MSU IPF Power and Water/Consumers Energy/Sartorius: Sustainable Energy Via Machine Learning

Michigan State Solar Racing Team: Custom Motor Controller for High-performance Solar Cars

Texas Instruments: Distributed Radar Sensing Networks

Texas Instruments: ML Methods for Object Classification using Radar

General Electric: Flight Simulator for Aviation

Fraunhofer USA, Center Midwest: Control System for Microfluidic Electrochemical Sensing

AMP Robotics: Robotic Grip System

MSU Bikes Service Center: Black Box for Bikes

Magna International Inc.: LWIR Sensor Array for High-Rate Temperature Control

Magna International Inc.: Design of Automotive Camera using RGB+IR Sensor

Magna International Inc.: Radio Frequency Power Transmission System

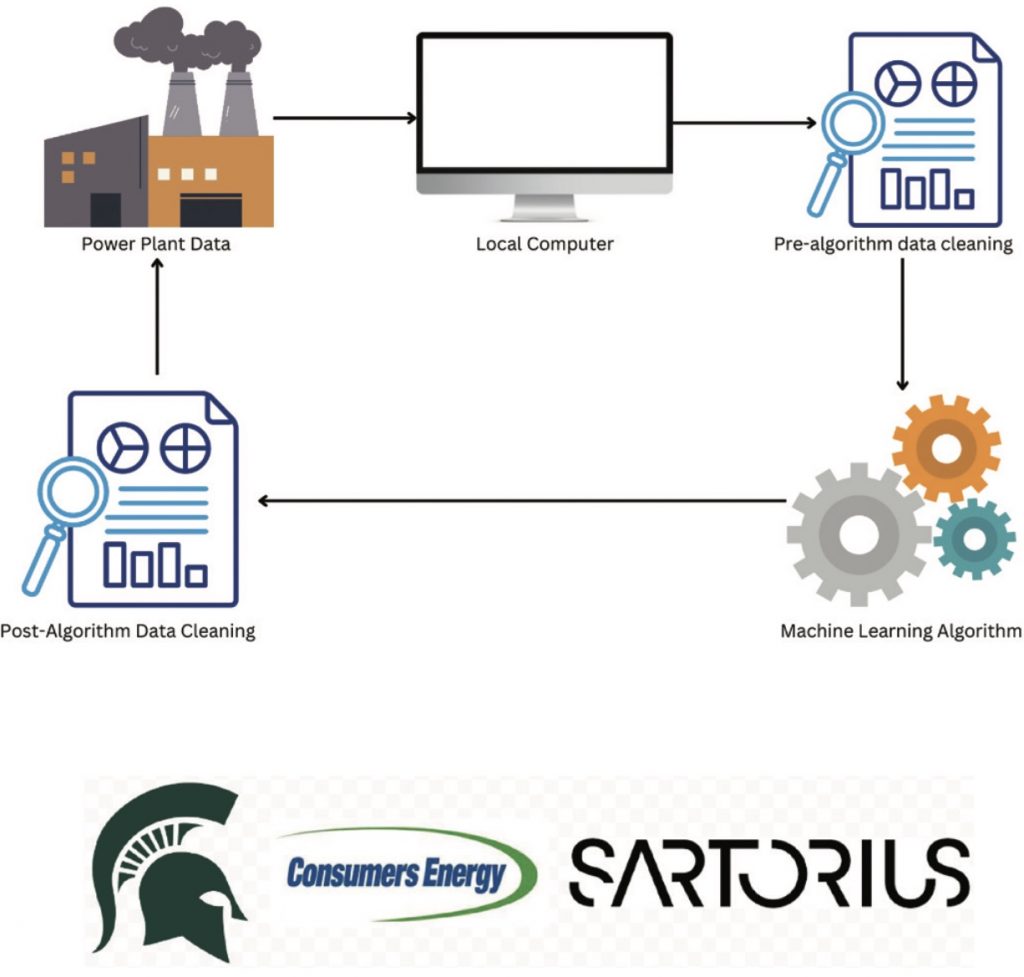

MSU IPF Power and Water/Consumers Energy/Sartorius: Sustainable Energy Via Machine Learning

Every year, Michigan State University expends approximately $20M in fuel to supply 300 GWh of electrical energy and 2 billion pounds of steam to campus. This process involves burning large amounts of fossil fuels. These fossil fuels are not only getting more expensive but are also harmful to the environment and contribute to climate change. Due to the size and complexity of a powerplant, there are many sources producing waste. The steam cycle has many possible inefficiencies: low condenser vacuum levels, high levels of condensate depression, fouled heat exchangers, etc. Inefficiencies potentially exist outside the steam cycles, such as around campus buildings where plant steam is utilized for heat.

The goal of this project is to find these inefficiencies and increase overall plant efficiency by utilizing methods of machine learning. By using a data historian provided by the T.B Simon Power Plant, data- points will be collected, sorted, and utilized by a machine learning algorithm to provide a better picture of where losses or increased emissions occur in the plant. The machine learning program should help find correlations between data points that would be difficult for a human to see.

To combat the periodic price increases and improve overall sustainability, the T.B. Simon Power Plant has installed software to continually track thousands of data points related to the powerplant overall. The staff of the powerplant would like a machine learning algorithm to parse through this huge amount of data and hopefully make connections that would be difficult for a human to detect. With this increased understanding of the plant, it could be possible to increase overall plant efficiency. If the overall efficiency of the plant is increased, this will help offset the rising fuel costs and help Michigan State University lower its carbon footprint.

Michigan State University

Team Members (left to right)

Josh Saba

Farmington Hills, Michigan

Patrick Bourke

Brighton, Michigan

Koltin Grammer

Stockbridge, Michigan

Ming Gu

Changzhou, China

Sarah Anderson

Okemos, Michigan

MSU IPF Power and Water/Consumers Energy/Sartorius

Project Sponsors

Greg Casee

Freehold, New Jersey

Nate Verhanovitz

East Lansing, Michigan

Teaching Assistant

Dr. Lalita Udpa

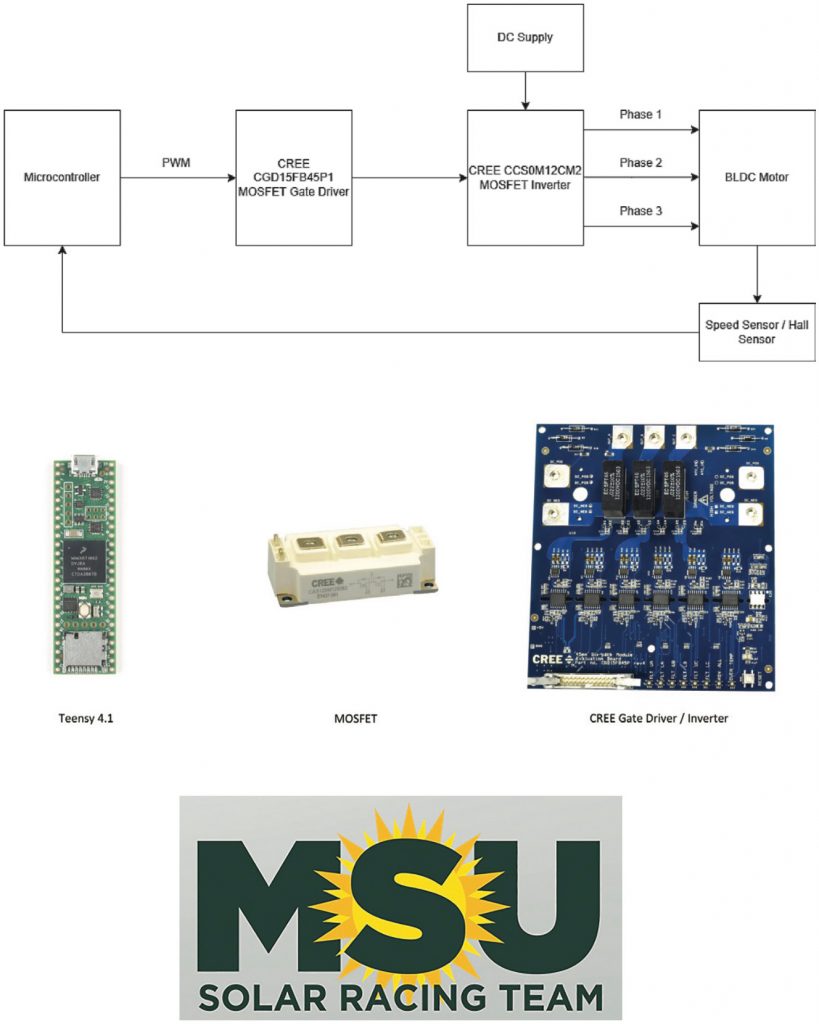

Michigan State Solar Racing Team: Custom Motor Controller for High-performance Solar Cars

The MSU Solar Racing Team is interested in a proprietary motor controller unit that can be utilized in the solar car. The task is to design, build, and program a controller with implementation of the correct sensors and hardware to meet these requirements. The motor will be a 3-phase brushless DC motor that will communicate via Computer Aided Network (CAN). This controller also needs to be able to regulate output of torque based on a throttle signal. Each of these criteria will need to be met, while packaging the controller in an ergonomic way.

Michigan State University

Team Members (left to right)

Erik Sparschu

Birmingham, Michigan

Michael MacKay

Birmingham, Michigan

Dylan Kutzleb

White Lake, Michigan

Brandon Mason

Riverside, California

Devansh Markan

Mumbai, India

Nick DeLisle

Union City, Michigan

Michigan State Solar Racing Team

Project Sponsors

Teaching Assistant

Dr. Virginia Ayres

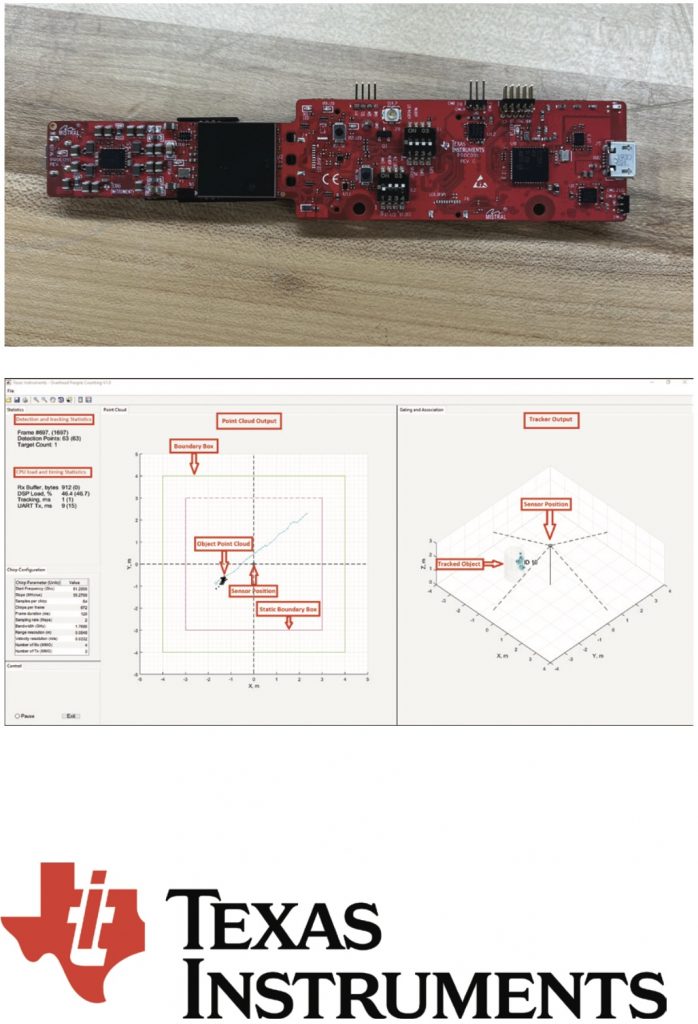

Texas Instruments: Distributed Radar Sensing Networks

Texas Instruments was founded in 1930 and is headquartered in Dallas, Texas. They are a global semiconductor company that designs, manufactures, and tests analog and embedded processing chips. Their main goal is to lower the cost of electronics through their advancements in Integrated Circuit (IC) technology.

Tracking with cameras is becoming less accepted, as people are not as comfortable being tracked when their identity is involved, due to advancements in facial recognition. In addition, cameras become increasingly less effective and more expensive when being used to track in the dark. Using radar, tracking can continue with less infringement on people’s privacy and also mitigates the need for light at a cheaper cost.

The project goal is for a sensor network of Texas Instruments mmWave radar sensors to be able to seamlessly track a person from one sensor to another within global coordinates. Currently, mmWave tracking is only processed independently, which means that one person will show up as two targets between the two sensors.

Our design will have two mmWave sensors that send data to a centralized processing machine, where the data will be manipulated and converted to a single coordinate system. The data is then displayed in a 2D map of the tracked region on a Graphical User Interface (GUI). The GUI will allow for easy calibration of the sensors and data visualization.

Michigan State University

Team Members (left to right)

Matthew Rapala

Dundee, Illinois

Adam Slavin

Trenton, Michigan

Joshua Springsteen

Williamston, Michigan

Michael Scepka

Oxford, Michigan

Lucas Hendershot

Howell, Michigan

Texas Instruments

Project Sponsors

Sudharshan Nagarathnam

Dallas-Fort Worth, Texas

Teaching Assistant

Dr. Daniel Morris

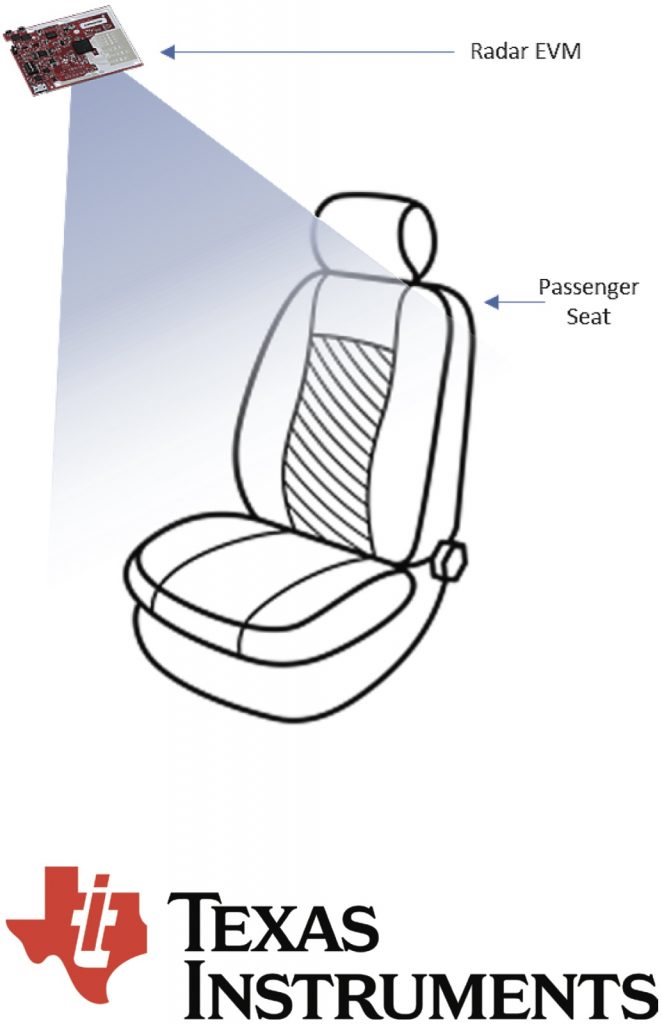

Texas Instruments: ML Methods for Object Classification using Radar

This project uses machine learning to classify an object in front of a radar sensor as live or not.

Our machine learning algorithms will observe unique patterns of objects using data collected by a Texas Instruments IWR6843ISK-ODS radar sensor evaluation module (EVM) and process that data with Python 3.7 and TI’s mmWave SDK 3.6 to determine the object’s nature using software.

Machine learning algorithms using Support Vector Machine (SVM), Convolution Neural Network (CNN), and Random Forest (RF) classifications will be developed and compared based on the accuracy of each algorithm.

The primary use case for this project is for detecting adults, children, and objects inside of a vehicle.

Michigan State University

Team Members (left to right)

Ashwin Kumar

Portage, Michigan

Emmanuel Bangura

East Lansing, Michigan

John Shafer

Saline, Michigan

Heyi Qu

Hangzhou, China

Jorge Pena

Monterrey, Mexico

Texas Instruments

Project Sponsors

Sudharshan Nagarathnam

Dallas-Fort Worth, Texas

Teaching Assistant

Dr. Nihar Mahapatra

General Electric: Flight Simulator for Aviation

Assured Position, Navigation, and Timing (A-PNT) is the catchphrase adopted by the U.S. Department of Defense to describe systems that accurately estimate the state of a mobile platform in any operating environment. A-PNT has emerged as an outcome of adversaries using electronic warfare to deny Global Navigation Satellite (GPS) systems by jamming or spoofing satellite signals. Due to these hindrances, GE Aviation has developed a prototype PNT system that employs a novel image-based method of geolocation, Vision-Based Navigation (VBN) to overcome drawbacks of GPS systems. For this project, we will be developing a flight simulator that will employ Unreal Engine (UE) along with Robot Operating System (ROS) and other related plugins, to simulate the required flight and environment system using manual controls that will be used in the future for VBN system testing purposes.

The objective of the project is to develop a simulation of a fixed- wing airplane operating in a 3-D virtual environment suitable for demonstrating the benefits of a prototype multi-sensor PNT system. The simulation will be created through use of UE 4.27.2. The aircraft for testing the simulation, provided by GE Aviation is a Boeing 737- 800. UE4 will implement the visual elements of the simulation, i.e. the fixed-wing airplane model and the photorealistic environment produced from an actual survey. The ROS plug-in will be used to implement the mathematical model of the vehicle flight dynamics. The flight simulation will be operated using manual controls, which includes the use of a control stick and a throttle, provided by GE Aviation. The final deliverable minimum of the project is a flight simulation that can display realistic environments and model the flight of the Boeing-737 in a mathematically correct manner, with the simulation being controlled manually using a control stick and throttle.

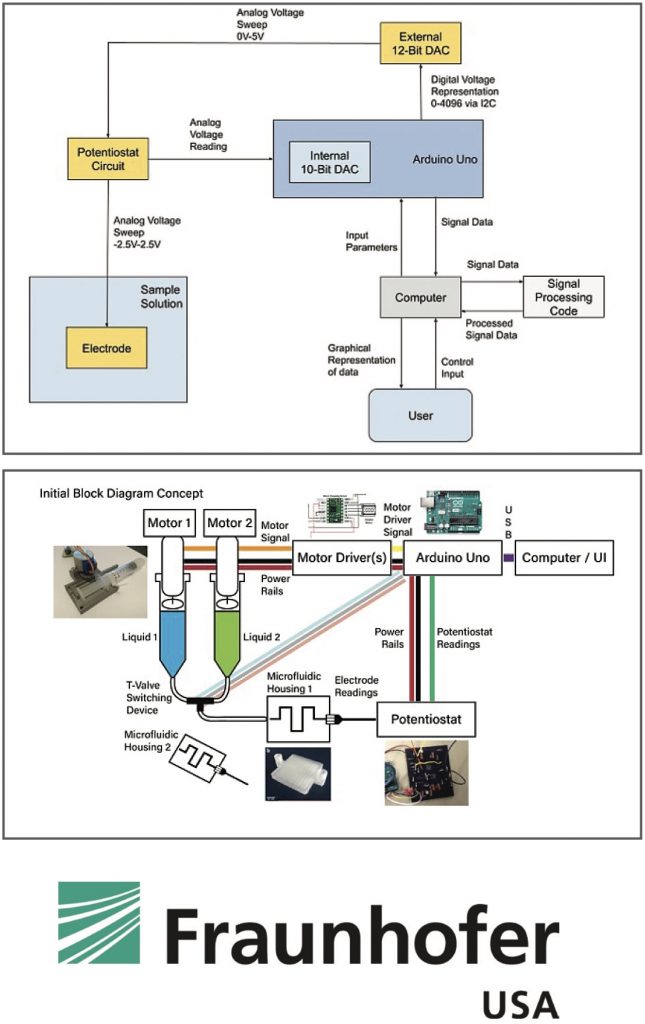

Fraunhofer USA, Center Midwest: Control System for Microfluidic Electrochemical Sensing

Fraunhofer USA, Center Midwest is a research organization in East Lansing, Michigan that specializes in diamond and coatings technologies. These technologies are used in several ways in the development of electrodes for electrochemistry utilization. The electrochemical uses of these electrodes include testing water samples for possible contaminants using small sample sizes, which is the purpose of the microfluidic control system.

A previous team’s design included a potentiostat circuit that, when connected to an electrode submerged in a water sample, used cyclic voltammetry to analyze the sample for potential solvents. The design also included a Graphical User Interface (GUI) when utilized with a computer. Because other testing methods are often single use, costly, and/or time-consuming, the design’s goal was to create a reusable, rapid, and cost-effective water testing system.

Our design is to improve upon the previously designed system by integrating a syringe-pumped flow-controlled system, 5V power source, specialized interchangeable housings for both a diamond and a printed electrode, and increase the portability of the system. The pumped system includes two syringes: one holding fluid to be tested, and the other to hold cleaning solution. The testing fluid will be pumped across the electrode connected to the potentiostat and GUI. The GUI controls syringe selection and flow rate, pumping the fluid between 1μL/ minute and 1mL/minute. The 5V power source replaces a 9V battery, and the specialized electrode housings enable electrode replacement or exchange. The entire system housing is space-efficient and lightweight to provide maximum portability.

Michigan State University

Team Members (left to right)

Kent Bazman

Pinckney, Michigan

Spencer Barrer

Royal Oak, Michigan

Timothy Boyd

Detroit, Michigan

Conner Graham

Grand Rapids, Michigan

Daniel Hawkins

Mason, Michigan

Fraunhofer USA

Project Sponsors

James Siegenthaler

East Lansing, Michigan

Teaching Assistant

Dr. Peng Zhang

AMP Robotics: Robotic Grip System

The MSU Recycling Center houses and uses an AMP Cortex Robotic sorting system that uses suction to organize recyclables from a moving belt. The system needs improved pick accuracy, which can be achieved through a tested successful algorithm. Our team is tasked with developing this algorithm and achieving a 95% successful pick rate.

The AMP Cortex robotic system, designated MRF-E (“murphy”), sorts category 1 (polyethylene) and category 5 (polypropylene) plastics from a moving trash belt. It is important to differentiate bad picks from good picks because the belt may contain a variety of other plastics and metals.

Success may be achieved through image processing, additional sensors, or integrated programming. We have chosen to achieve our goal by integrating the program and creating/ improving on the current algorithm that MRF-E is using.

By doing this, we will be able to deliver what is requested of us in a timely manner, and meeting standards that AMP Robotics expects.

Michigan State University

Team Members (left to right)

Jace Pidhirny

Pittsburgh, Pennsylvania

Benny La

Grand Rapids, Michigan

Abbas Akhdar

Troy, Michigan

Aidan Monroe

Wadsworth, Illinois

Alison Otis

Endwell, New York

AMP Robotics

Project Sponsors

Amanda Marrs

Broomfield, Colorado

Matthew Stanton

Broomfield, Colorado

Teaching Assistant

Dr. Bige Unlnturk

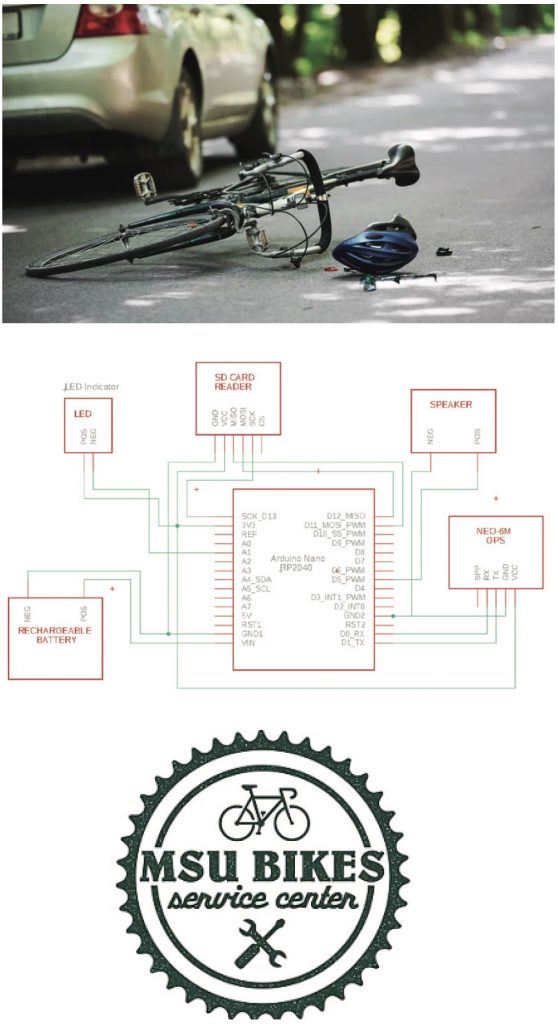

MSU Bikes Service Center: Black Box for Bikes

The MSU Bikes Service Center has been a part of the Michigan State University Community since 2003 when it started as a volunteer-run project. In 2006, it received funding from Michigan State University to open its doors at its present location on Farm Lane.

In 2021, MSU was recognized with a Gold Level Bike Friendly University award from the League of American Bicyclists. In keeping with its bike friendly environment, our team has partnered with the MSU Bikes Service Center to create a device capable of detecting bike incidents.

Due to the heavy traffic associated with MSU students, faculty, staff and visitors commuting to and from class, bike incidents have become a common problem. This is understandable when one considers that the fall 2022 enrollment of MSU topped out at an astonishing 50,023 students.

Our team’s goal is to develop a weather resistant device that is mounted discretely on a bike. This device will then be based around an Arduino Nano microcontroller that will have the ability to track certain parameters such as acceleration, orientation of the bike (gyroscope), and GPS location to help determine if a crash has occurred.

Overall, the device we create will enable these incidents to be recorded, allowing MSU to take a deeper look into the more accident-prone locations around campus, which could ultimately lead to improvements in infrastructure around campus to help increase safety for both riders and non-riders.

Michigan State University

Team Members (left to right)

Kyle Lawson

Farmington, Michigan

Tony Doyle

Manitou Beach, Michigan

Ethan Gleason

Empire, Michigan

Emma Stanavich

Chelsea, Michigan

Tyler Vo

Holland, Michigan

MSU Bike Service Center

Project Sponsors

Tim Potter

East Lansing, Michigan

Teaching Assistant

Dr. Sunil Chakrapani

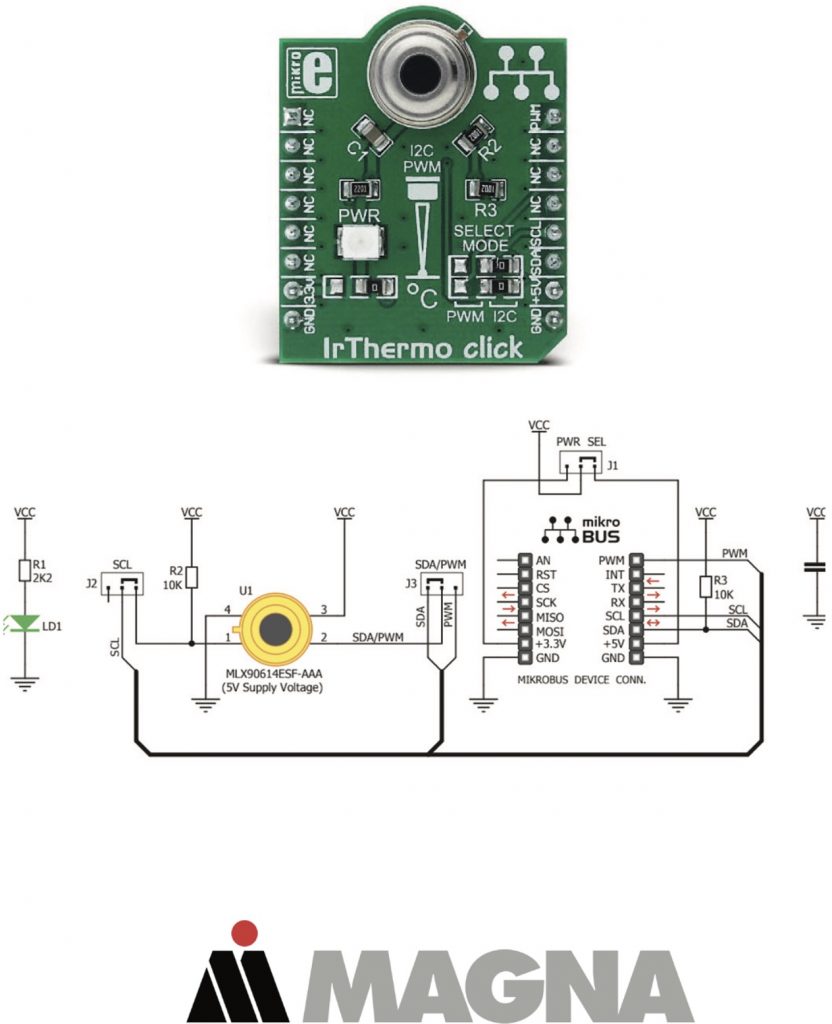

Magna International Inc.: LWIR Sensor Array for High-Rate Temperature Control

Magna International Inc., founded in 1957 is a Canadian parts manufacturer for automakers. Magna is the largest automobile parts manufacturer in North America. It produces automotive systems, assemblies, modules, and components which are supplied to major automotive companies.

Temperature control is very important to electronics as it enables the device to maintain an operating temperature that will not cause damage. Our project involved the temperature control of LED lights, which has an automotive application in the headlights of vehicles. Currently, thermistors are being used to monitor and control temperature within circuit designs for this application, however they are not perfect and can vary greatly by design. They also display a continuous upward slope in temperature when in reality the temperature is not increasing linearly.

Our project is to design and test a high-rate temperature sensor for electronic assemblies based on Long-Wave Infrared Array (LWIR). The system’s heat dissipation and high-rate control will initially be simulated using MATLAB Simulink. The sensor hardware will then be integrated to a circuit that dissipates enough heat for characterization and according to simulations. For this project, the team goal is to be able to test and show that the temperature control unit is able to take data at a higher sampling rate and respond more quickly to changes in temperature when compared to a conventional system that uses a thermistor. In order to confidently compare the two and validate our work, the team will simulate and physically test both thermistor and sensor circuit designs.

With the successful completion of this project, Magna International will be able to consider implementing thermal sensors into future designs in place of thermistors.

Michigan State University

Team Members (left to right)

Isabella Cureton

Northville, Michigan

Erin McAlinden

Livonia, Michigan

Griffin Forrester

Traverse City, Michigan

Kevin Chen

Troy, Michigan

Zhifeng Ji

Ningbo, China

Magna International

Project Sponsors

Daniel Carballo

Rochester Hills, Michigan

Teaching Assistant

Dr. Peng Zhang

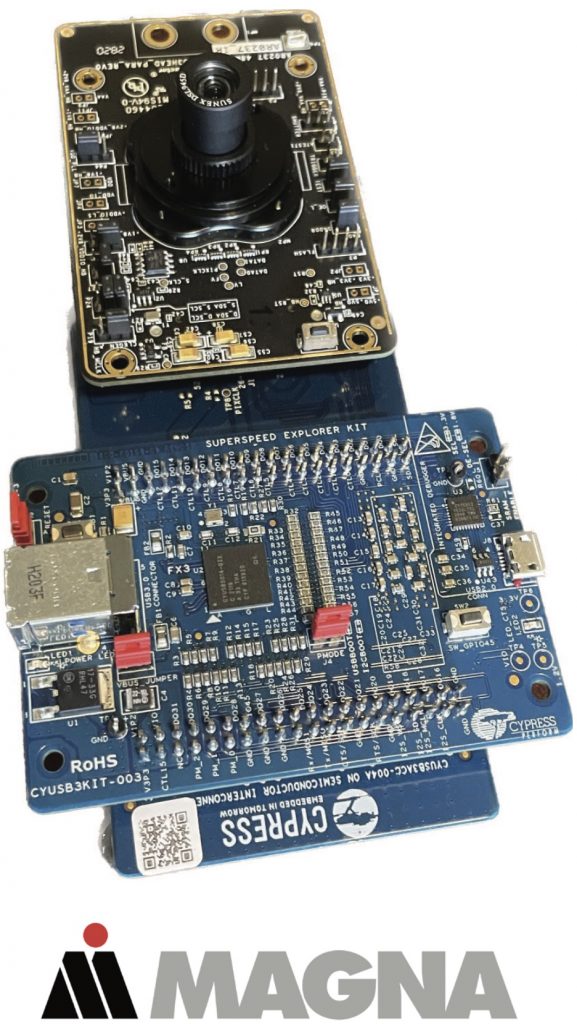

Magna International Inc.: Design of Automotive Camera using RGB+IR Sensor

Magna International Inc., founded in 1973, is a leading parts designer for automotive manufacturers. Headquartered in Aurora, Ontario, Magna has hundreds of manufacturing operations and develops dozens of different products worldwide. Magna has been working on automotive technologies for decades, and became one of the first companies to develop rearview cameras for automakers. In recent years, this drive for innovation in the automotive industry has led Magna to look into RGB+IR technology for automotive camera applications.

This project has dived deeper into whether RGB+IR technology has a net benefit over traditional RGB technology. The specific emphasis was on whether the RGB+IR sensor had a net benefit over traditional RGB cameras in low-light environments. Important components included the ability to distinguish objects or people in the collected images. By collecting additional data for Magna, this group will finalize whether or not there is a net benefit to including IR technology in automotive cameras. This project also will determine any benefit of IR technology in low-light environments and any advantages presented over traditional RGB camera technology.

Michigan State University

Team Members (left to right)

Aidan Fadool

West Bloomfield, Michigan

Bryan Clarke

Ludington, Michigan

Nick Dehoek

Grandville, Michigan

Jonathan Chereson

Shelby Township, Michigan

Leo Crepeau

Beverly Hills, Michigan

Magna International

Project Sponsors

Daniel Carballo

Rochester, Michigan

Teaching Assistant

Dr. Qi Hua Fan

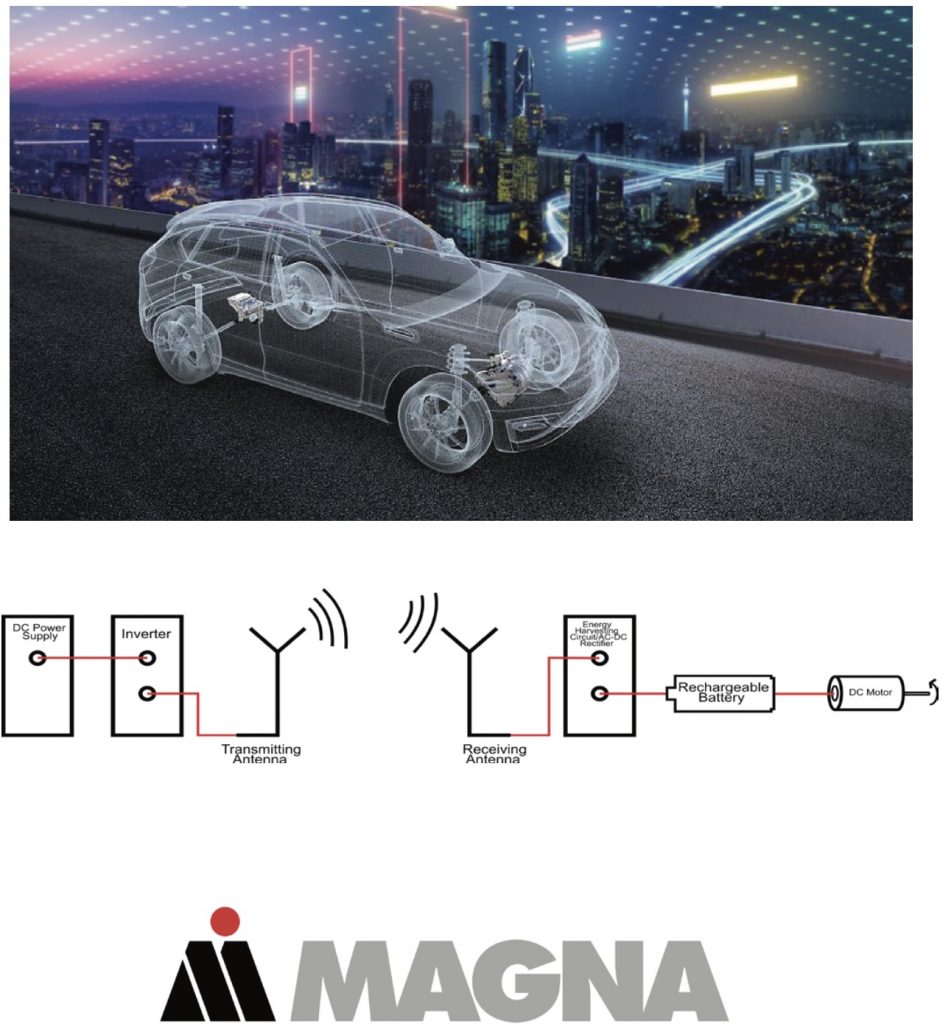

Magna International Inc.: Radio Frequency Power Transmission System

Since 1957, Magna International Inc. has prided itself on developing technologies, systems and concepts that make vehicles safer and cleaner, while serving communities, the planet and, above all, people. They are a leading global automotive supplier with 341 manufacturing facilities and 89 product development, engineering and sales centers in 28 countries. Magna International develops and manufactures products and systems in the areas of body exteriors and structures, including power and vision technologies, seating systems, powertrain systems, electronics, mechatronics, interiors, and control modules.

Magna International approached our team with the task of designing a Radio Frequency (RF) system that allows power transmission through electromagnetic resonance. Electromagnetic resonance is highly demanded in many fields, as it can power multiple devices from one power source. In particular, the automotive industry is looking toward the use of RF-enabled wireless power transfer for low-power electrical devices within the cabin, such as seats and side mirrors. Currently, cables are used to make these power connections in vehicles, which takes up room in the cabin, interferes with other components, and raises concern over time with constant movement of the vehicle.

The goal of this project is to design an RF system that enables power transmission via a 12V supply. This will be done through transmitter and receiver antennas and be able to power two DC motors. Our team will verify this transmission of power and estimate losses by performing an efficiency of power evaluation for the electrical system. Magna International will consider our high- level proof of concept for future possibilities of being able to transmit power wirelessly through an RF transmission system.

Michigan State University

Team Members (left to right)

Daniel Karczmarczyk

Warren, Michigan

Carter Mayfield

Plymouth, Michigan

John Murdoch

Lansing, Michigan

Jennifer Rousseau

Westland, Michigan

Elijah Savoie

Lansing, Michigan

Magna International

Project Sponsors

Hussein Farhat

Troy, Michigan

Teaching Assistant

Dr. Ming Han