Applied Engineering

Projects

We gratefully acknowledge Jim Manely and the Demmer Center for Business Transformation at Michigan State University for their guidance and assistance with our projects. We gratefully acknowledge Judy S. Jacobs, Director, Corporate & Student Relations Office, Michigan State University, Department of Supply Chain Management for her assistance in securing projects.

For information on becoming a project sponsor, please contact Dr. Laura Genik.

The Applied Engineering Sciences Capstone class is held in Spring Term only. The following were the project sponsors and projects for the Spring of 2014:

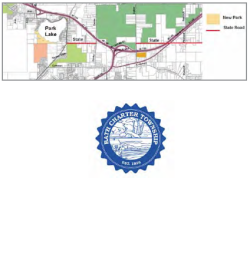

Bath Township: Road Extension-An Enabler for Bath Township

Bath Township is located just northeast of East Lansing and is currently seeking support in assessing the possibility of extending State Road through its township. State Road currently stops and starts as it runs east to west through Bath. State Road dead ends at Chandler Road, the Bath Township western border, making travel from the west difficult. Bath is also developing a park at the south end of Park Lake and a road or non-motorized trail would benefit access to the future park.

This project would provide a non-motorized trail or road connecting much of Bath’s population to East Lansing’s trail system which in turn connects to Lansing’s River Trail system. Most of the extension would actually run across City of East Lansing property because the city annexed about 1,000 acres during the 1990s so any development will require involvement from both jurisdictions.

This project would provide a non-motorized trail or road connecting much of Bath’s population to East Lansing’s trail system which in turn connects to Lansing’s River Trail system. Most of the extension would actually run across City of East Lansing property because the city annexed about 1,000 acres during the 1990s so any development will require involvement from both jurisdictions.

This project touches on several important issues. Areas addressed include economic development issues (bringing people to Bath, improving quality of life in Bath), recreational issues (a non-motorized path linking Bath’s future park to a large trail system would benefit Bath residents and the region) and political issues (both Bath Township and the City of East Lansing would have to work together and agree on the plan).

Team Members: Joe Frustaci, Aaron Klein, Lucas Sproul, Ben Caneba, Tevyn Gentile Project Mentor: Kalpana Prabhu

Habitat For Humanity: Redesigning MRDC Basic Operating Premise

With over 50 restores spread across the state of MI, Habitat for Humanity faces challenges trying to distribute shipments in a cost-effective and efficient manner to stores where needed. The Michigan ReStore Distribution Centers (MRDC) is the solution Habitat has come up with. MRDC has been operating for 4 years.

The purpose of the MRDC is to help Habitat for Humanity handle and distribute large donation shipments for the restores. Currently companies will donate multiple semi truckloads of one material such as doors or windows. No restore is large enough to handle and sell one whole truckload of a single material. So the companies ship the material to the MRDC, which then notifies stores, and they come and pick up however much they need. This makes it easier for companies to donate to Habitat, because they always have a place to ship to. Also it makes it easier for the restores, because they don’t

The purpose of the MRDC is to help Habitat for Humanity handle and distribute large donation shipments for the restores. Currently companies will donate multiple semi truckloads of one material such as doors or windows. No restore is large enough to handle and sell one whole truckload of a single material. So the companies ship the material to the MRDC, which then notifies stores, and they come and pick up however much they need. This makes it easier for companies to donate to Habitat, because they always have a place to ship to. Also it makes it easier for the restores, because they don’t

have to handle such large inventory.

The MRDCs are running full and have no budget to expand. Also they can’t afford commercial shipping to move inventory between MRDC locations.

Objectives

• Decide if MRDCs are feasible to keep

• Maximize floor space in MRDC

• Find a cost-effective way to move inventory

• Make it easier for Restores to pick what they need

Team Members: Autumn Vassell, Stephanie Seibert, Micqueal Harris, Adam Dabkowski, Andrew Goins Project Mentor: Kalpana Prabhu

MSU Office of Sustainability: MSU Sustainability Eco Rep Program

Michigan State University is among the most sustainable universities in the nation and continues to improve sustainable practices. Among the many people influencing these processes are the Eco Representatives. MSU’s center of excellence for disseminating sustainability information across the university depends on the Eco Rep program. The Eco Rep program at MSU consists of a coordinated group of 381 faculty and staff representatives that promote environmentally friendly practices within their department to push MSU towards 100% renewable energy. However, there are currently no students involved in the program.

Our intent is to develop a student Eco Rep program based on the current staff and faculty program’s core competencies. The project scope is to determine the awareness and interest of students in regards to “being Spartan green” and develop a plan for incorporating the student body.

Our intent is to develop a student Eco Rep program based on the current staff and faculty program’s core competencies. The project scope is to determine the awareness and interest of students in regards to “being Spartan green” and develop a plan for incorporating the student body.

Collaboration with the MSU Sustainability Office will help in the adaptation of our recommendations that we provide them for establishing a student Eco Rep program. Our contacts there provide us with information pertaining to the current program in place, and what they would like to see going forward. A recommendation will be delivered to our sponsor, based on the feedback received for students’ interest in the program. The recommendation will provide a structure in establishing a student-driven Eco Rep program. We plan to use this knowledge for further application of sustainable practices.

Team Members (left to right): Chad Gierak, Eric Mathes, Keri Keinath, Brad Kittel, Claire Veit Project Mentor: Zach Tomlinson

MSU Office of Sustainability: MSU Sustainable Incentive Plan

Michigan State University has been recognized as one of the most sustainable universities in the nation. In April 2012, an Energy Transition Plan was approved by the Board of Trustees which was designed to guide the university towards being powered by 100 percent renewable energy.

The Energy Transition Plan (ETP) has set goals and targets that look to balance important variables such as capacity, cost, environment, and reliability. A key component to the implementation of the ETP is the development of a sound financial and/or social incentive program. The incentive program looks to motivate decision-making units at department levels across campus to implement energy conservation recommendations.

The Energy Transition Plan (ETP) has set goals and targets that look to balance important variables such as capacity, cost, environment, and reliability. A key component to the implementation of the ETP is the development of a sound financial and/or social incentive program. The incentive program looks to motivate decision-making units at department levels across campus to implement energy conservation recommendations.

Our group looks to thoroughly review the university’s current energy conservation incentive program and document its present strengths and weaknesses. We are also reaching out to other universities to review and compare the benefits and drawbacks of systems that they are utilizing. Additionally, we will be contacting corporate organizations to see what energy conservation techniques and incentives are being implemented throughout various industries.

Interviews with MSU students, faculty, and professors will also provide us insight into how aware people are of the ETP, and what practices may have the largest impact on the MSU community. Upon completion of our intensive research, we will be delivering an outline of best practices and potential recommendations for the University’s consideration.

Team Members (left to right): Drew Lied, Larry Turnbow, Katie Conely, Stephen Riedy, Trevor Patterson Project Mentor: Zach Tomlinson

Michigan Biotechnology Institute: Value Chain for Thermo-Polyurethane Foam

MBI is a service based company assisting its clients in the commercialization of renewable products. Their laboratories and technical staff are available to accelerate the development and scaling of bio-based technologies. Currently, a division in MBI is developing a renewable foam product with the help of Dr. Narayan. This new foam could replace existing foam products in cars, furniture, and bed mattresses.

The assigned project is to conduct research on the value chain of furniture and automotive seat manufacturers. The chain will be focused around current thermo polyurethane foams the manufacturers are using. Once the value chain has been established, a cost analysis of the current foam will be conducted. With the cost analysis complete, the team will compare the difference between using a bio-renewable foam versus current standards.

The assigned project is to conduct research on the value chain of furniture and automotive seat manufacturers. The chain will be focused around current thermo polyurethane foams the manufacturers are using. Once the value chain has been established, a cost analysis of the current foam will be conducted. With the cost analysis complete, the team will compare the difference between using a bio-renewable foam versus current standards.

This information can assist MBI in penetrating markets rich with opportunity. The advantage of these Biodegradable TPUs as they are referred to is reducing the carbon footprint left by many companies. At the end of a product’s life cycle instead of being considered “toxic” in a landfill, it will biodegrade and return the carbon back to the environment, essentially reducing the carbon footprint left by the company and helping diminish the effects of global warming in the longterm. By finding the costs of other TPUs we will be able to have a target price for the biodegradable TPU. This knowledge will help Dr. Narayan make marketing decisions to get this product in as many possible different markets.

Team Members (left to right): Jonathan Elkins, Ryan Jeffery, Brendan Muir, Jimmy Feiten, Bradford Wallis Project Mentor: Kalpana Prabhu

XG Sciences: Applications of Graphene Nanoplatelets as a Heat Spreader

XG Sciences Inc., founded in 2006, is a privately owned company headquartered in Lansing, MI. The company was formed to manufacture and sell large quantities of a material called XGnP Graphene Nanoplatelets using a cost-effective and unique manufacturing process pioneered by the Drzal research group at Michigan State University. XGnP Graphene Nanoplatelets exhibit many desirable thermal and electrical properties that make it a very competitive material. By 2010, XG Sciences achieved its quality goals to release the first commercial line of nanoplatelets called Grade H, with subsequent grades being released since then.

Team XG Sciences, through in-depth market analysis and implementation of effective business strategies, will provide a summary analyzing the practical applications of XGnP Nanoplatelets as a heat spreader in electronics. Our team will research current heat spreader technologies, identify opportunities and weaknesses in the market, and isolate the parameters necessary to implement XGnP Graphene Nanoplatelets into the market.

Team XG Sciences, through in-depth market analysis and implementation of effective business strategies, will provide a summary analyzing the practical applications of XGnP Nanoplatelets as a heat spreader in electronics. Our team will research current heat spreader technologies, identify opportunities and weaknesses in the market, and isolate the parameters necessary to implement XGnP Graphene Nanoplatelets into the market.

Through our research process, our team will complete a market and business analysis necessary for XG Sciences to apply its XGnP Graphene Nanoplatelets to the large market of electronics. Ultimately XG Sciences may provide an alternative to current heat spreader technology. Our goal is to help XG Sciences accomplish this task and be a strong force in the competitive market of electronics.

Team Members (left to right): Alex Dmoch, Norrin Jegla, Sean Kenny, Kristen Ballman, Alex Honey Project Mentor: Zach Tomlinson

Chrysler – Prototype Build Engineering: Standard Part Classification and Movement

Chrysler Group LLC is a subsidiary of Fiat S.p.A, an Italian automobile manufacturer. Headquartered in Auburn Hills, MI, it sells Chrysler, Dodge, Jeep and Ram branded vehicles worldwide. The Chrysler Corporation was founded by Walter Chrysler in 1925 and has experienced significant growth since. Currently, Chrysler employs over 65,000 people, producing over 1.6 million vehicles in 2012 and 2013 and generating over $65 billion of revenue in 2012.

Chrysler Group LLC is a subsidiary of Fiat S.p.A, an Italian automobile manufacturer. Headquartered in Auburn Hills, MI, it sells Chrysler, Dodge, Jeep and Ram branded vehicles worldwide. The Chrysler Corporation was founded by Walter Chrysler in 1925 and has experienced significant growth since. Currently, Chrysler employs over 65,000 people, producing over 1.6 million vehicles in 2012 and 2013 and generating over $65 billion of revenue in 2012.

Chrysler’s Prototype Build Engineering department is responsible for testing vehicles and parts by either adding parts to an existing vehicle (a mule build) or building a brand new vehicle (a prototype build). Currently there is no consistent method for classifying and storing incoming parts and moving stored parts from stockrooms to prototype build garages at Chrysler’s Auburn Hills facility. Using World Class Manufacturing standards, we will first categorize parts provided to us in a bill of materials. Once these parts are classified, we will develop a standardized system for storing parts and a process for moving parts throughout the Chrysler facility, ultimately eliminating non-value added

activities and improving efficiency.

Team Members (left to right): Nick Brinker, Rebekah Koschmann, Megan Seavoy, Hannah McQuade, Alexander Sims Project Mentor: Kalpana Prabhu

Peckham, Inc.: Increasing Efficiency: The Patagonia Jungle Shirt

Peckham is a clothing-manufacturing company that is a unique business and human services agency that values quality, diversity, and performance. They manufacture clothing for military customers as well as a few commercial customers. Critical elements of Peckham’s apparel business model include but are not limited to the following: cellular manufacturing (for optimized efficiency), LEAN manufacturing techniques, production goal setting, sewer training, assessment, and compensation, and preventative maintenance.

Peckham is a clothing-manufacturing company that is a unique business and human services agency that values quality, diversity, and performance. They manufacture clothing for military customers as well as a few commercial customers. Critical elements of Peckham’s apparel business model include but are not limited to the following: cellular manufacturing (for optimized efficiency), LEAN manufacturing techniques, production goal setting, sewer training, assessment, and compensation, and preventative maintenance.

Our project focuses on decreasing inefficiencies on a particularly challenging product line: the Patagonia Jungle shirt. This piece involves more complicated sewing patterns than many other lines, and therefore requires more training for the sewers. Due to the complexity of this garment and the high standards placed on Peckham by the customer, the garment is more challenging to produce than other products on the Peckham floor. We will review the manufacture of the jungle shirt, analyze the production system for waste, and locate possible knowledge or process gaps. Our deliverables will be recommended changes that will improve the efficiency of manufacture for the Patagonia Jungle shirt.

Team Members (left to right): Brittney Heatherington, Aaron Uherek, Robin Lawson, Brennen Oberski, Tyler Deal Project Mentor: Zach Tomlinson