ME 491 International Humanitarian Engineering is a design-intensive interdisciplinary course in which teams of students address the challenges of creating new products that enhance the lives of the poor, while respecting their social, cultural and ethical identities.

USAID: Modular Motorized Threshing Platform for Rural Zambia

Zambia is classified as a Least Developed Country and struggles with malnutrition and poverty. For their basic food, legumes are dense in micronutrients and protein, and when paired with maize, allow for a complete nutritional balance. Small and medium-scale farms in Zambia’s northern region produce the majority of the legumes that are consumed by Zambia. Conventional harvesting methods for legumes involve labor intensive threshing by hand that leads to low production rates. Adam Lyman, the team’s project collaborator, has previously implemented a mechanized legume thresher system that is powered by a bicycle. This system is excellent for small, resource-limited farms that are looking to improve legume production. However, medium sized farms are in need of a motorized system to meet the demand of their more substantive harvest. Pairing the current thresher with the modular motorized platform will enable farmers to increase their production rate to upwards of 100 kg per hour.

Zambia is classified as a Least Developed Country and struggles with malnutrition and poverty. For their basic food, legumes are dense in micronutrients and protein, and when paired with maize, allow for a complete nutritional balance. Small and medium-scale farms in Zambia’s northern region produce the majority of the legumes that are consumed by Zambia. Conventional harvesting methods for legumes involve labor intensive threshing by hand that leads to low production rates. Adam Lyman, the team’s project collaborator, has previously implemented a mechanized legume thresher system that is powered by a bicycle. This system is excellent for small, resource-limited farms that are looking to improve legume production. However, medium sized farms are in need of a motorized system to meet the demand of their more substantive harvest. Pairing the current thresher with the modular motorized platform will enable farmers to increase their production rate to upwards of 100 kg per hour.

When designing the modular motorized platform, the team considered design specifications unique to Zambian resources and culture, including cost, transportation, energy sources, and many others. System compatibility was a major factor because the motorized platform needed to work harmoniously with the current bicycle-powered legume threshing machine. Selection of the energy source ultimately determined the overall design of the system. Extensive research was done for both solar powered and internal combustion engine systems.

This prototype will be utilized to motorize a variety of otherwise manual farm equipment. Implementation of the modular motorized platform will allow small-scale farmers to increase their crop yield while saving on precious resources such as time and labor.

USAID: Zambian Peanut Farming – Human Powered Thresher

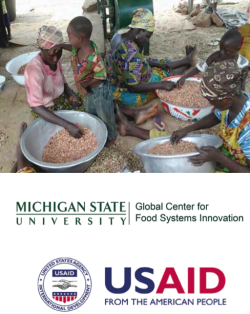

Zambia is populated by 15 million people and 60 percent live in poverty. The nation’s primary activity is agricultural production and this endeavor employs 85 percent of the workforce. Over 74,000 metric tons of groundnuts are produced annually by small- and medium-sized farmers, despite female farmers manually threshing only 1kg of nuts each hour. In order to enhance this productivity, and each family’s income, the team developed a human-powered device that threshes 100kg of peanuts each hour.

It is crucial to be able to visit the area of interest to meet the people the device will be servicing. However, as this was not feasible for the class, we have a collaborator, Adam Lyman, who is a Michigan State alumnus and is currently in Zambia. He serves as our eyes and ears in delivering a better understanding of the dominant culture and its people.

It is crucial to be able to visit the area of interest to meet the people the device will be servicing. However, as this was not feasible for the class, we have a collaborator, Adam Lyman, who is a Michigan State alumnus and is currently in Zambia. He serves as our eyes and ears in delivering a better understanding of the dominant culture and its people.

Ultimately, the team needed to “design and manufacture a modular peanut threshing machine that could be used by small- scale farmers in Zambia to de-shell and separate peanuts from their husks.” The nut is currently threshed manually by the farmers, which can cause long-term damage to the farmer’s hands. It is essential to not damage the nut when the shell is broken apart; the nut must come out “whole” (not split in half or cracked). In doing so, the team can not only impact the professional lives of the farmers but also impact their personal lives. The group expects the thresher to assist the female farmers in focusing on education, health and family issues rather than having to sacrifice their bodies and lives that are currently devoted to purely threshing.

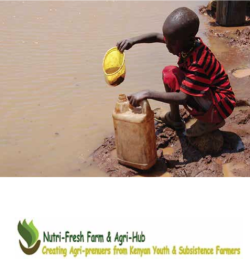

Nutri-Fresh Farm & Agri-Hub: Kenya: Human-Powered Water Pump

As Margaret Mead so wisely stated, “Never doubt that a small group of thoughtful, committed citizens can change the world. Indeed, it is the only thing that ever has.” One of the most important issues that must be changed is the current water crisis throughout large regions of our planet. Currently, 748 million people worldwide do not have access to high-quality, potable water. A vast majority of these underprivileged people live in Africa.

As Margaret Mead so wisely stated, “Never doubt that a small group of thoughtful, committed citizens can change the world. Indeed, it is the only thing that ever has.” One of the most important issues that must be changed is the current water crisis throughout large regions of our planet. Currently, 748 million people worldwide do not have access to high-quality, potable water. A vast majority of these underprivileged people live in Africa.

In Kenya, most families must walk many miles each day just to gather water from unsanitary sources such as stagnant mud holes. Woman and children are the main workforce for this exhausting, dangerous task. Gathering and using this water generally leads to numerous health issues caused by water-borne diseases such as dehydration, diarrhea, and many other possibly fatal illnesses.

Our team developed a device that efficiently retrieves water from boreholes and other natural water sources. The goal was to improve the health of local people by reducing the time and energy required to gather water, as well as to improve the quality and amount of water available to them. Considering that electricity may not be available and gas powered devices are expensive, the pump is human-powered. It is capable of retrieving water from depths up to 100 feet and is able to move a minimum of 200 liters per day. Achieving this goal will not only provide a steady source of water for Kenyan families, but all the benefits that come with it such as a cleaner home and enhanced personal hygiene, healthier and more fruitful gardens, more hydrated domestic animals, and more time in the day for activities such as schooling for the children.