American Axle & Manufacturing: AAM NA Transportation Network Optimization

Asahi Kasei Plastics North America: Raw Material Planning & Stock Replenishment Strategy

Blueair: Air Purifier Refurbishment

BP: Measuring the Carbon Footprint of Complex Global Supply Chains

BP: Asset Re-purpose Hub – Net Zero 2050

Caterpillar: Integrating Sustainability into a Global Supply Chain & Logistics Operations

Caterpillar: Forecasting Method Proposal

Clarience Technologies: Telematics Project

Clarience Technologies: Supply Base Size, Capability and Footprint

Consumer’s Energy: Supplier Diversity Workstream and Vendor Analysis

Gerdau: Design an Order Management Process for Finishing Capacities

Gerdau: Order Management Process | Data Analysis

Hanson Logistics: Cold Storage Facility Layout & Design

John Deere: Consolidated Warehouse Packaging Solution

John Deere: Supplier Performance Predictability Tool

KLA: Michigan and Midwest Region Supply Chain Opportunities

L3Harris – Combat Propulsion Systems: Transmission Ball Piston Supply System Design

MSU Infrastructure Planning and Facilities: Energy Efficiency and Operations Dashboard

MSU Infrastructure Planning and Facilities: Preventative Maintenance Program on Airflow Measuring Stations

NASA Psyche Mission: NASA Creativity Competitions

NASA Psyche: Mission to a Metal World: Launch Lead-Up Analysis

Parker Hannifin: The Indirect Course

Smith+Nephew: Replenishment Optimization Initiative

Smithfield Foods: Automated Trailer Loading Savings Potential

Trane Technologies: Indoor Air Quality Category Approach

American Axle & Manufacturing: AAM NA Transportation Network Optimization

American Axle and Manufacturing is a tier one automotive supplier, dealing in driveline and drivetrain components and systems. AAM is based in Detroit, Michigan, with over 80 locations spanning from the Americas to Asia and Europe, generating a global presence. Contained within AAM’s locations is a complex transportation network of freight, ranging from raw materials to finished goods. A combination of different transportation methods are utilized by the company, such as Truckload, LTL, LTL Consolidation, International Air and Ocean, and Premium Transportation. The team’s main focus revolved around analysis of American Axle’s North American transportation routes.

Our team worked on a project towards optimizing the transportation network of American Axle. Although the project focused on transportation specifically in North America, there was an emphasis placed on transportation within the United States. The team acted as a fresh set of eyes on transportation data and trends within AAM, with plans of identifying areas where AAM could improve its network and add value within their organization.

Project opportunities focused on determining why specific types of transportation modes were used based on individual scenarios. Important metrics included shipment weight, shipment frequency, transportation mode, and asset utilization. These key indicators were targeted when analyzing the transportation mode utilized. When looking deeper into the data and trends, different applications could be utilized to assess which areas had high concentrations of spend to find cost saving opportunities. Certain transportation modes and suppliers are utilized more frequently than others and being able to consolidate or capitalize on certain opportunities could lead to unseen savings. Each factor analyzed aimed to reduce American Axle’s total spend on transportation. The team’s analysis hopes to help AAM further their cost savings in a rapidly changing logistical environment.

Asahi Kasei Plastics North America: Raw Material Planning & Stock Replenishment Strategy

Asahi Kasei Plastics North America operates two facilities that manufacture plastic compounds. One facility is in Fowlerville, Michigan and the other is in Athens, Alabama. The planning team for Asahi Kasei Plastics oversees monthly forecasts for sales of finished goods, but the ongoing COVID-19 pandemic has made it difficult to be prepared for the continuous fluctuation in demand’s effect on raw materials. As their purchasing team currently orders raw material based on its historical usage, this dramatic fluctuation in demand causes frequent raw material shortages, as well as instances of excess inventory.

Asahi Kasei Plastics partnered with Michigan State University to create a processing tool to better estimate the future usage of raw materials, and make sure the plant has an appropriate inventory of raw materials on hand. This tool also aids Asahi Kasei Plastics in reducing their inventory discrepancies and improving their stock replenishment efficiency.

With the data provided from Asahi Kasei Plastics, we created a data analysis tool in Excel with the ability to use the changes in demand forecast of finished goods and lead times of raw materials to predict the upcoming use of raw materials, as well as to create an efficient order schedule for raw materials. This was done by converting finished goods forecasts to raw material forecasts, and calculating appropriate lead times, reorder points, safety stock, and lot sizes. The tool was created with emphasis on integration and flexibility. This means inputs to the tool can be altered or added, and the tool still calculates desired outputs.

Blueair: Air Purifier Refurbishment

Blueair was founded in 1996 as a producer of air purification solutions for both home and professional use. The company is headquartered in Stockholm, Sweden. Blueair delivers innovative, best-in-class, energy-efficient products with the purpose of improving the health and well-being of people everywhere.

For this project, Blueair has enlisted the team to help create

a standard process for refurbishment for three of its air purifier

models. Our team has been tasked with developing a unique set

of standard operating procedures for each model. We will also be creating a cost analysis for each unit and utilizing a decision-tree style model for determining whether parts should be replaced, reused, or if the returned unit should be scrapped altogether. The completed guide will assist Blueair employees with decisionmaking through each step of the refurbishment project, from receipt defective/damaged units to the repacking of fully refurbished units.

The team has disassembled each unit and reviewed part lists

and pricing information for every component included within the air purifiers. All of this information will be combined and used moving forward to develop the necessary standard operating procedures and cost analysis. The standard operating procedures will be a thorough, step-by-step list guiding the entire refurbishment process. It will be written clearly enough that anyone unfamiliar with the product and process could follow the steps and complete the procedure successfully.

This project will benefit the company by increasing profitability and reducing waste. Currently, there is not an established procedure for this process, so this will increase efficiency. By enabling the company to reuse more components, this set of procedures will serve to eliminate waste and increase sustainability.

BP: Measuring the Carbon Footprint of Complex Global Supply Chains

BP is one of the world’s seven largest oil and gas superpowers and supplies energy globally with operations in almost 80 countries. BP can trace its roots back over 100 years and continues to provide energy solutions in traditional and innovative ways.

As energy needs grow and the environmental impact of traditional energy sources comes under the global spotlight, BP is seeking to reduce their greenhouse gas (GHG) emissions. These efforts will pave the way to a more sustainable and efficient future of energy.

In order to effectively reduce emissions, our project seeks to understand impactful methods for measuring and reporting GHG emissions. One of the most difficult areas of carbon footprinting for an organization is mapping its upstream and downstream supply chain emissions. Traditionally, these solutions are complex and global, following “make-use-dispose” models that do not take disposal or recycling into account.

As of January 1, 2021 BP has combined reporting for their upstream and downstream supply chain emissions. Since they were previously separate, they lacked cohesive emissions tracking initiatives. BP aims to be net-zero by 2050, and a large step towards achieving that goal is decarbonization of their supply chain.

By reviewing current supply chain emission measurement methods used by industry leaders, primarily those outside of the oil and gas industry, our team will analyze best practices of carbon footprinting. This will result in an outline for supply chain emission modeling practices for BP. By applying these best practices to BP’s supply chain, the company will have the capabilities to target areas of the supply chain that carry the biggest footprint.

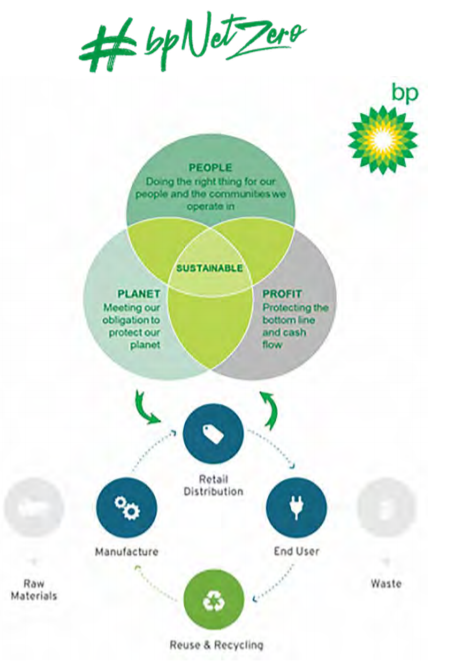

BP: Asset Re-purpose Hub – Net Zero 2050

BP is a British multinational oil and gas company headquartered in London, England. It is one of the world’s major oil and gas firms. A main challenge that BP currently faces is that there is no standard way to re-use, re-sell, or recycle assets when a business unit has a move or change event. Everything is done manually and there is disconnect between the Property Management organizations. With this challenge, the BP Supply Strategy & Innovation Team has identified an opportunity to run a beginning proof-of-concept for re-use of office furniture & other assets. The

long-term goal for the “BP Asset Repurpose Hub” is to become a centralized portal to re-use, re-sell, or recycle BP’s assets. This portal will enable them to increase the circularity of their current assets, consequentially reducing the use of virgin resources and decreasing resource intensity. In addition to reducing costs that could otherwise be reallocated, utilizing a centralized portal aids in reducing emissions, thus facilitating BP’s goal to be net-zero by 2050.

One key deliverable for this project is to develop a functioning prototype portal that enables users at BP to upload assets from select sites for internal repurposing or external sales. The minimum capabilities required of the portal include the ability to

upload an image, description, and current location of the asset. The other deliverable is a process map detailing the steps required to re-purpose an asset beginning with placing an asset in the portal and ending with delivery to the end customer.

Low-risk assets, such as office furniture and conference room equipment are in-scope for this project. Direct materials, such as oil, and operating assets like turbines and heavy machinery, are out of scope. The scope is limited to 1-2 office sites that will serve as pilots for the prototype hub. These sites will be selected by the project sponsor. Also, in-scope is an assessment of the viability of third-party platforms and BP’s internal technology for use as the long-term host of the hub. Internal financial processes associated with the hub are out-of-scope. With the development of the Asset Re-Purpose Hub, BP will now have a tool to assist with their sustainability initiatives and bring specific benefits in areas such as financial, non-financial, and carbon reduction. In addition to these benefits, the portal will be another powerful resource for the entire organization to utilize.

Caterpillar: Integrating Sustainability into a Global Supply Chain & Logistics Operations

Caterpillar is the world’s leading manufacturer of

construction and mining equipment, diesel and gas

engines, diesel-electric locomotives, and industrial gas

turbines. Caterpillar has been working toward building a better

world through innovation and sustainability progress on every

continent.

The focus of the project was to identify and analyze

sustainability efforts and ideas that will allow Caterpillar to

continue to provide service and products to its customers while

at the same time minimizing global impact. Through analyzing

and identifying sustainability risks and opportunities within the

logistics infrastructure at the Lafayette, Indiana plant, the project

gave Caterpillar the tools needed to enable economic growth and protect the planet.

Some initiatives developed by the team to improve Caterpillar’s sustainability included opportunities to drive reductions in BPM, CO2 Emissions, and water consumption. Also, the team analyzed and suggested volunteer opportunities to engage employees of all job types and generations. While investigating the sustainability opportunities already in place, the team ensured that Caterpillar’s sustainability council was focused on the right sustainability efforts. Caterpillar’s company mission statement is “to enable economic growth through infrastructure and energy development, and to provide solutions that support communities and protect the planet.” Throughout the semester, we focused on investigating, analyzing, and comparing sustainability efforts within Caterpillar itself and the surrounding industries to minimize the environmental footprint.

Caterpillar: Forecasting Method Proposal

Caterpillar receives forecasting estimates from its customers and uses a coded process with 40 iterations based on each customer to determine what the customer order will be. With this current process, the forecast determined from the customer predictions is often unreliable and inaccurate. As a result of this, Caterpillar experiences shortages or excess in

inventory due to the inaccuracy of the forecast.

Our team will use their analytical skills to help improve this process. Caterpillar provided crucial data for this project which included forecasting projections and actual orders for five customers, each customer containing 100 parts. Caterpillar and our team agreed that they needed to examine samples of five customers in order to be able to analyze and make meaningful assumptions to help improve the process.

We will be working to create a model that will improve the forecast accuracy by changing and implementing weighted averages and combining the data of all customers. The goal is to make the system and formulas more simplified which will create a more efficient system for Caterpillar to improve the forecasts for their customers. Along with this, we will work to reduce the number of iterations used in the forecasting analysis to create a more productive process with less variability between the forecasted data and actual demand.

Our team will use platforms such as Excel, Tableau, PowerBI and R Studio to analyze Caterpillar’s data. Excel will be used to find the variability between Caterpillar’s forecast and actual demand data, and the other platforms will be used to create a dashboard that can easily be managed and turned into a more efficient process for Caterpillar to monitor their customer(s).

Clarience Technologies: Telematics Project

Clarience Technologies began in 1955 with an ingenious idea

that sparked a revolution in truck and trailer safety lighting.

Clarience is comprised of a family of brands with the mission

of providing total visibility to the transportation industry. Their family of brands includes Truck-Lite, Davco, Road Ready, Rigid, Lumitec, and most recently ECCO and Code 3. With data and insights provided through advanced technology, Clarience Technologies is able to provide customers a complete fleet management solution, streamline supply chains, and enhance safety both on and off the road.

This project focuses on Clarience’s Road Ready telematics

division, which provides fleets with real-time, exception-based reporting and allows for improved fleet control. Road Ready’s solutions include GPS location, mileage and speed tracking, light out detection, ABS and tire inflation warning, temperature, standard and volumetric cargo, door status, TPMS, wheel end condition, and more.

Currently, Clarience’s Road Ready products are prominent in

the heavy-duty tractor trailer market. This market has over 6 million trailers with only an estimated 30% having telematics capability. This provides Clarience with a large growth opportunity. To capture additional markets Clarience Technologies is looking to expand the Road Ready solution into three adjacent markets: final-mile, rail, and ocean.

We will conduct market research and SWOT analyses on the three respective markets (final-mile, rail, and ocean) to uncover potential growth opportunities with the introduction of Road Ready Products. Macro-level and micro-level market research will identify the key industries and major companies within each market segment. In parallel, company surveys will be administered to locate current gaps in supply chain visibility and opportunities to help customers maximize asset utilization and boost operational efficiency.

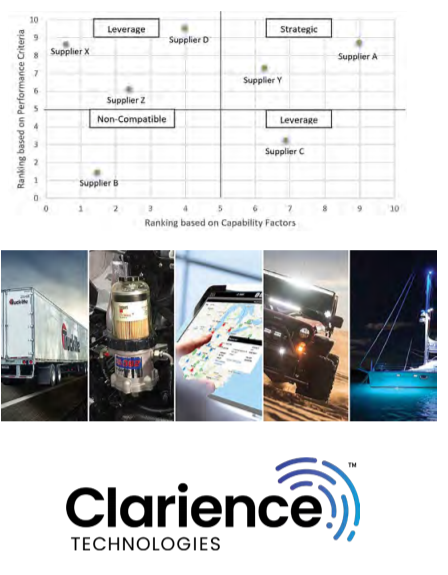

Clarience Technologies: Supply Base Size, Capability and Footprint

Clarience Technologies is a leader in vehicle electronics with

an international presence. Established in 2020, Clarience

Technologies utilizes its 8 divisions that include Truck-Lite,

Road Ready, Davco, Rigid, and Lumitec to provide total visibility

to transportation. With these divisions, Clarience Technologies

specializes in lighting, wiring, sensors, and filtration products for

the commercial vehicle, military, recreational, and marine industries.

Our project is focused on developing a supplier capabilities

matrix and survey that will be used across all 8 divisions of Clarience Technologies. The survey will act as a template to gather qualitative and quantitative data on current and future suppliers to be used in the matrix. The matrix will provide relevant capability data for an easy and accurate evaluation of all suppliers. With over 1,000 suppliers, this matrix will help Clarience Technologies identify and optimize its supply base.

Our team will create this matrix by sending the survey that

we create to all suppliers of Clarience, and using the gathered data

the team and Clarience will be able to make educated decisions

about the present and future of their supply base. There will be questions to determine general knowledge about the suppliers, and also tailored category questions based on the division of Clarience with which the supplier is working. On top of this, we will use our matrix to make our own recommendations about the supply base or a few specific categories of Clarience based on a category-unique weighting system that we create.

With the completion of this project, Clarience Technologies will have a supplier survey and capabilities matrix that will greatly reduce sourcing time for new parts. The supplier matrix will also serve as a long-term template for future supplier capabilities analysis.

Consumer’s Energy: Supplier Diversity Workstream and Vendor Analysis

In 2019, Consumers Energy committed to spending $7.5 billion over a five-year period within Michigan-based businesses and doubling the allocated budget spent on diverse suppliers. This commitment led to Consumers Energy wanting to build a better connection with aspiring suppliers, which created a pathway for this project. Every company that applies to be a supplier at Consumers Energy must go through a bidding process and is referred to as an “aspiring supplier.” This means that they have finished their application but have yet to be offered a vendor contract. Consumers Energy identified a gap in this supplier journey and asked the team to come up with three or four implementable strategies to improve this supplier experience. More specifically, these solutions will help

close the gap in this process and keep CE suppliers engaged before they’re offered a contract.

Our team began the project by conducting industry research on loyalty and membership programs. In order to gather data on expectations/desires, we conducted multiple Empathy Interviews with aspiring suppliers in the Consumers Energy database. These interviews allowed us to better understand the needs and wants of the aspiring suppliers without making assumptions. It also helped guide us as to what process improvements would be most effective. A Pareto chart was then used to organize and analyze the data so we could identify the most prevalent expectations and desires from the aspiring suppliers. A survey and second round of interviews were conducted with the same aspiring suppliers, in which our team presented the recommendations and gathered feedback on the ideas.

The team then finalized their strategies, and a process map was created. The implementation of these strategies will improve the process experience for aspiring suppliers and will allow Consumers Energy to reach their commitment of diversifying spend and working with Michigan-based businesses.

Gerdau: Design an Order Management Process for Finishing Capacities

Gerdau is one of the largest suppliers of steel in the world.

Their core business is to transform steel scrap and iron ore

into product. While promoting sustainable development,

Gerdau converts millions of tons of automotive packaging and

appliances scrap into new steel products to ship all around the

world. Currently, Gerdau’s facility in Jackson, Michigan relies on paper tags and manual intervention to ensure the right material is loaded and shipped. This process often results in human error, reduces customer satisfaction, and can be costly. Due to human error, customers have received correct material with incorrect tags as well as incorrect material altogether. Gerdau’s focus is on improving their shipping department by designing an order management process.

The order management process Gerdau is looking to implement will utilize Radio Frequency Identification (RFID) technologies.

RFID technology ensures that a manufacturer can track exactly

what products are leaving their facility and their status. Since RFID does not rely on manual intervention, this will help mitigate human error, improve efficiency, and increase customer satisfaction.

The goal of the project is to propose two possible solutions for implementing RFID within a specific department in Gerdau’s Jackson facility. One solution will be a low capital investment that may not yield the most optimal results but will reduce the likelihood of a shipping mistake. The other solution will be an increased capital investment that will drastically reduce the likelihood of a shipping

mistake occurring.

In order to propose the best solutions, it is vital to understand Gerdau’s current tagging system, conduct extensive research, and contact potential suppliers of RFID tags and systems.

Gerdau: Order Management Process | Data Analysis

Gerdau is a steel manufacturing company offering a range of long steel and specialized steel products from mills across the United States. This project is supporting the Sales and Operation Planning division of the Supply Chain Management department within Gerdau to

improve upon the current process for order management. The current order management system is a manual Excel process consisting of multiple data sources that require manual

extraction and cleansing. This project is focused on cleansing, organizing, and automating multiple data analysis processes to provide an improved system for order management.

Utilizing PowerBI, our team was able to automate the data extraction process for inventory levels, thus removing the manual data updating and cleansing processes. The consolidation of multiple data sources provides a more user friendly streamline of information. This resulted in an 86% increase in efficiency, as well as the ability to better forecast customer demand.

To better assess inventory capacity and reduce

overbookings, comparisons between past due finished goods

and current bookings data were made to assure customers do

not overbook on current orders when they have yet to retrieve

their past due orders.

By formatting and consolidating data from numerous

sources, we were able to develop a comparative analysis

of long lead products at Gerdau facilities. Utilizing this

comparison, supply chain analysts can more clearly visualize

the production levels and possible bottlenecks in various

factories. It also functions as an effective tool to forecast

increasingly accurate delivery estimates for customers.

Hanson Logistics: Cold Storage Facility Layout & Design

Hanson Logistics is an all-encompassing transportation, warehousing, and temperature-controlled distribution company headquartered in Saint Joseph, Michigan. With the demand of cold storage on the rise, more than 250 Hanson associates work across 8 locations to provide end-to-end supply chain solutions, making them one of the largest providers in the US. With a business model that deals with case pick operations on a daily basis, the focus for the project is to improve the process of consolidation of the outbound shipments in an effort to decrease unnecessary movement

and save time.

The objective of this project is to collaborate with the Hanson team to reformat the layout and positioning of products within their Hobart, Indiana facility. In doing this we will be able to minimize the amount of distance forklift drivers travel throughout the facility, thus maximizing efficiency. Through analysis of facility layout and pick operation data, an improvement plan will be created, laying out the steps that need to be taken to implement the improved processes.

Specifically, we will identify the top 20 customers at the Hobart facility to assess where the fastest moving products are stored.

From there, a new process plan will be implemented to reallocate products with higher inventory turnover to more optimal locations throughout the warehouse. This will allow products with high case pick frequency to be stored closer to the loading docks, leading to a drop in cumulative distance traveled for forklift drivers. In doing so, both energy and time will be saved, increasing performance and saving money

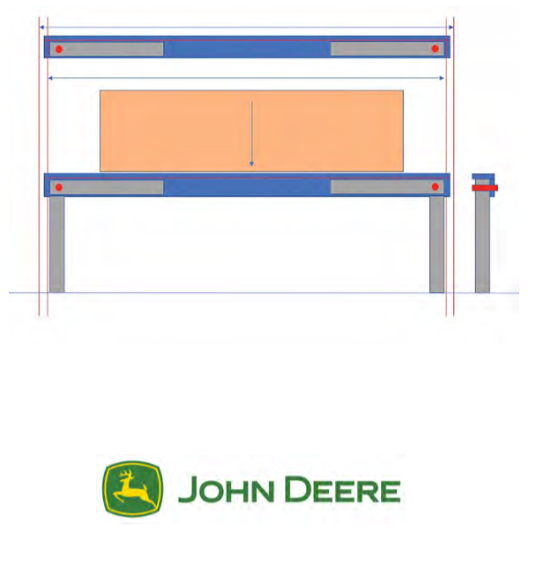

John Deere: Consolidated Warehouse Packaging Solution

John Deere has tasked our team with finding a solution regarding consolidating warehouse packaging. John Deere ships under two conditions: either weighing out the load, or cubing out the load of a shipping container.

Our project is focused primarily on cubing out the load. Currently, this proves to be difficult as it increases costs the better the container is “cubed.” The company has explored various solutions such as wooden boxes, higher stacking, reusable packaging, and several more that have all proved to be either inefficient or expensive.

The goal of this project is to come up with a pressing packing issue at John Deere; that is, find a way to efficiently consolidate a sea container. Our team is tasked with building a shelf. This shelf must be able to maximize density of the shipping container while doing so cost effectively, ergonomically sound, as well as allowing flexibility for various shipping loads.

With the presentation of multiple prototypes and their respective cost analyses, the goal is to successfully pack the shipping container to reduce John Deere’s shipping costs and strive to meet their sustainability goals. This project is focused only on shipping overseas with specific sized shipping containers, and primarily cardboard boxes, ultimately maxing out the weight at 40,000 pounds.

John Deere: Supplier Performance Predictability Tool

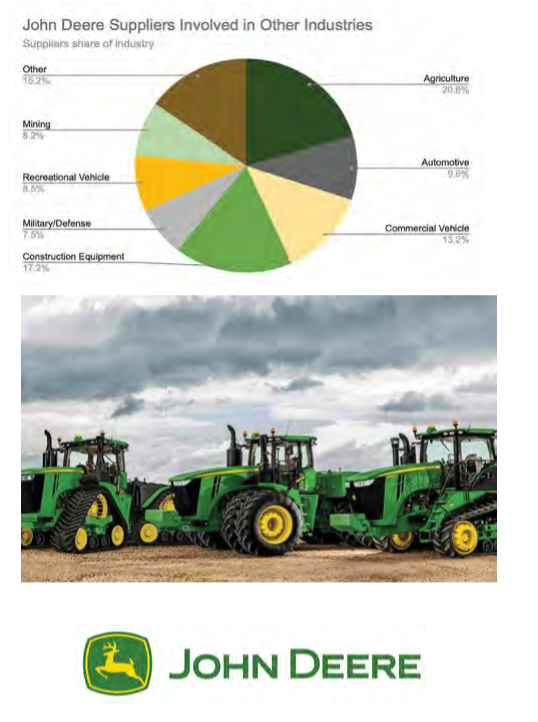

John Deere is an American corporation that manufactures construction equipment, diesel engines, agricultural machinery, axles, transmissions, and gearboxes that are used in heavy equipment and tools. This diverse supplier network combined with cyclical and seasonal business cycles has led John Deere to experience difficulties predicting supplier delinquency. The current system in place collects supplier performance and reliability data biannually. The infrequency in data collection causes supplier information to become out of date almost immediately. This creates a gap in the accuracy of the information, requiring John Deere to spend more time directly communicating with suppliers to meet business needs. Additionally, there is a need to relate current industry trends to John Deere’s own supply base to produce a more lean and robust supply chain.

The Supplier Performance Predictability Tool uses specific metrics and equations to relate John Deere’s internal supplier survey to external industry trends. These external data sources include the following industries: construction, raw materials, mining, commercial and recreational vehicles, automotive, military, and agriculture, as well as unemployment trends. This tool has in-depth pages for each industry respectively, and a home summary page that captures the most significant changes across the various industries. This home page will also flag suppliers most susceptible to risk, based on the current industry trends. Therefore, John Deere can take precautionary actions to mitigate risk across the supply chain.

The supplier predictability performance tool will provide John Deere with a centralized location to evaluate and act on supplier disruptions. Furthermore, the tool reduces dependence on direct supplier communication, which creates a more efficient process.

KLA: Michigan and Midwest Region Supply Chain Opportunities

Headquartered in Milpitas, California, KLA is a multinational company that was formed in 1997 and has around 10,500 employees and 19 global locations. KLA specializes in the semiconductor and yield management industry and strives to build innovation through factors such as communication and culture. KLA is new to the Midwest, having recently opened a site in Ann Arbor, and are looking to expand their footprint in the area. KLA is requesting three suppliers for multiple commodities including high precision machining, sheet metal, bales/harnesses, PCBAs, and contract manufacturing. Our team is responsible for researching and evaluating suppliers in the Michigan/Midwest region to present best-in-class vendors to KLA. The goal is to increase the company’s presence in the local community through the creation of jobs and increased spend in the region, reduce lead times and cost, and improve quality.

KLA’s business model consists of high mix, low volume products. The products they make are very specific and unique, so their suppliers must be able to accommodate with specialized components. The suppliers must also meet manufacturing KPI expectations regarding time to market, reliability, improved quality, reduced cost, and delivery performance. The suppliers will be asked to provide valid data and metrics regarding each KPI. Each potential supplier will also have to meet KLA’s supply chain sustainability program requirements, supply chain human rights policy, supply chain product compliance requirement, and supplier diversity guidelines to be considered.

The overall goal of this project is to create long-term supplier relationships with Michigan/Midwest suppliers. The team will formulate a standardized scorecard that will evaluate multiple suppliers at once. At the end of the semester our findings will be presented to KLA, and from there they will choose their preferred supplier(s).

L3Harris – Combat Propulsion Systems: Transmission Ball Piston Supply System Design

L3Harris is an innovative defense contractor and

information technology service provider that strives for

the best solutions and even better results. L3Harris meets needs across air, land, sea, space, and cyber domains – while holding onto the core values of integrity, excellence, and respect.

L3Harris builds transmissions for combat vehicles. Inside the transmissions for U.S. tanks and other fighting vehicles, a very high degree of precision is needed to fit the piston balls into the cylinder blocks. With such little room for failure and a crucial customer base, this is an issue that needs a solution. As an example of how tight tolerances can be, a 1-degree shift in temperature may prevent the product from being assembled correctly.

With the high precision that is needed, this is the core problem that the team is trying to solve. L3Harris needs a way to get the suppliers’ process yields to match what they require day by day. The current ordering process relies on weekly meetings with supply chain and manufacturing to order products on a weekly basis. Currently, they also don’t have a way to determine the exact products they are using, which results in instability and excess inventory.

The team’s goal for the project is to design a production system that will streamline operations by creating a more efficient system for ordering, fulfillment, and managing inventories for a product that requires very high precision. Our team needs to figure out how to reduce waste, eliminate excess inventory, and free up working capital. Within this project, costs for both the supplier and the buyer should be minimized.

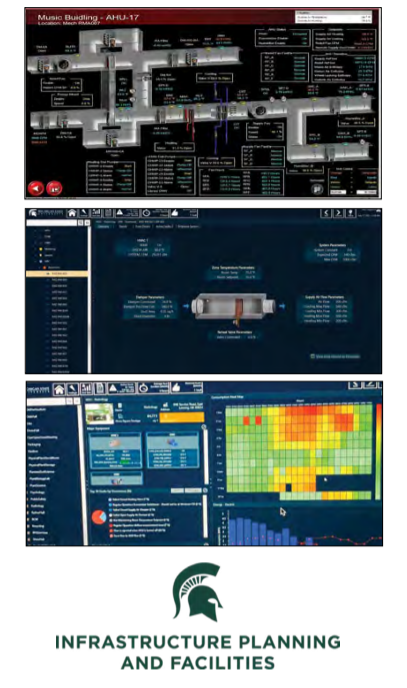

MSU Infrastructure Planning and Facilities: Energy Efficiency and Operations Dashboard

Michigan State University’s Infrastructure Planning and Facilities Department covers all of the things that keep MSU running smoothly and efficiently. The Building Performance Department oversees all of the buildings on campus and monitors how they are running and where there are problems, if any. Currently there are approximately 150 main campus buildings that are being monitored with direct controls, 25% of which have control and monitoring at the room level. The IPF Building Performance Services Central Control team is currently preparing to implement an Automatic Fault Detection and Diagnostics (AFDD) system, using a platform known as ICONICS. Operational data monitoring, virtual metering, automated fault rule development and utility data visualization development are underway. However, the creation of an all encompassing dashboard is an area that needs improvement.

This project is aimed at developing a campus-wide dashboard for the

purpose of displaying energy efficiency and operations. The final dashboard will ideally have the ability to identify where reductions can be made in overall energy usage by the heating, ventilation, and air conditioning (HVAC) systems in buildings. The dashboard will also include new ideas proposed to improve quality of life for people on campus. It was decided, based on sponsor suggestions, to highlight a few particularly insightful buildings on campus on the dashboard, which could in the future be rolled out for all buildings campus-wide. The chosen spotlight buildings encompass the many types of rooms that MSU has to offer including classrooms, lecture halls, labs, student dorms, dining halls, and study areas, as well as sports arenas. This dashboard is intended to highlight past sustainability efforts, as well as ideas for potential new efforts through improved facility operational efficiency. Various dashboard models will be proposed for consideration by the various stakeholders across MSU (students, faculty, Administration, IPF, RHS, etc.).

MSU Infrastructure Planning and Facilities: Preventative Maintenance Program on Airflow Measuring Stations

MSU Infrastructure and Planning Facilities (IPF) oversees the maintenance of all buildings across Michigan State University’s campus. One of MSU IPF’s responsibilities is to monitor the airflow measuring stations (AFMS) in over 700 heating, ventilation, and air conditioning (HVAC) systems across campus. These systems can become uncalibrated over time, however routine maintenance of airflow measuring stations is costly and time-consuming, especially when it is unnecessary.

The overall goal of the project is to determine the most costeffective methodology for maintaining devices that control the correct amount of airflow for each facility across campus. The proposed methodology would reduce overall costs of the HVAC systems by allowing them to operate as efficiently and sustainably as possible. It would also decrease the need for maintenance by transitioning from a time-based maintenance approach, suggested by the AFMS manufacturers, to a demand-based maintenance approach by utilizing fault detection and diagnostic technologies. These changes would provide value by lowering the energy consumption of the HVAC systems, ensuring healthy indoor air quality, and maintaining a more accurate system operation.

The final deliverable of the project is a proposed business case presented to IPF with cost and efficiency comparisons between new AFMS options, recommendations on how to better control pressurization, as well as methods for leveraging fault detection and diagnostics technology to ensure calibration of the AFMS devices.

NASA Psyche Mission: NASA Creativity Competitions

The NASA Psyche Mission is scheduled to launch in late summer 2022. Since the appearance of the 16 Psyche asteroid remains unknown, NASA is looking to host a competition to give the public an opportunity to imagine and share their interpretations of what the asteroid will look like. Our team has been tasked with conducting research and analysis on previous NASA creative competitions to make recommendations about how the Psyche mission can develop a similar competition that will reach a wide audience and increase public awareness. To make the best recommendations, we will compare the procedures, rules, promotional efforts, and the outcomes of various past competitions. Identifying methods that have been most effective in the past will allow us to deliver the best suggestions for the Psyche Mission competition.

This project grants our team the opportunity to inspire

people about the possibilities of space exploration and

science. There is also the prospect of generating awareness

and interest in the NASA Psyche Mission. Through the completion of this project, the team aims to get the public’s

input on what they believe the Psyche asteroid looks like and

simultaneously engage students to push their creativity and learn more about space exploration.

NASA Psyche Mission to a Metal World: Launch Lead Up Analysis

The NASA Psyche mission is a unique space endeavor to a metallic asteroid between Mars and Jupiter known as 16 Psyche. For the first time, NASA will explore a world made largely of metal rather than rock or ice. Psyche could possibly reveal how the Earth’s core and the cores of other terrestrial planets were formed. Psyche is the only known place in our solar system where we can directly examine what may be remnant core material from an early planet. The goal of the Psyche mission is to understand previously uncharted territory: early planetary formation. NASA plans to launch the robotic Psyche orbiter in August 2022. The orbiter would travel to Psyche, arriving in early 2026, where it would then orbit for a primary mission of almost two years, collecting data.

The Psyche mission is led by Arizona State University and 15 additional partners. For the past five years, university students from all over the United States have taken part in capstone projects relating to the Psyche mission. Each capstone team plays a unique

part in the overall mission of Psyche. Our team will contribute to this project by delivering the NASA Psyche mission a comprehensive list of marketing strategies validated through a research-backed criteria system. By conducting market research of specified cohorts of the target audience, the general public, this validation system for assessing marketing strategies and potential efficacy will assist the Psyche teams and future space endeavors in appraising future launch lead-up and coverage engagement campaigns.

The proposed ideas should encompass the mission Principal Investigator’s statement: “Inspire people to be bolder.” The engagement activities and strategies should seek to encourage individuals to be bolder in their own lives, much like the heart of the Psyche mission itself, a bold and innovative space endeavor.

Parker Hannifin: The Indirect Course

Parker Hannifin, founded in 1917, started as a control system company for automobiles and newly invented aircrafts, but has since transformed into a world leader in not only the manufacturing of motion and control technologies and systems, but also n providing precision-engineered solutions for a wide variety of mobile, industrial, and aerospace markets. Recently, Parker Hannifin celebrated its 100th anniversary and is looking towards the next century in every way! Highlighting this with the saying “Engineering your success,” supporting its promise to customers to increase their productivity and profitability.

However, along with the continued rise in success of the company, the cost of indirect materials has also risen to staggering levels. Parker Hannifin recently started utilizing a business-2-business sourcing tool called Ariba that presents multiple purchasing options when procuring these indirect materials. Our team has been tasked to develop or improve a new or existing way to calculate these indirect savings that Ariba finds.

The project is focused on the evaluation of Ariba’s capacity to determine savings, develop methodologies to determine savings gained through the use of Ariba vs using open sourcing from various distributors, and providing calculated savings sheets to justify the use and operations of Ariba.

In other words, our team is going to provide a system that will accurately determine if Parker Hannifin is saving money on indirect materials through Ariba.

The project will be completed by designing and implementing a scheme that will compare the past purchase history of the company, through Ariba, against the current market prices that can be found through multiple different distributors, resulting in a calculated savings sheet. Through the implementation of this system, key variances between indirect spending and potential cost savings will be better identified and will result in a better way to track, report, and hopefully further reduce spending

Smith+Nephew: Replenishment Optimization Initiative

Established in 1856 in England, Smith+Nephew has been designing and producing medical equipment for hospitals for 165 years. Smith+Nephew is a publicly traded company that is a well-respected leader in their industry. Their products are categorized into three larger franchises: Advanced Wound Management, Orthopedics & Trauma, and Sports Medicine. They produce an innovative range of products, such as their Hip and Knee Implants from Orthopedics, used in replacement and trauma surgeries. Smith+Nephew operates and ships products to every continent except Antarctica. Their goal is to restore people’s bodies and their self-belief by removing limits to living.

Our team was tasked to develop a more efficient replenishment system that optimizes the current Smith+Nephew replenishment process. We focused on optimizing the replenishment of certain orthopedic products, such as hip or knee implants, within a given district. Being focused on certain products in a certain district will allow us to produce a fully vetted replenishment optimization solution that can be adopted into supply chains of their other products and districts. The ultimate goal of the initiative is to produce various cost reductions by reducing on-hand inventory. The reduction in on-hand inventory will generate a higher inventory turnover for Smith+Nephew, which will allow them to reach their goal of a more optimized supply chain. This process will be the model for a more efficient process and will have a positive impact across the entire Smith+Nephew’s supply chain.

Smithfield Foods: Automated Trailer Loading Savings Potential

Smithfield Foods is a pork producer and food-processing company located in Smithfield, Virginia. Since being founded in 1936, Smithfield has grown to become the world’s largest pork processor in the world, the largest hog producer in the United States, and a leader in several packaged meats categories.

Smithfield’s long-term deliverable is enhanced customer service at the reduction of direct labor. Smithfield aims to achieve this by reducing both trailer load times and damaged goods, together with an increase in customer order accuracy. Along with this, through the use of automated machinery, direct labor is reduced.

Smithfield’s current trailer loading process takes about an hour. Because of this slow process, Smithfield has searched for and identified a piece of machinery, the Ancra Skateloader (shown at the right), that would load trailers in under 10 minutes, resulting in potential time savings of nearly 40-50 minutes. Similar to a conveyor belt, the machine would gently place a trailer’s worth of pallets down at once.

Smithfield has tasked our team with the proposal of implementing this automated loading machine into their distribution facility. Our team’s responsibility is to research and analyze whether the equipment aligns with Smithfield’s current goals, future goals, and their long-term customer service deliverable. With the identification of the automated machinery, our team must conduct a cost-benefit analysis weighing direct labor wages against the purchase, installation, and general maintenance cost of the Skateloader. The cost-benefit analysis will determine whether or not the machinery eliminates the cost of enough labor. Along with this, our team must decide whether or not the implementation of the Skateloader accomplishes the quantitative goals within order accuracy, trailer turn times, and the percentage of damaged goods that the sponsor is striving to achieve.

With the implementation of the machinery, our team must also account for the rework of the process flow map and outbound dock layout.

Trane Technologies: Indoor Air Quality Category Approach

Trane Technologies is a company that focuses on solving sustainability challenges through innovation in the heating and cooling industry. Trane Technologies develops commercial HVAC systems, residential HVAC, and transportation refrigeration systems. Serving many different industries including the hospitality industry, the Federal Government, commercial real estate, data centers, healthcare, restaurants, and education, Trane Technologies has a great opportunity to provide customers with needed value through environmentally responsible products and services.

Before COVID-19 interrupted normal business processes, HVAC companies had focused a great deal on energy efficiency and comfort with respect to the systems they developed. With the emergence of the virus, a shift in focus towards indoor air quality (IAQ) has emerged. This great shift in demand and mix of IAQ solutions has forced Trane Technologies as well as competitors in the industry to make rapid adjustments.

In order to assist Trane Technologies in their goal to provide customers with much needed solutions to solve IAQ challenges, our team was assigned a project to propose an overall category approach for IAQ products. The goal of the category approach is to provide Trane Technologies with insights on how to optimally source IAQ products in order to leverage global spend and meet business objectives and innovation.

This project required a great deal of research in terms of understanding the current spend of the company in relation to IAQ products. It also took an understanding of the company’s supply market for IAQ products. Putting together all of the insights gained from data, conversations with internal members of Trane Technologies, as well as conversations with external suppliers, has allowed us to develop an overall category approach and provide external insights to Trane Technologies on how to optimally source and manage IAQ products.