer- Aided Design program (CAD) and then saving this file as a StereoLithography (STL) file. This file will be transferred to a g-code generator program such as slic3r which will convert the file into a set of instructions that the printer will understand. This 3D printer will consist of a heatbed and an extruder which will extrude a filament onto an 11×17 inch glass surface, one layer after the other, creating the required image. Once the printing process is finished, the heated surface begins to cool down and the figure is available for detachment.

Team Members (L-R): Maram Sulimani, Caroline Kerbells, Martez Steverson, Bryan Cotton, Eman Aljabr,, Changqing Yang

Robert Bosch, LLC: Navigation and Infotainment System Monitor

Have you ever wondered how the GPS system in your car works? The process for developing such a system takes countless hours of testing and debugging. In order to make this process easier, we are developing a monitoring system to record bugs while testing these systems.

Have you ever wondered how the GPS system in your car works? The process for developing such a system takes countless hours of testing and debugging. In order to make this process easier, we are developing a monitoring system to record bugs while testing these systems.

This system developed at Bosch’s Automobile department is aimed to record videos during the driving test without disturbing driver’s attention. It is not a simple machine anymore, but a system that combines the video recorder, computer processor, and a data storage system; which can support hot plug and play. The goal of this system is to provide a safe and reliable error recording system for test drivers, ensuring all entertainment and navigation functions operate successfully, and further improving the system. The system must properly work in variable situations, like short travel on a snowy day or crossing multiple states. It also has to record all the errors about software bugs or misuse.

In this project, the design team will improve the original system, and provide a video monitor for the testing driver. The video monitor will show the four camera angles, timestamp, GPS coordinates, and memory left in storage. The possible solution that the design team wants to fulfill is to combine 4 cameras’ input into a central microcontroller. The microcontroller will store all video recording into either a USB drive or SD card. When an error occurs, the tester presses a switch, and then the microcontroller generates a video from the last five minutes.

Robert Bosch, LLC: iOS Application for Test Drive Error Reports

Bosch is well-known in industry for researching and developing in-car information systems. The company was awarded the “Best-of-CES Award 2013” at the Consumer Electronics Show for the Chevrolet My Link System.

Bosch is well-known in industry for researching and developing in-car information systems. The company was awarded the “Best-of-CES Award 2013” at the Consumer Electronics Show for the Chevrolet My Link System.

In order to maintain the elite status of its infotainment systems, Bosch must constantly run diagnostic tests in order to debug and update its software.

To assist Bosch with recording error reports during automobile test drives, we have been enlisted to develop a mobile application for testing.

The key objective is to create a virtually hands-free iOS application that captures a structured speech input, logs all information, then outputs an Excel file. The application will collect failure information from the user by prompting questions, such as, “What component has failed?” The application will then record and transcribe the response using voice recognition software.

At the end of the test drive, the user will be able to edit the data. All data will be exported into a .CSV file and submitted via email from inside the app.

The final application will be written in Objective-c Coding using Xcode Software. AVSpeechSynthesizer Software will be used for voice prompts. The application will function on both Apple iPhone and iPad devices.

Team Members (L-R): Ryan Bilton, Feifei Li, Mark Mudro, Kaichang Wang, Charlton Washington, Kyler Wilkins

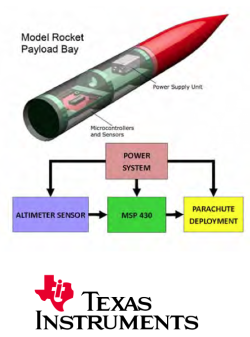

Texas Instruments: Electronic Parachute Deployment System

Model rocketry is a popular hobby enjoyed among several age groups. One essential component includes the ability to deploy parachutes for a safe landing and reuse of the rocket. This project presents the opportunity to evaluate and develop a multistage Electronic Parachute Deployment (EPD) system for large-scale model rockets.

Model rocketry is a popular hobby enjoyed among several age groups. One essential component includes the ability to deploy parachutes for a safe landing and reuse of the rocket. This project presents the opportunity to evaluate and develop a multistage Electronic Parachute Deployment (EPD) system for large-scale model rockets.

The primary function of the EPD system is to activate the parachute deployment process. Once the rocket reaches the apogee, the EPD system will initiate the return of the rocket to the ground by deploying the drogue chute. At a secondary point the EPD system will deploy a second parachute to reduce the impact force upon landing.

The EPD system consists of a sensor, microcontroller, and power supply unit. The sensor used is an altimeter to measure the altitude of the rocket based on absolute atmospheric pressure. The altimeter outputs the signal to a MSP430 microcontroller that detects the descent. The power supply demonstrates the capability to power the ignition fuse while also powering the other components.

The team designed, simulated, and fabricated each subsystem through creating a Printed Circuit Board (PCB) that incorporates all of the EPD system functionalities. The design of the PCB meets the physical constraints of the payload bay. The final solution allows for a flexible EPD system that can be used through various model rockets.

Team Members (L-R): Michikazu Aono, Qiaosen Huang, Pedro Rodriguez, Max Cooper, Zane Crawford, Jessica Shelby

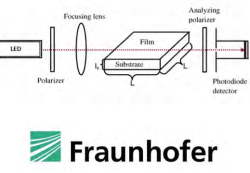

Fraunhofer Center for Coatings/Laser Applications: Diamond Optical Properties Measurement System

The Fraunhofer Center for Coatings and Laser Applications is responsible for growing synthetic diamonds. Diamond is a material with extreme properties including highest hardness, very chemically inert, highest thermal conductivity and has a wide spectral window for transmission of light. Therefore, it is very important that these artificially-grown diamonds are grown with as little impurities as possible.

The Fraunhofer Center for Coatings and Laser Applications is responsible for growing synthetic diamonds. Diamond is a material with extreme properties including highest hardness, very chemically inert, highest thermal conductivity and has a wide spectral window for transmission of light. Therefore, it is very important that these artificially-grown diamonds are grown with as little impurities as possible.

One of the more sensitive measurements of the quality of diamond is birefringence. Birefringence is an optical quality where linearly polarized light shining through a flat diamond piece is made non-polarized by imperfections in the diamond. The goal of this project is to develop a birefringence measurement system.

The proposed solution is to design a system where a linearly polarized LED shines through a diamond flat sample with the light exiting the diamond being filtered by a linear polarized filter. This will transmit only the light polarized 90 degrees with respect to the input light. The presence of defects and stress in the diamond causes the polarized light to exit the diamond partially non-polarized, and it is the strength of the non-polarized light that is to be measured. This system will meaure the light intensity of each pixel, calculate the birefringence, and display a quantifiable 2-D map.

This project will ultimately help Fraunhofer share their data related to diamond impurities in an effective and efficient manner.